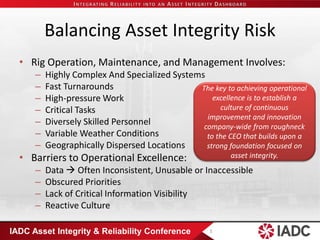

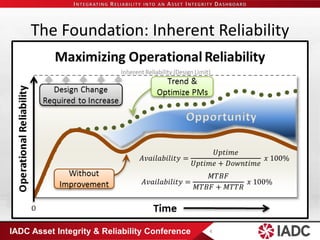

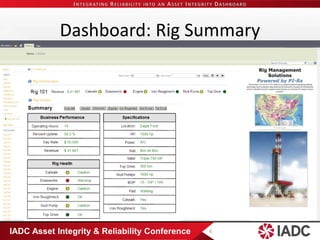

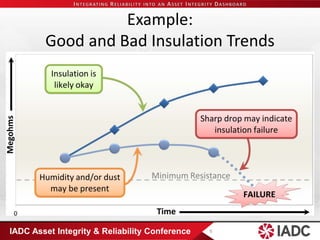

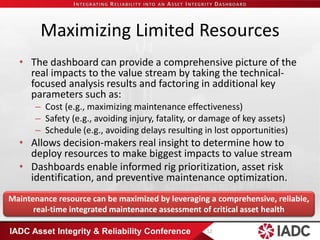

The document discusses the integration of reliability into an asset integrity dashboard to enhance operational excellence in rig operations. It highlights the importance of continuous improvement and a culture that engages all personnel, as well as steps to create an effective dashboard that maximizes resources and provides critical insights. By combining asset integrity data with financial metrics, businesses can make informed decisions that reduce downtime and improve safety and performance.