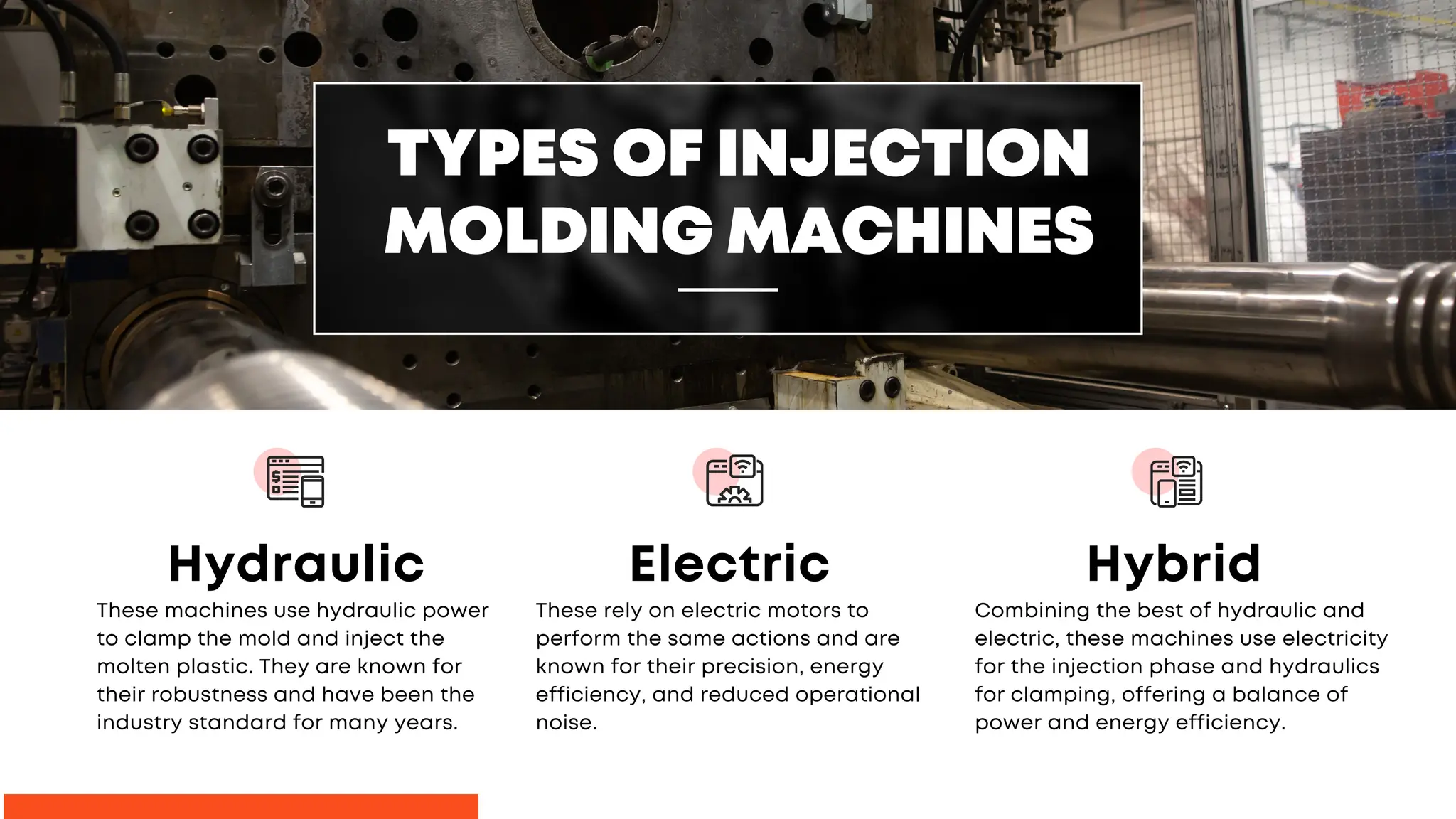

Plastic injection molding is a key manufacturing process that involves injecting molten plastic into molds to create complex products efficiently. The evolution of this technology has led to sophisticated methods that cater to various industries, including automotive and medical devices. Despite its advantages like design flexibility and high production rates, challenges such as high initial costs and design limitations must be considered.