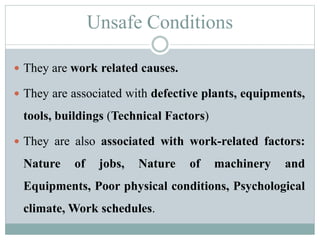

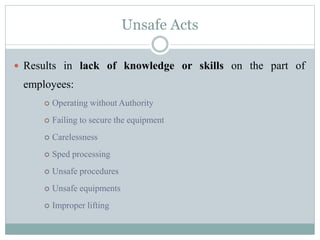

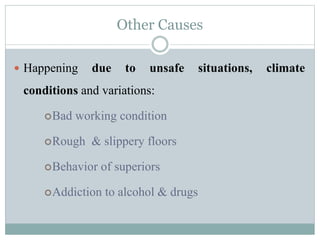

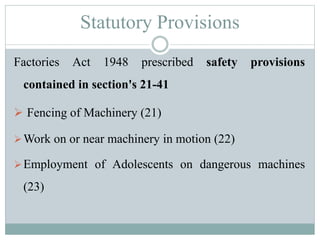

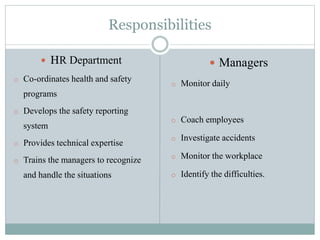

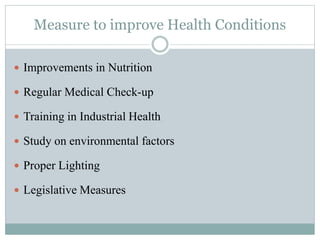

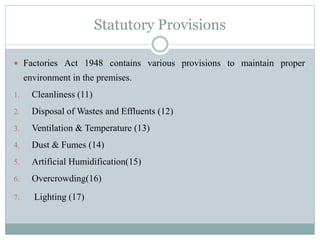

The document discusses industrial accidents, their causes, and methods of prevention. It notes that industrial accidents are unplanned events that result in physical injury making an employee unfit for work for at least 48 hours, as defined by the Factories Act of 1948. Accidents typically result from a combination of unsafe conditions like defective equipment, and unsafe acts like operating machinery without authority. The document also outlines responsibilities and statutory provisions to improve industrial health and safety conditions.