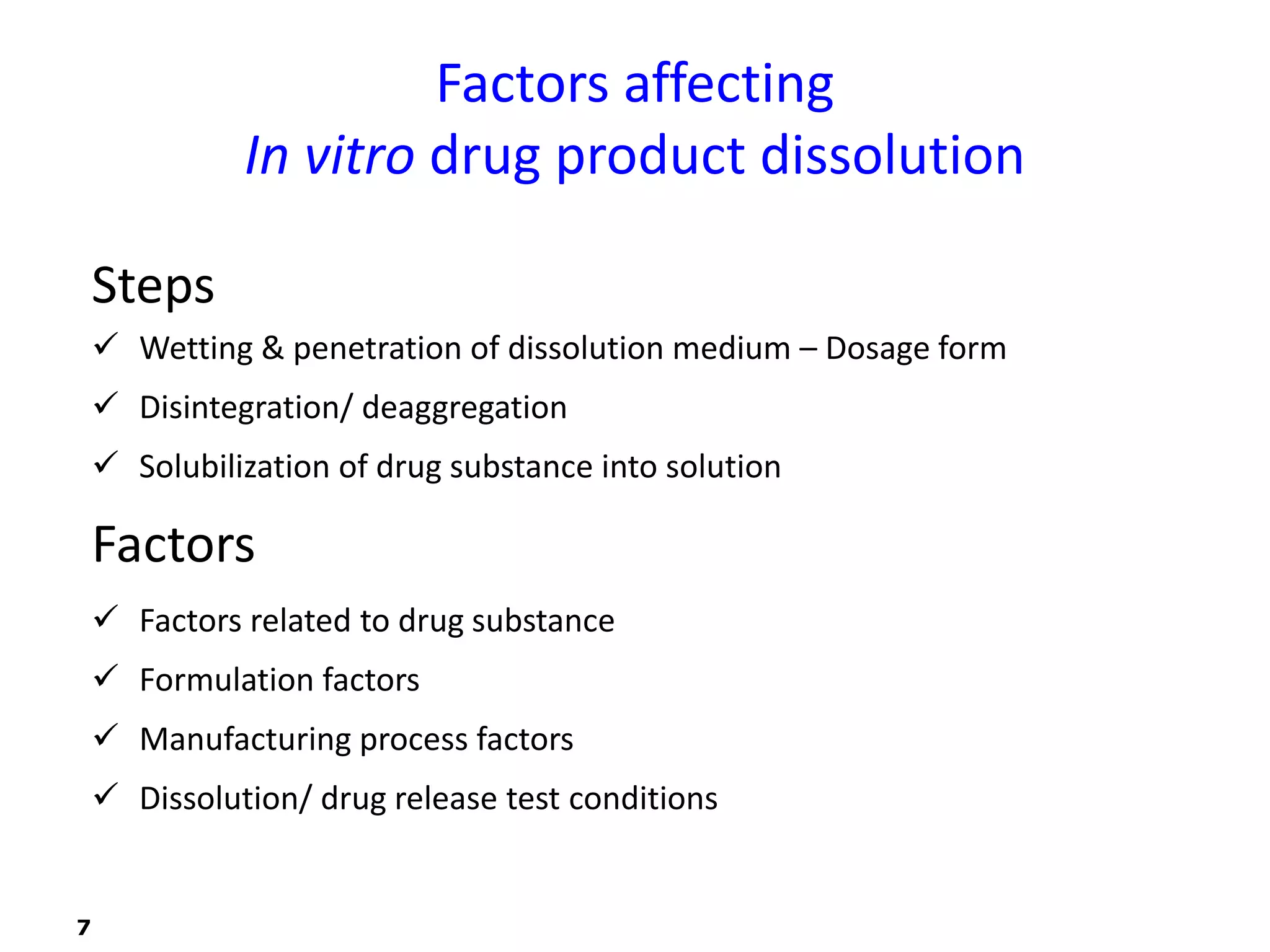

This document discusses in vitro drug product performance characterization and dissolution testing of solid oral dosage forms. It describes the importance of in vitro testing in predicting in vivo drug absorption and performance. The key factors that can affect drug dissolution are described, including drug substance properties, formulation composition, manufacturing processes, and test conditions. Common dissolution apparatus, media, and acceptance tolerances used in testing immediate release solid oral drug products are also summarized.

![FACTORS RELATED TO DRUG SUBSTANCE

Dissolution - Solubilization of drug into dissolution medium

Control – affinity b/n solid & disso lutionmedium, as diffusion of drug into

bulk liquid media

Noyes and Whitney equation

dm/dt = K (Cs-Ct)

(Cs-Ct) – conc gradient b/n diffusion layer & bulk soln

Brunner & Tolloczko incorporated S

dm/dt = K’ x S (Cs-Ct)

S – Surface area, K’ – constant to chemical subs

Brunner expanded scope – included Nernst’s theory

Dc/dt = [DS/Vh] x (Cs-Ct)

D – Diffusion coefficient, h – thickness of diffusion layer, V –dissolution

volume

Drug dissolution – inflUenced by solubility, diffusivity, SA and solution

hydrodynamics

8](https://image.slidesharecdn.com/invitrodrugproductperformance-230714041538-7df2358a/75/In-Vitro-Drug-Product-Performance-ppt-8-2048.jpg)