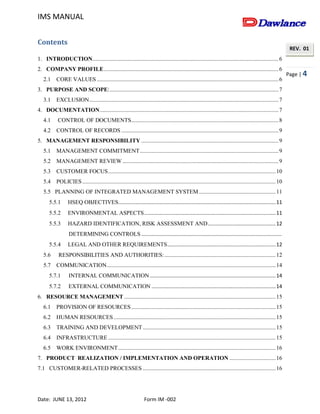

This document is the Integrated Management Systems Manual for Dawlance Group of Companies (DGC) dated June 13, 2012. It describes DGC's health, safety, environmental, and quality management systems which are based on ISO 9001, ISO 14001, and OHSAS 18001. The manual outlines the purpose, scope, documentation procedures, management responsibilities, resource management, product realization processes, measurement and improvement processes for DGC's integrated management system. It is intended to ensure that customer and legal requirements are met and that products are manufactured in a quality, safe, and environmentally friendly manner.