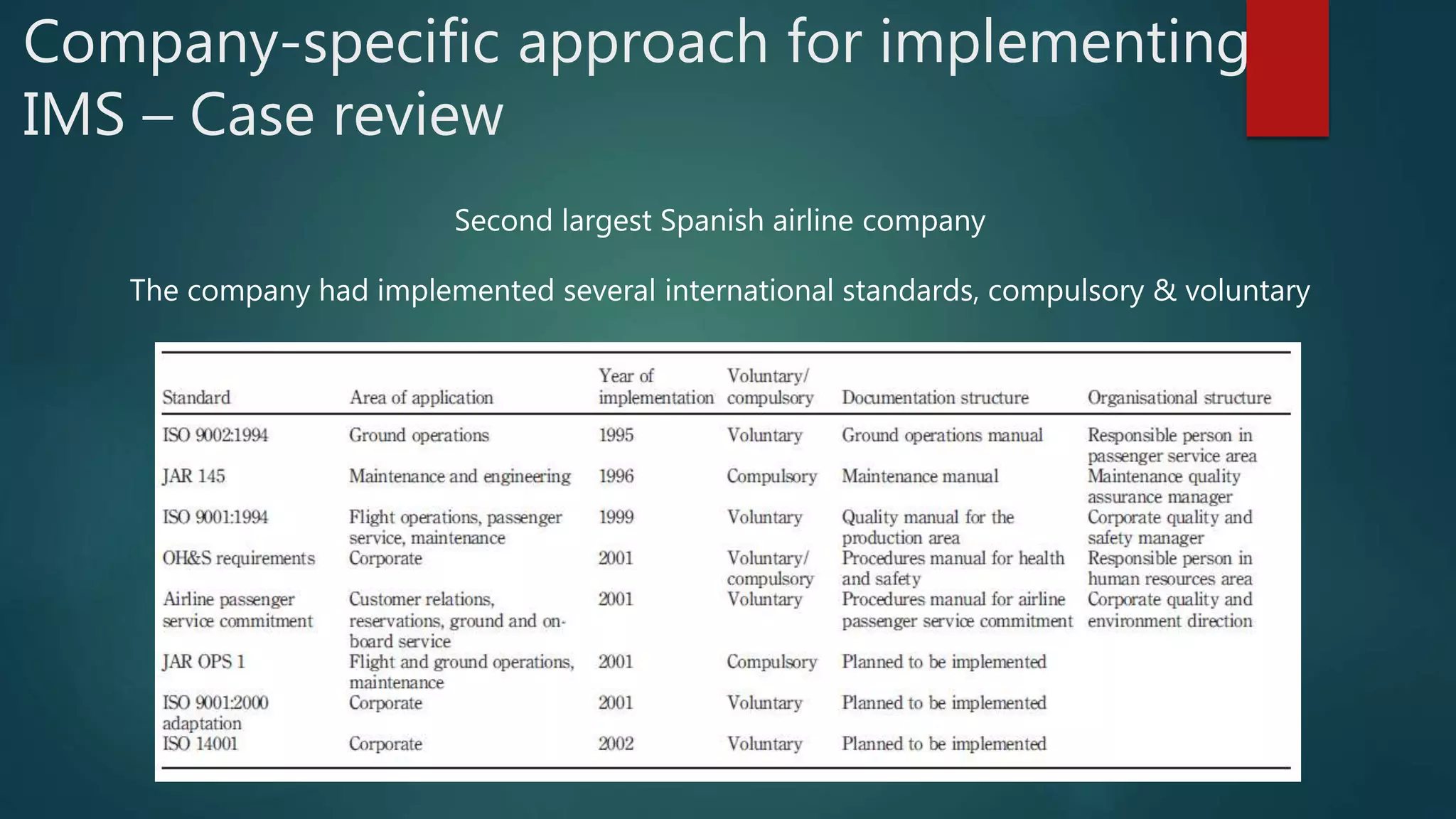

The document discusses integrated management systems (IMS) and their definitions, examples, and benefits, emphasizing the importance of integrating multiple management systems to improve organizational efficiency. It presents a case study of a Spanish airline that faced fragmentation due to separate management systems, leading to inefficiency and poor performance, and outlines steps taken to integrate these systems into a holistic IMS. The implementation included creating a corporate quality manual and utilizing various guidelines and tools for ongoing performance evaluation.

![Some numbers for rigor

95% of firms report internal benefits [Iowa State University] –

Greater employee awareness

Increased operational efficiency

Reduced scrap expense

85% report external benefits [Dun and Bradstreet] -

Higher perceived quality

Greater customer demand

100 firms reported [Irwin Professional Publishing]

Average improvement in their operating margin was at 5% of sales](https://image.slidesharecdn.com/integratedmanagementsystems-151110184321-lva1-app6892/75/Integrated-management-systems-5-2048.jpg)