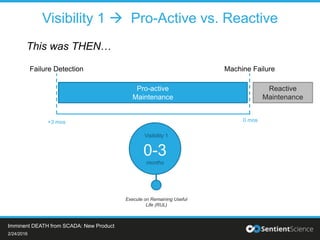

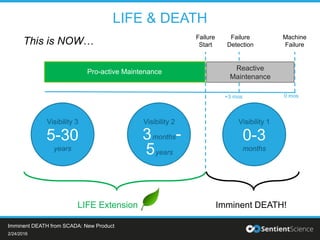

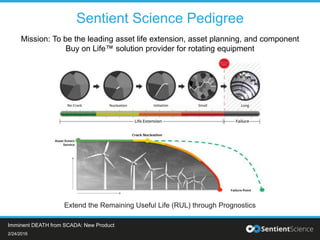

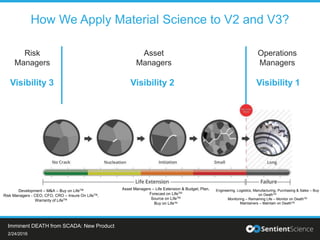

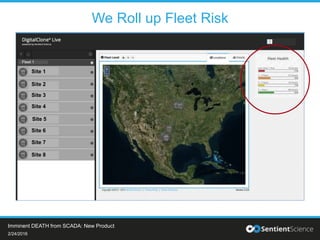

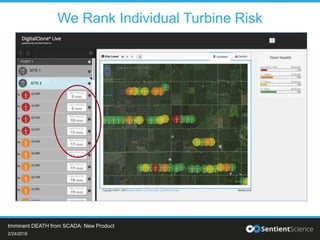

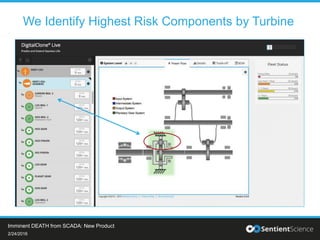

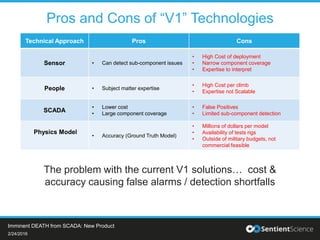

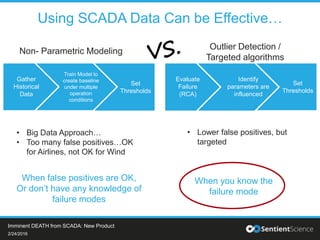

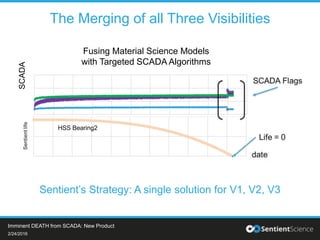

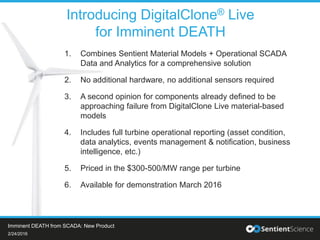

The document discusses the introduction of a new product aimed at improving asset management and life extension for rotating equipment by providing various levels of visibility into asset failures. It emphasizes the need for a proactive maintenance approach, using prognostics to extend the remaining useful life of components while reducing false positives associated with traditional monitoring methods. The solution integrates material science with operational data, positioning it as a comprehensive approach for risk management in asset operations.