Ijifr v4-e2-007

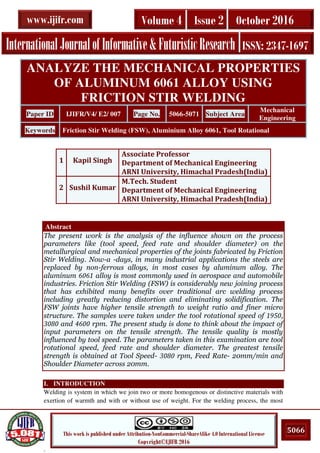

- 1. . 5066This work is published under Attribution-NonCommercial-ShareAlike 4.0 International License Copyright©IJIFR 2016 InternationalJournalofInformative&FuturisticResearch ISSN: 2347-1697 Volume 4 Issue 2 October 2016www.ijifr.com Abstract The present work is the analysis of the influence shown on the process parameters like (tool speed, feed rate and shoulder diameter) on the metallurgical and mechanical properties of the joints fabricated by Friction Stir Welding. Now-a -days, in many industrial applications the steels are replaced by non-ferrous alloys, in most cases by aluminum alloy. The aluminum 6061 alloy is most commonly used in aerospace and automobile industries. Friction Stir Welding (FSW) is considerably new joining process that has exhibited many benefits over traditional arc welding process including greatly reducing distortion and eliminating solidification. The FSW joints have higher tensile strength to weight ratio and finer micro structure. The samples were taken under the tool rotational speed of 1950, 3080 and 4600 rpm. The present study is done to think about the impact of input parameters on the tensile strength. The tensile quality is mostly influenced by tool speed. The parameters taken in this examination are tool rotational speed, feed rate and shoulder diameter. The greatest tensile strength is obtained at Tool Speed- 3080 rpm, Feed Rate- 20mm/min and Shoulder Diameter across 20mm. I. INTRODUCTION Welding is system in which we join two or more homogenous or distinctive materials with exertion of warmth and with or without use of weight. For the welding process, the most ANALYZE THE MECHANICAL PROPERTIES OF ALUMINUM 6061 ALLOY USING FRICTION STIR WELDING Paper ID IJIFR/V4/ E2/ 007 Page No. 5066-5071 Subject Area Mechanical Engineering Keywords Friction Stir Welding (FSW), Aluminium Alloy 6061, Tool Rotational 1 Kapil Singh Associate Professor Department of Mechanical Engineering ARNI University, Himachal Pradesh(India) 2 Sushil Kumar M.Tech. Student Department of Mechanical Engineering ARNI University, Himachal Pradesh(India)

- 2. 5067 ISSN: 2347-1697 International Journal of Informative & Futuristic Research (IJIFR) Volume - 4, Issue -2, October 2016 Continuous 38th Edition, Page No: 5066-5071 Kapil Singh, Sushil Kumar :: Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding essential base is heat. There are two sorts of There are two sorts of welding i.e. conventional welding and stir welding. Here we talk about the Friction Stir Welding (FSW). The concept of FSW is simple in which A non-consumable rotating tool with a specially designed pin and shoulder is inserted into the abutting edges of sheets or plates to be joined till the shoulder contact the top surface of work piece and traversed along the line of joint to produce the weld(Fig1). The tool serves primary functions: a) heating of work piece; b) deform the material ; c) movement of deform material to produce the joint. Aluminium is one of the most common alloys which is widely used in several application over the automotive and aircraft industries because of their light weight properties, better corrosion resistant and high strength to weight ratio. Figure 1: Friction Stir Welding FSW have the advantages over conventional welding are: Strong mechanical properties Fine grain structure, revising power, decrease lingering hassle, pliability, and imperviousness to erosion. Dissimilar material can be joined. Guarantee 100% weld quality. II. LITERATURE SURVEY Jaimin B. Patel etal.(2014), This paper introduces the demonstration of FSW devices by substitution of hardware pin profile alongside recreation of crest temperature instigated in plate material and stream hassles produced in the same for friction welding of AA6061. Results are introduced for different temperatures of aluminum compound plate and in addition stream hassles are produced in and around the instrument pin during the welding procedure.

- 3. 5068 ISSN: 2347-1697 International Journal of Informative & Futuristic Research (IJIFR) Volume - 4, Issue -2, October 2016 Continuous 38th Edition, Page No: 5066-5071 Kapil Singh, Sushil Kumar :: Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding A M Khourshidetal.(2013), In this research work, friction welding is connected with the combination of two channels, meager walled thickness variably empty glass of the gloves. The main focus of this work is studying the impact on the mechanical properties of the welding joints. B.Kiran Kumar etal.(2016), This research work is about the study of mechanical properties and micro-structure on FSW aluminum alloy. By this study we came to know that the pin diameter and shoulder diameter are increased with the increase in thickness of the plates or specimen undergoing the process of FSW. III. EXPERIMENTAL PROCEDURE In the welding process, we require a pivoting device with a shoulder and a stick that produces heat and encourages the stream of the diminished strong compound behind the apparatus where the welded joint structures.The Taguchi Method will be utilized to discover the three blend welding parameters. In this work three parameters will be taken and L9 orthogonal cluster will be chosen to advance parameters for quality of the welded joint.We take the different parameter to achieve the greatest tensile strength. The parameters are tool speed, feed rate and shoulder diameter. Table 1 shows the process parameters: Table 1: Process Parameters Level Tool Speed(rpm) Feed Rate(mm/min) Shoulder Dia. (mm) 1 1950 20 17 2 3080 25 19 3 4600 30 21 Tensile Strength calculation: Maximum St�ength = Maximum Load KN Maximum A�ea ��2 For conversion of kgf into N/mm2 :1 kgf = 9.8 N/mm2 Elongation calculation: Elongation = Change in Length ∗ Holding Length IV. RESULTS AND DISCUSSION We performed nine experiments in the first run and universal testing machine is used to calculate the tensile strength. The calculated tensile strength is shown in the table-2.The tensile strength is calculated for the different parameters such as tool rotation speed, feed rate and shoulder diameter. Table 2: Tensile strength Trial 1 of the Specimens for Single Sided Joint Speed(r.p.m) Sample No. Feed (mm/min.) Shoulder Diameter(mm) Area (mm2 ) Load (KN) Tensile strength Trial1 (KN/mm2 ) 1950 S1 20 16 150 9 0.06

- 4. 5069 ISSN: 2347-1697 International Journal of Informative & Futuristic Research (IJIFR) Volume - 4, Issue -2, October 2016 Continuous 38th Edition, Page No: 5066-5071 Kapil Singh, Sushil Kumar :: Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding S2 25 18 150 11.25 0.074 S3 30 20 150 18.5 0.124 3080 S4 20 18 150 20 0.133 S5 25 20 150 23.9 0.17 S6 30 16 150 17.7 0.118 4600 S7 20 20 150 17.20 0.116 S8 25 16 150 7.6 0.054 S9 30 18 150 8 0.048 Now we calculate the elongation for each nine specimen shown above at different parameters such as feed rate, transverse speed and shoulder diameters is shown in the table: 3. Table 3: Change in Length& Elongation Figure 2: Effect of Welding Parameters on Tensile Strength for S/n ratio Speed (r.p.m) Sample No. Holding length (mm) Change in length (mm) Elongation (%age) 1950 S1 50 5.5 12 S2 50 7 15 S3 50 8 17 3080 S4 50 6.5 14 S5 50 7.5 16 S6 50 5 11 4600 S7 50 3.5 8 S8 50 3.5 6 S9 50 3 7 460030801950 -18.0 -19.5 -21.0 -22.5 -24.0 302520 201816 -18.0 -19.5 -21.0 -22.5 -24.0 Tool Speed MeanofSNratios Transverse Speed Shoulder Diameter Main Effects Plot for SN ratios Data Means Signal-to-noise: Larger is better

- 5. 5070 ISSN: 2347-1697 International Journal of Informative & Futuristic Research (IJIFR) Volume - 4, Issue -2, October 2016 Continuous 38th Edition, Page No: 5066-5071 Kapil Singh, Sushil Kumar :: Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding After using all the observation as given in table 2 and table 3 means and S/N ratio are calculated and the analysis is shown by the various graph is drawn by Minitab 15 software. The S/N ratio for Tensile Strength is calculated on Minitab 15 Software using Taguchi Method. A greater S/N value corresponds to a better performance. Figure 3: Effect of Welding Parameters on Tensile Strength for Means V. DISCUSSION Taguchi method stresses the importance of studying the response variation using the signal– to–noise (S/N) ratio, resulting in minimization of quality characteristic variation due to uncontrollable parameter. The Tensile strength was considered as the quality characteristic with the concept of "the larger-the-better". The S/N ratio for the larger-the-better is: S/N = -10� � { ∑ � } Finally we got the optimum value of parameters of welding process for maximum tensile strength which is given in Table 4. Table 4: Optimum Value of Parameter According to S/N Ratio Tool Speed (rpm) Feed Rate (mm/min) Shoulder Diameter (mm) Tensile strength (KN/mm2 ) 3080 20 20 0.164 VI. CONCLUSION For better welding issues, so many different traditional strategies had been utilized in this way, yet they are not vigorous and have many limitations. To solve the above issues, Taguchi system is utilized as a part of this research. The Tensile quality is mostly influenced by Tool speed and next to it shoulder distance across & feed rate likewise influence to some

- 6. 5071 ISSN: 2347-1697 International Journal of Informative & Futuristic Research (IJIFR) Volume - 4, Issue -2, October 2016 Continuous 38th Edition, Page No: 5066-5071 Kapil Singh, Sushil Kumar :: Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding degree. The Parameters considered in the examinations are upgraded to accomplish greatest Tensile Strength. The best setting of information procedure parameters for greatest tensile Strength is Tool speed-3080 rpm, feedrate-20 mm/min, and Shoulder diameter across 20 mm. VII. REFERENCES [1] A. Arora(2011) "Toward ideal erosion blend welding instrument shoulder diameter" Materials and Design,Vol. 64, pages: 9–13. [2] A.Govind Reddy (2012) "Process Parameter Optimization for Friction Stir Welding of disparate Aluminum Alloys" International Journal of Engineering Research & Technology vol.2, ISSN: 2278-0181 [3] A.Heidarzadeh and H. Khodaverdizadeh (2012)"Tensile conduct of friction blend welded AA 6061-T4 aluminum composite joints" Materials Science and Engineering vol. 37 page: 164– 173 [4] Ajay Kumar Revuri(2012)" Computational Analysis Of Friction Stir Welding Tools With Various Threaded Pin Profiles" International Journal of Engineering Research & Technology vol.2, ISSN: 2278-0181 [5] A M Khourshid (2013) "investigation and outline of grinding stir welding" International diary of mechanical designing and automated exploration India vol. 2 page: 1820– 1829 [6] D.M. Rodrigues and A. Loureiro (2012) "Impact of friction blend welding parameters on the microstructural and mechanical properties of AA 6016" Materials Science and Engineering vol. 30 page: 1913– 1923. [7] Dongun Kim (2010) "friction mix welding", mix. European Journal of Mechanics A/Solids, Vol. 29, pages: 207–215 [8] G. Çam(2008) "Mechanical properties of contact stir butt-welded Al-5086 H32 plate" Journal of Achievements in Materials and Manufacturing Engineering vol. 30 page: 135– 142 [9] Gopi Chand (2013) "Utilization of Taguchi Technique for Friction Stir Welding of Aluminum Alloy AA6061" International Journal of Engineering Research & Technology vol.6, ISSN: 2278-0181 [10] H.J. Liu (2009) "Malleable properties and crack areas of friction blend welded joints of 2017-T351 aluminumalloy"Journal of Materials Processing Technology vol 142, page: 691– 696 [11] Indira Rani M and Marpu R.N (2011) "An investigation of procedure parameters of friction mix welded aa 6061 aluminum amalgam" Journal of Engineering and Applied Sciences vol. 6, pp. 1819-6508 To Cite This Article Singh,K., Kumar,S.(2016): “Analyze The Mechanical Properties Of Aluminum 6061 Alloy Using Friction Stir Welding” International Journal of Informative & Futuristic Research (ISSN: 2347-1697), Vol. 4 No. (2), October 2016, pp. 5066-5071, PaperID: IJIFR/V4/E2/007.