HARDNESS, FRACTURE TOUGHNESS AND STRENGTH OF CERAMICS

- 1. HARDNESS, FRACTURE TOUGHNESS AND STRENGTH OF CERAMICS Akumalla Rajkumar 120CR0396 1 SEMINAR AND TECHNICAL WRITING

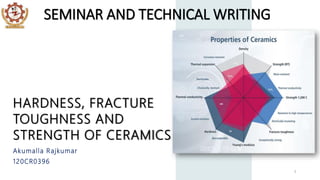

- 3. INTRODUCTION • Ceramics are a diverse class of materials valued for their unique properties. They are generally known for their high hardness, making them ideal for wear-resistant applications. They are strong, durable, and often resistant to high temperatures. But how do we quantify these strengths and weaknesses? • This introduction explores three key mechanical properties that define a ceramic's capacity to withstand stress and deformation: • Hardness • Fracture toughness • Strength. 3

- 4. HARDNESS • Hardness, itself, is not uniquely defined. In the most general sense it refers to a materials resistance to penetration by a sharp object. • Hardness is a measure of the material’s resistance to localized plastic deformation (e.g. dent or scratch) • A qualitative Moh’s scale, determined by the ability of a material to scratch another material: from 1 (softest = talc) to 10 (hardest = diamond). • Different types of quantitative hardness test has been designed (Rockwell, Brinell, Vickers, etc.). Usually a small indenter (sphere, cone, or pyramid) is forced into the surface of a material under conditions of controlled magnitude and rate of loading. The depth or size of indentation is measured. • The tests somewhat approximate, but popular because they are easy and non-destructive (except for the small dent). 4

- 5. METHODS OF HARDNESS MEASUREMENT • Two types of sharp-pointed hardness indenters: Vickers and Knoop. Vickers Hardness: • For most ceramics, the hardness value is obtained with the Vickers indentation technique using the following expression: Hv=1.8544P/(2a)^2, Hv is Vickers hardness, P is the applied load, and d is the average value of two diagonals. • Like many hardness tests, Vickers relies on the concept of indentation. A standardized indenter, typically a pyramid- shaped diamond, is pressed onto the material's surface with a specific load. The resulting indentation size reflects the material's resistance to deformation. Harder materials will produce smaller indentations under the same load. 5

- 6. • Knoop Hardness: • Only the long diagonal of the Knoop indentation is measured to determine the Knoop hardness (HK). • Knoop hardness measurements are the preferred ones for very brittle ceramics such as SiC and loads, P, not exceeding 2kg to avoid cracking. • Knoop indenters are also used to measure hardness when a small penetration depth is desired, for instance, in measuring the hardness of a coating. • Vickers and Knoop indenters normally form a chisel edge of approximately 1mm in length. • The measure of depth of penetration to determine hardness has the advantage that the depth can be measured continually to produce a load displacement (depth) curve such as the one shown in Figure 6 Typical load–displacement curve for instrumented hardness

- 7. FACTORS AFFECTING HARDNESS Mineral Composition Ceramics composed of minerals with strong interatomic bonds tend to be harder. Minerals like alumina (aluminum oxide) and silicon carbide are naturally very hard, contributing significantly to the overall hardness of the ceramic. Microstructure The microstructure refers to the arrangement and size of grains within the ceramic. Finer grain sizes generally result in higher hardness. Additionally, lower porosity leads to increased hardness. Pores act as weak points and can reduce the material's resistance to deformation. Processing Techniques The manufacturing methods used to create the ceramic can influence the microstructure and, consequently, the hardness. Techniques like hot pressing or sintering can influence the grain size and porosity, impacting the final hardness of the ceramic. 7

- 8. APPLICATIONS OF HARDNESS OF CERAMICS CUTTING TOOLS Ceramic cutting tools, like blades and inserts, are significantly harder than traditional steel tools. WEAR PLATES AND LINERS Ceramic wear plates and liners are used to protect equipment surfaces from abrasion and impact. DENTAL IMPLANTS Some dental implants utilize advanced ceramics due to their biocompatibility and exceptional hardness ARMOR Ceramic materials are sometimes incorporated into ballistic armor due to their ability to stop projectiles. SANDBLASTING NOZZLES Ceramic nozzles used in sandblasting applications utilize their hardness to propel abrasive particles at high velocities for cleaning or surface preparation. 8

- 9. FRACTURE TOUGHNESS • Fracture toughness is a critical property for ceramics, especially considering their reputation for brittleness. It goes beyond hardness to assess a material's ability to resist crack propagation. • A parameter, used to describe fracture toughness is known as critical stress Intensity, K = σ (πC)^1/2 • The stress intensity factor K describes the stress distribution around a flaw. • In brittle materials, lack of plastic deformation or yielding at the crack front, causes sufficient stress concentration to cause the crack to propagate without very little expended energy. Crack tip stress intensity >> fracture strength of the matrix in the immediate vicinity of the crack tip. • The rapid propagation of the crack from the crack tip, especially in a monolithic material results in low fracture toughness or resistance to crack propagation. 9 Typical stress-strain curves for (a) brittle solids and (b) ductile materials.

- 10. • It is also recommended that the toughness of ceramics with new compositions be measured at different loads to check whether toughness increases with crack length, leading to “ R - curve ” behavior. • It should be mentioned here that the indentation method is now routinely used for convenience to compute the fracture toughness of small and relatively brittle specimens • Once cracking starts, it is therefore rather easy for cracks to grow in ceramics. • if the interaction between a growing crack and the • microstructure can absorb a fraction of the energy available at the crack tip stress field, then the driving force for crack propagation will be lowered. • Mechanisms to improve crack growth resistance, that is, toughening mechanisms, Various toughening mechanisms in ceramic - based materials. 10

- 11. FACTORS AFFECTING FRACTURE TOUGNESS Flaws and Defects • Pre-existing cracks, voids, or other imperfections within the ceramic act as starting points for crack growth. • These flaws can significantly reduce the fracture toughness of the material. • Minimizing these defects during processing is crucial for achieving good toughness. Microstructure • Finer grain sizes generally lead to higher fracture toughness. This is because smaller grains create a more tortuous path for cracks to propagate through the material. • The presence of pores within the ceramic can act as stress concentrators, making it easier for cracks to initiate and propagate. Residual Stresses • Internal stresses within the ceramic, introduced during processing or thermal cycling, can also affect fracture toughness. • Minimizing these stresses can improve overall toughness. 11

- 12. APPLICATIONS OF FRACTURE TOUGHNESS OF CERAMICS TURBOCHARGERS AND ENGINE PARTS The fracture toughness of ceramics allows them to withstand these demanding conditions without succumbing to cracks that could cause catastrophic failures. CUTTING TOOLS FOR HIGH- TEMPERATURE APPLICATIONS Certain advanced ceramics with good fracture toughness can be used as cutting tools for machining high- temperature materials like superalloys or titanium. CUTTING-EDGE AEROSPACE APPLICATIONS Advanced ceramics with exceptional fracture toughness are being explored for use in aerospace components like engine parts and heat shields. JOINT REPLACEMENTS Advanced ceramic materials are being used in artificial joints due to their biocompatibility, good wear resistance and improved fracture toughness compared to traditional materials NUCLEAR WASTE STORAGE Ceramics with high fracture toughness are being investigated for use in nuclear waste storage containers. 12

- 13. STRENGTH OF CERAMICS • Strength is a broad term encompassing a material's ability to withstand various forces without breaking. • It's important to consider different types of strength, such as flexural strength (resistance to bending) and tensile strength (resistance to pulling forces). • The tensile strength as measured in a tensile test is simply the stress P/A at the instant of fracture. The most common experiment is to program a testing machine to increase the displacement (typically for a screw-driven testing machine) or the load (typically for a hydraulic testing machine) at a constant rate. Strength measured in this way at a rapid strain rate is often termed the instantaneous strength. 13 Schematic of tensile test.

- 14. 14 o The relative simplicity of flexural (bend) testing and the low cost of the required specimens have made this test very popular for ceramics despite several drawbacks in interpretation of the resulting data. o These drawbacks include a stress distribution that is both nonuniform and changes with increasing strain if some plastic deformation takes place. o Bars of rectangular or circular cross section are generally used for bend tests on ceramics. o Flexure testing in four-point loading is the most widely used technique for strength measurements of ceramics over the temperature range in which creep is not appreciable. Flexure of a beam Four-point bending FLEXURE TESTS

- 15. FACTORS AFFECTING STRENGTH OF CERAMICS Mineral composition • The inherent strength of the individual minerals used in the ceramic plays a vital role. • Materials with stronger mineral constituents will naturally result in a stronger overall ceramic. Temperature • Strength can be temperature dependent. • Some ceramics might exhibit good strength at room temperature but lose strength at elevated temperatures. Chemical Environment • Exposure to corrosive chemicals can weaken the ceramic over time, affecting its long-term strength. 15

- 16. APPLICATIONS OF STRENGTH OF CERAMICS STRUCTURAL COMPONENTS Ceramics with high flexural strength, or the ability to resist bending forces, are used in building materials like floor tiles, roof tiles, and even some architectural panels. HEAT EXCHANGERS Ceramic heat exchangers, used in various industries, rely on their flexural strength to withstand the pressure differences between hot and cold fluids flowing through them. BUILDING MATERIALS Concrete, a composite material containing ceramic aggregates, utilizes the compressive strength of the ceramic particles to bear the weight of structures. PIPING AND PRESSURE VESSELS Advanced ceramics with good tensile strength are being explored for use in high-pressure applications like piping for chemical processing or pressure vessels for gas storage. DENTAL IMPLANTS AND BONE REPAIR MATERIALS Some ceramics used in dental implants and bone repair materials benefit from good tensile strength to withstand the biting forces in the mouth or the forces experienced during bone healing. 16

- 17. HARDNESS VS FRACTUTRE TOUGHNESS VS STRENGTH OF CERAMICS Hardness Focuses on resistance to permanent indentation or scratching. Higher hardness indicates a material that can better withstand wear and tear on the surface. Think of it as the difficulty of making a mark on the ceramic. Measured using techniques like Vickers hardness test. Fracture Toughness •Focuses on a material's ability to resist crack propagation. •Higher fracture toughness indicates a material that can tolerate existing cracks or flaws without breaking easily. •Think of it as the ceramic's ability to absorb impact or resist a crack from growing into a complete fracture. •Measured using techniques like Single-Edge Precracked Beam (SEPB) or Vickers Indentation Fracture (VIF). 17

- 18. Strength of Ceramics •Broader term encompassing a material's ability to withstand various forces (tension, compression, bending) without breaking. •There are different types of strength, such as flexural strength (resistance to bending) and tensile strength (resistance to pulling forces). •Strength depends on multiple factors, including hardness, fracture toughness, and the specific type of stress applied. •Measured using various techniques depending on the type of strength being evaluated. HARDNESS VS FRACTUTRE TOUGHNESS VS STRENGTH OF CERAMICS 18

- 19. 19 PERFETCT CERAMIC? Hardness: Extremely high. The perfect ceramic should be virtually scratch-proof and resistant to abrasive wear. Imagine a material that can grind other materials without showing any signs of wear itself. Fracture Toughness: Moderately high. While high hardness is crucial, some fracture toughness is still necessary to prevent catastrophic failure from unexpected impacts or internal stresses during grinding operations. Strength: High overall strength, particularly compressive strength to handle the crushing forces involved in grinding. The above mentioned properties may not match. It's important to remember that perfect materials don't exist. However, we can explore ideal properties for hardness, fracture toughness, and strength depending on the desired application:

- 20. SUMMARY • This presentation explored the critical properties that define the performance of ceramics: hardness, fracture toughness, and strength. • Each property plays a vital role, and the ideal combination depends on the specific application. • Understanding these properties allows us to select the right ceramic material for optimal performance. 20

- 21. THANK YOU 21