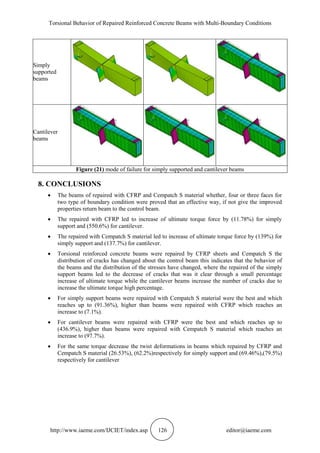

This document presents a study on the torsional behavior of repaired reinforced concrete beams with multi-boundary conditions, utilizing finite element analysis. The research evaluates the effectiveness of two repair techniques—carbon fiber reinforced polymer (CFRP) and high strength concrete (fc85)—in enhancing the torque resistance and reducing twist deformation of beams. Results indicate a significant improvement in performance, particularly with the use of fc85 in simply supported beams, showing remarkable increases in torque capacity and reductions in twist.

![Hayder Al-Khafaji

http://www.iaeme.com/IJCIET/index.asp 113 editor@iaeme.com

High strength concrete was used to repair of all types of structural concrete elements in

buildings, water retaining structures, industrial plants, bridges, etc. where provide high

strength and extremely low shrinkage properties are required.

Externally bonded, CFRP sheets are currently being studied and applied around the world

for the repair and strengthening of structural concrete members [1]. CFRP materials are of

great interest to the civil engineering community because of their superior properties such as

high stiffness and strength has well as ease of installation when compared to other repair

materials.

David, E.,Djelal, C. and Buyle-Bodin , F. [2],using externally CFRP strips to bounded

beams and their results show that CFRP is very effective for flexure strengthening.

S. Panchacharam and A. Belarbi [3], makings experimental study to investigate the

torsional behavior of RC beams strengthened with externally bonded GFRP sheets. The

variables considered in this study are fiber orientation (parallel and perpendicular to the

longitudinal axis of the beam). The torsional reinforced concrete beams strengthened with

GFRP sheets exhibited significant increase in their cracking and ultimate strength as well as

ultimate twist deformations.

R.Dhanaraj and E.Chandrasekaran [4], investigated the numerical study on un retrofitted

and retrofitted reinforced concrete beams subjected to combined bending and torsion by

ANSYS. Then the study has been extended for the same reinforced concrete beams retrofitted

with carbon fiber reinforced plastic composites with ±45° and 0/90° fiber orientations. The

present study reveals that the CFRP composites with ±45° fiber orientations are more

effective in retrofitting the RC beams subjected to combined bending and torsion for higher

torque to moment ratios.

Bonfiglioli et al (2004)[5], carried out an experimental and theoretical study to evaluate

the capability of dynamic testing to give useful information about the stiffness recovery due to

external CFRP strengthening of RC beams which were previously damaged. Specimens were

damaged under cycle loading until cracks appeared. Then CFRP used for repairing cracking

specimens. The theoretical results are in good agreement with the experimental ones. The

research suggests that dynamic testing can be used to obtain useful information about the

effectiveness of the strengthening system.

Ali (2007)[6], casted twenty eight reinforced concrete beams to investigate the behavior of

using CFRP to repaired and strengthened beams failed in flexure and shear zone. All beams

had been tested as a simply supported beam under two point of loading. From the results can

see the use of CFRP as external strengthening has significant effect on ultimate load, crack

pattern and deflection. The repaired beams reach (95% to 97%) of ultimate load in

comparison with those strengthened in the same way by CFRP.

AL-Saidy et al. (2007)[7], studied behavior of corroded damaged reinforced concrete

beams repair/strengthening with CFRP sheets. Ten beams were casted and tested up to failure.

Damaged beams were repaired by bonding CFRP sheets to the tension side to restore the

strength loss due to corrosion. From the results can see The use of CFRP sheets for

strengthening corroded reinforced concrete beams increasing the ultimate strength of repaired

specimens. Deflection was increased for all repaired beams as compared with control beam.

Abed Al-Amery (2009)[8], repaired ten damaged reinforced concrete beams at flexural

region. Steel and CFRP palates used for repairing work to investigate the effect of repairing

materials in restoring the original stiffness and capacity for damage beams. Beams tested as

simply supported beam under two point loading. It was observed that ultimate can be

increased up to (121.4%) in the case of using steel plates. While deflection was decreased to](https://image.slidesharecdn.com/ijciet1001012-190222051546/85/Ijciet-10-01_012-2-320.jpg)

![Torsional Behavior of Repaired Reinforced Concrete Beams with Multi-Boundary Conditions

http://www.iaeme.com/IJCIET/index.asp 114 editor@iaeme.com

(15.4%) times .In case of using CFRP plates, the ultimate can be increased up to (64.3%).

While deflection was decreased to (28.6%) times of the original beams.

Nada S. Assi [9], using finite element method to adopted by ANSYS program for four

beams strengthened in flexure with different length of CFRP sheet to confirm the theoretical

calculations as well as to provide a valuable supplement to the laboratory investigation of

behavior of beams. Good agreement with the experimental test is obtain and this study shows

that the optimum length of CFRP plate equal to 83% of the full span length [10,11].

T.Abdo and R. Mabrouk[12],studied the behavior of simply supported RC beams with

openings subjected to pure torsion then verified using FEM analysis program ANSYS16.

Good agreement between the experimental and numerical results is found. The torque-rotation

relationship for all the beams under study was linear up to the cracking torque and after that it

became nonlinear.

2. MATERIALS CHARACTERISTICS:

The materials of the structural elements that analysis in this study include concrete, steel

reinforcing bars, Cempatch S and CFRP. The finite element models adopted have a number of

parameters, which are summarized in Table (1).

Table (1) Parameters for elements used in F.E. Model for beam

Representation Element Type Characteristics

Concrete Solid65

compressive strength (fc')=30 MPa

Poisson's ratio=0.2

modulus of elasticity=25742 MPa

ultimate strain=0.003

Steel Reinforcement Link180

Ø16, Ø12, Ø10

Yield strength=410 MPa

CFRP Shell41

Cempatch S Solid65

compressive strength (fc')=85 MPa

Poisson's ratio=0.17

modulus of elasticity=43332 MPa

ultimate strain=0.0045

Steel plate Solid185

modulus of elasticity=200000 MPa

Poisson's ratio=0.3

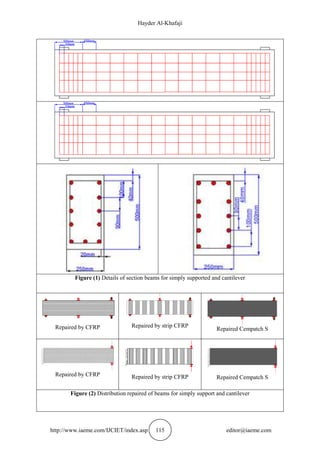

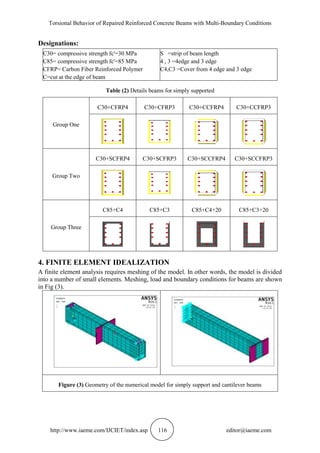

3. NUMERICAL ANALYSIS

The finite elements representation using ANSYS16.1 program has been applied in this study

to know the validate of the numerical representation of the reinforced concrete beams

strengthening with Cempatch S and CFRP subjected to pure torsion. Twenty six reinforced

concrete beams of 500*250 mm cross-section and 2550 mm length were tested in this study

Fig (1). Schematic representations of the repairing and strengthening schemes are shown in

Fig (2) and Table (2) shows the cases of beams.](https://image.slidesharecdn.com/ijciet1001012-190222051546/85/Ijciet-10-01_012-3-320.jpg)

![Hayder Al-Khafaji

http://www.iaeme.com/IJCIET/index.asp 117 editor@iaeme.com

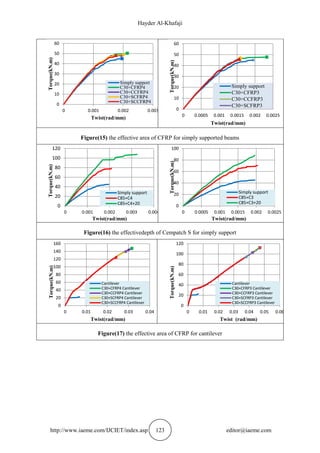

5. RESULTS AND DISCUSSIONS

In this section, the results obtained from ANSYS 16.1 are displayed for 26 beams divided

according boundary condition in two types cantilever and simply support each type include 13

beams. Because there is no experimental program for this research and compare it with the

results of the ANSYS. Therefore, the effectiveness of the program was verified through

another research that contains experimental results [3]. The general behavior of beams of

finite element represented in the torque-twist plots showed good convention with the data of

test from the experimentally tested. The torque-twist curves were show in Fig (4)to(6) and

Table(3).

Designations

A90W4:90 degree complete wrap

A0L4:0 degree, 4 sides

Table (3) Comparison between experimental and numerical ultimate torque and twist

Beam

Ultimate Torque (kN-m) Ultimate Twist (rad/mm)

Experimental Numerical

Percentage

Difference %

Experimental Numerical

Percentage

Difference %

reference 18 19.5 -8.3 110 104 5.45

A90W4 45 48 -6.67 70 63 10

A0L4 29 31.25 -7.76 168 152 9.53

Figure (4) Torque-Twist relationship of reference beam

Figure (5) Torque-Twist relationship of

beam(A90W4)

Figure (6) Torque-Twist relationship of

beam(A0L4)](https://image.slidesharecdn.com/ijciet1001012-190222051546/85/Ijciet-10-01_012-6-320.jpg)

![Hayder Al-Khafaji

http://www.iaeme.com/IJCIET/index.asp 127 editor@iaeme.com

REFERENCES

[1] Meier, U. : "Post-strengthening by continuous fiber sheets in Europe. Proceedings of

Third International Symposium, Non-Metallic (FRP) Reinforcement for Concrete

Structures", Vol. 1, Japan Concrete Institute, Tokyo, pp. 41–56, 1997.

[2] David ,E.,Djelal, C. and Buyle-Bodin , F.: " Repair and Strengthening of Reinforced

Concrete Beams using Composite Materials", second Int. PhD. Symposium in Civil

Engineering, 1998 Budapest, WWW.vbt.bme.hu.

[3] S. Panchacharam and A. Belarbi: "Torsional Behavior of Reinforced Concrete Beams

Strengthened with FRP Composites", First FIB Congress, Osaka, Japan, October 13-

19,2002.

[4] R.Santhakumar R.Dhanaraj and E.Chandrasekaran "Behaviour of retrofitted reinforced

concrete beams under combined bending and torsion".

[5] Bonfiglioli, B., Migo, S., M., Pascale, G., "Dynamic Testing of Reinforced Concrete

Beams Damaged and Repaired with Fiber Reinforced Polymer Sheets", Journal of

materials in civil engineering, ASCE, September 2004.

[6] Ali, D., D., "Experimental and Theoretical Investigation of the Behavior of Reinforced

Concrete Beams Strengthened by Fiber Reinforced Polymer" Ph.D. Thesis, University of

Baghdad, January 2007.

[7] Al-Saidy, A., H., Al-Harthy, A., S., Abdul-Halim, M., Al-Jabri, K., S., Al-shidi, N.,

M.,"Repair Strengthening of Corrosion Damaged Concrete Beams with Fiber Reinforced

Polymers Sheets", University of Patras, Patras, Greece, July 2007.

[8] Abed Al-Amery, S., J., "Behavior of RC Beams Repaired with Steel and CFRP Plates",

M.Sc. Thesis, AI -Mustansiriya University, Iraq, January- 2009.

[9] Nada S. Assi: " The Effect of Carbon Fiber Reinforced Polymer Length on the

Strengthened of Concentrically Loaded Reinforced Concrete Beams : Finite Element

Analysis", Vol. 32, Part (A), No.7, Eng. & Tech. Journal, pp. 1671-1683, 2014.

[10] Kadhim Naief Kadhim and Ghufran A. (The Geotechnical Maps For Gypsum By Using

Gis For Najaf City (Najaf - Iraq) (IJCIET), Volume 7, Issue 44, July-August 2016.

[11] Hassan and Kadhim Naief Kadhim (Development an Equation for Flow over Weirs Using

MNLR and CFD Simulation Approaches). (IJCIET), Volume 9, Issue 3, (Feb 2018)

[12] T. Abdo and R. Mabrouk" Effect of web openings on the structural behavior of RC beams

subjected to pure torsion"](https://image.slidesharecdn.com/ijciet1001012-190222051546/85/Ijciet-10-01_012-16-320.jpg)