This research focuses on retrofitting reinforced concrete (RC) beams using glass fiber reinforced polymer (GFRP) and carbon fiber reinforced polymer (CFRP) sheets to enhance their load-carrying capacity and reduce deflections and crack widths. The study analyzed the flexural behavior of various grades of RC beams retrofitted with different layers of GFRP sheets through experimental tests and finite element modeling using ANSYS software. Results indicated that the use of CFRP and GFRP considerably improved the structural performance of the retrofitted beams compared to control beams.

![International Journal of Trend in Scientific Research and Development @ www.ijtsrd.com eISSN: 2456-6470

@ IJTSRD | Unique Paper ID – IJTSRD52006 | Volume – 6 | Issue – 6 | September-October 2022 Page 1011

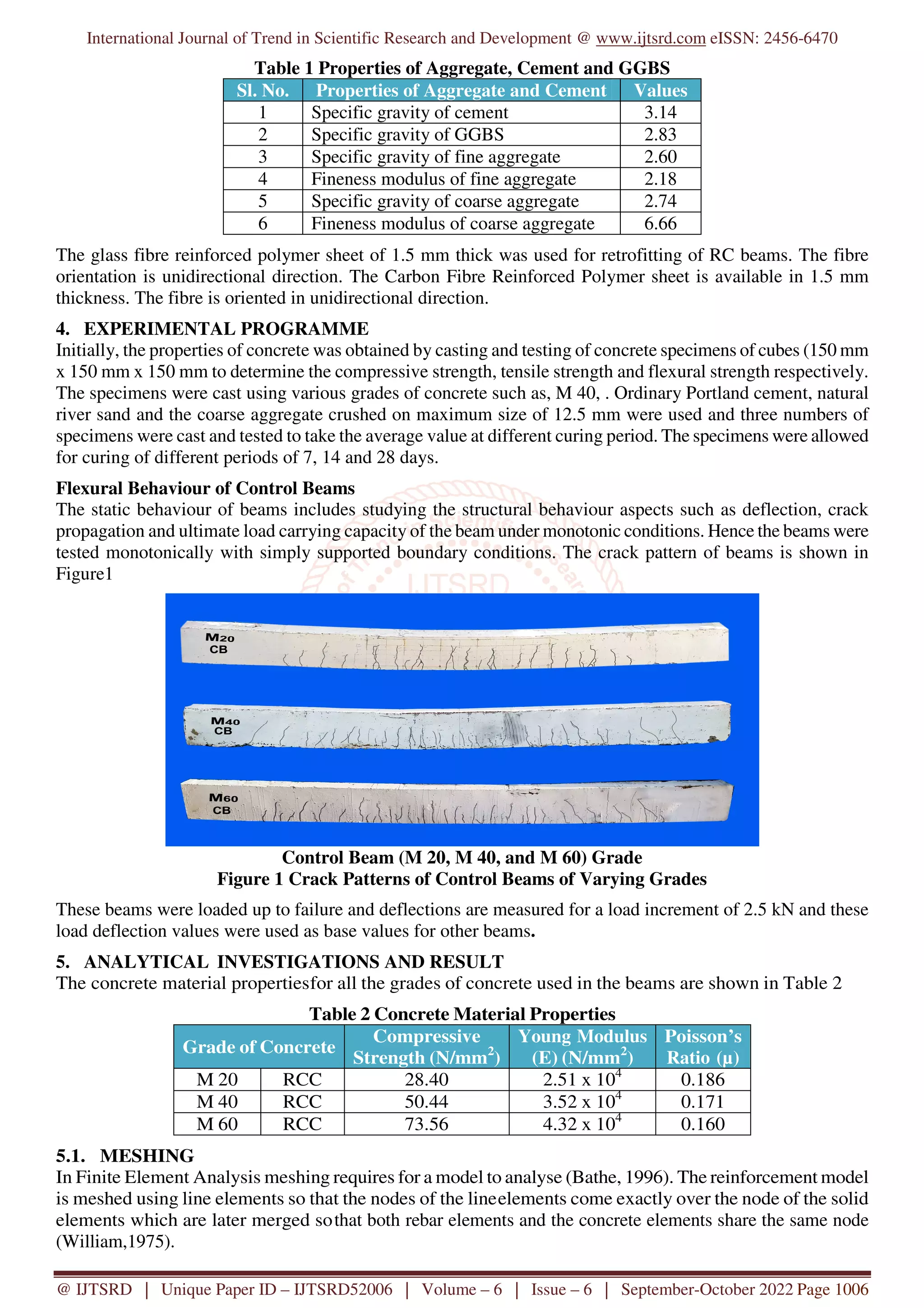

The cracks distribution indicates that the size and

density of crack are lower in the GFRP and CFRP

strengthened beams than in the control beams.

7. REFERENCES

[1] Sharba, Amjad Ali K., Hussain Dhafir

Hussain, and Mohammed Abdulhussain.

"Retrofitting of RC beams using FRP

techniques: a review.” In IOP Conference

Series: Materials Science and Engineering,

vol. 1090, no. 1, p. 012054. IOP Publishing,

2021.

[2] Askar, Mand Kamal, Ali Falyeh Hassan, and

Yaman SS Al-Kamaki. "Flexural and Shear

Strengthening of Reinforced Concrete Beams

Using FRP Composites: A State of The Art.”

Case Studies in Construction Materials

(2022): e01189.

[3] Abbasi, Amirali, Omar Chaallal, and Georges

El-Saikaly. "Shear strengthening of RC

beams with FRP composites: Database of FE

simulations and analysis of studied

parameters.” Modelling and Simulation in

Engineering 2022 (2022).

[4] Panahi, Minoo, Seyed Alireza Zareei, and

Ardavan Izadi. "Flexural strengthening of

reinforced concrete beams through externally

bonded FRP sheets and near surface mounted

FRP bars.” Case Studies in Construction

Materials 15 (2021): e00601.

[5] Rabia, Benferhat, Tahar Hassaine Daouadji,

and Rabahi Abderezak. "Effect of air bubbles

in concrete on the mechanical behavior of

RC beams strengthened in flexion by

externally bonded FRP plates under

uniformly distributed loading.” 1 3, no. 1

(2021): 41.

[6] ACI Committee 440 Report, “Guide for the

design and construction of externally bonded

FRP systems strengthening concrete

structures”, (Revised 24 May 2000).

American Concrete Institute, Farming Hills,

Michigan, 2000, 1-89.

[7] ACI Committee 440. 2 R-02 (2002), Guide

for the design and construction of externally

bonded FRP systems for strengthening

concrete structures.

[8] Aiello. M. A., and Ombres. L., (2004),

Cracking and deformability analysis of

reinforced concrete beams strengthened with

externally bonded carbon fiber reinforced

polymer sheets, Journal of Material in Civil

Engineering, 16(5), 392-399.

[9] Alagusundaramoorthy. P., Harik. I. E., M.

ASCE., and Choo. C. C., (2003), Flexural

behavior of RC beams strengthened with

carbon fiber reinforced polymer sheets of

fabric, Journal of Composites for

Construction, 7(4), 292-301.

[10] Ali, Abdel-Zaher and Ambalavanan, R.,

(1998), Development and behavior of repair

mortars for RC components, The Indian

Concrete Journal, 669-675.

[11] ANSYS, (2003), The general purpose finite

element software, version 8. 0, Swanson

Analysis systems, Inc., International

Houston, TX, USA.

[12] Anwar, A. W., Nimityongskul, P., Pama, R.

P., and Austriaco, L., (1991), Method of

rehabilitation of structural beams elements

using ferrocement, Journal of Ferrocement,

21(3), 229-234.

[13] Daniel, Isaac M., Ori Ishai, Issac M. Daniel,

and Ishai Daniel. Engineering mechanics of

composite materials. Vol. 1994. New York:

Oxford university press, 2006.

[14] Åström, B. Tomas. Manufacturing of polymer

composites. Routledge, 2018.](https://image.slidesharecdn.com/119reinforcementofreinforcedconcretebeamsusingcfrpandgfrp-221108053302-a7f55538/75/Reinforcement-of-Reinforced-Concrete-Beams-using-CFRP-and-GFRP-8-2048.jpg)