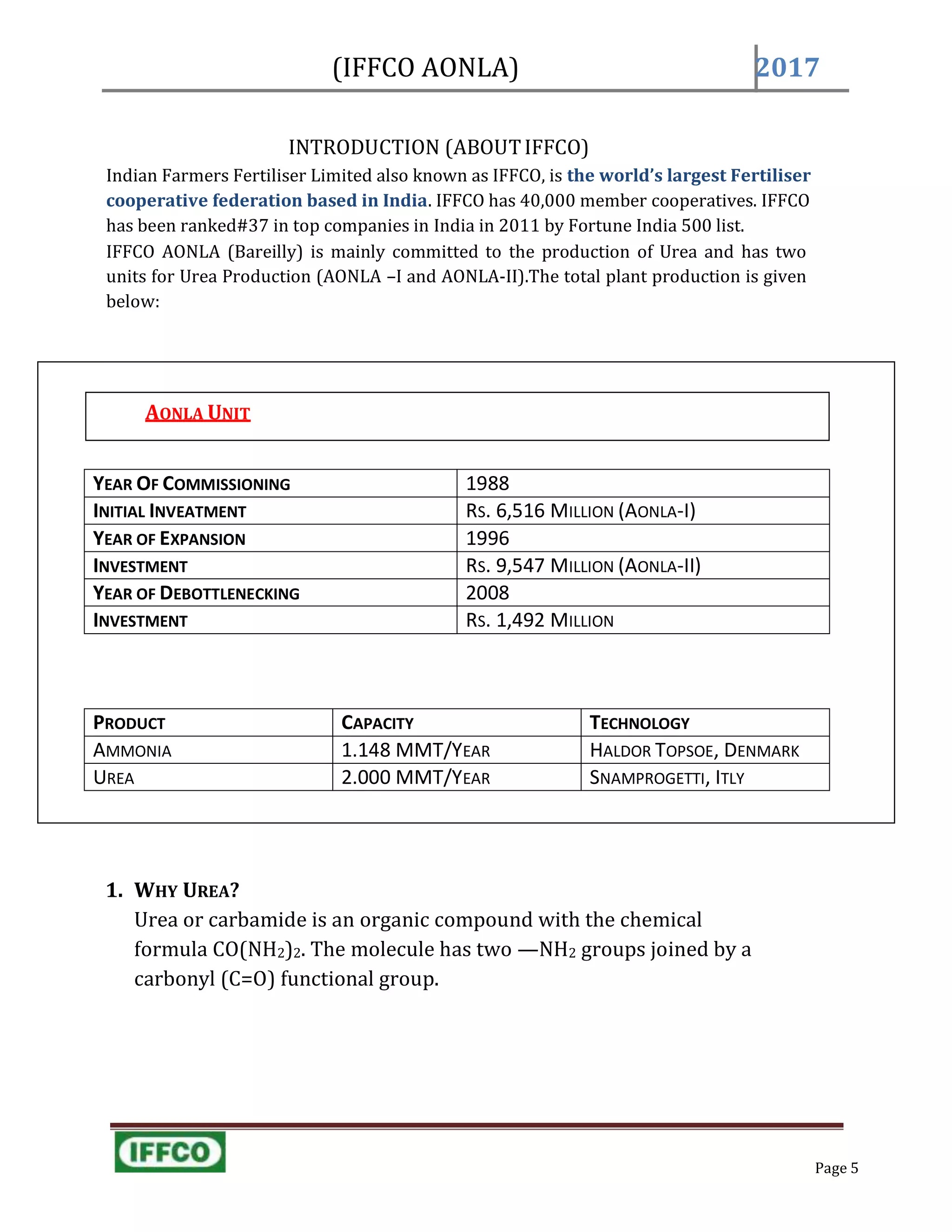

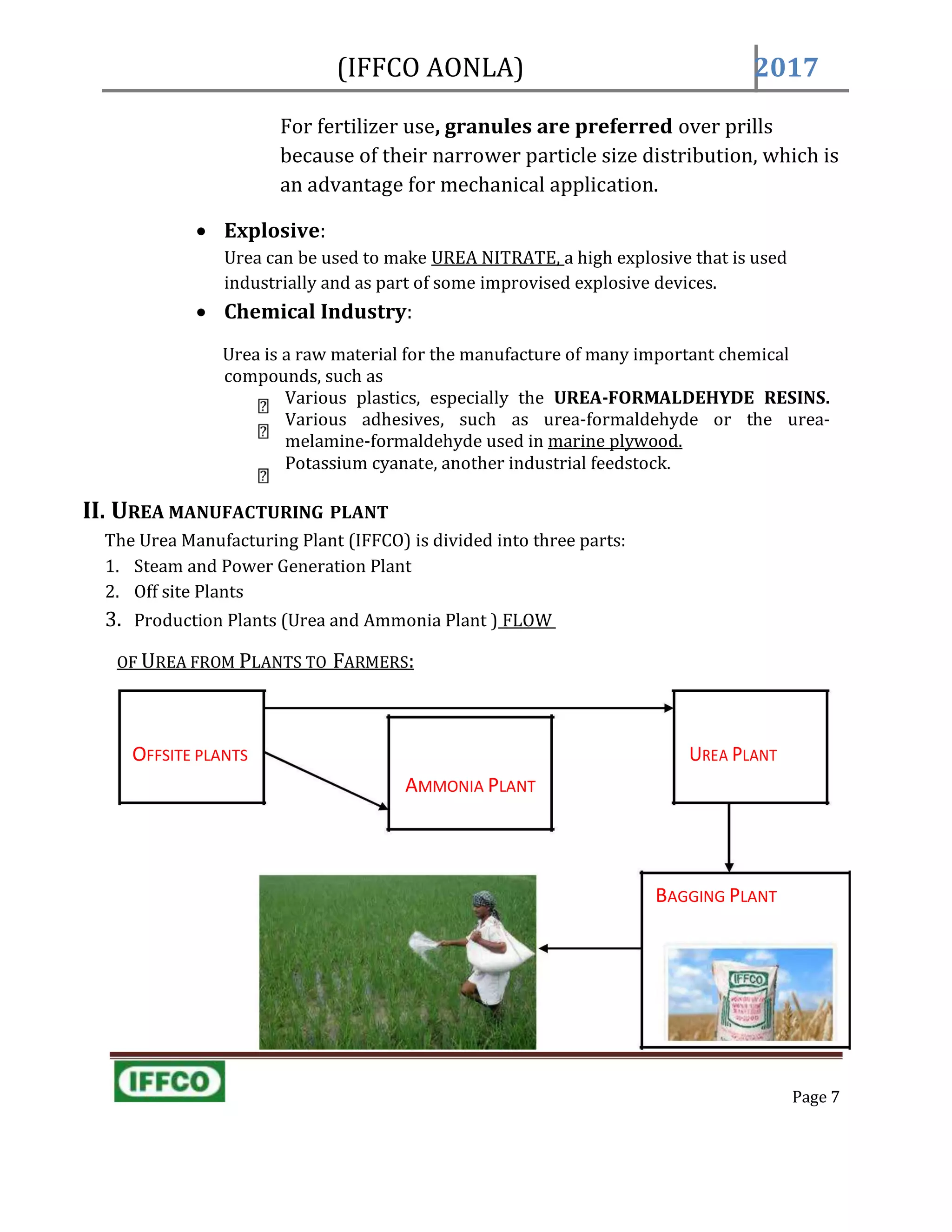

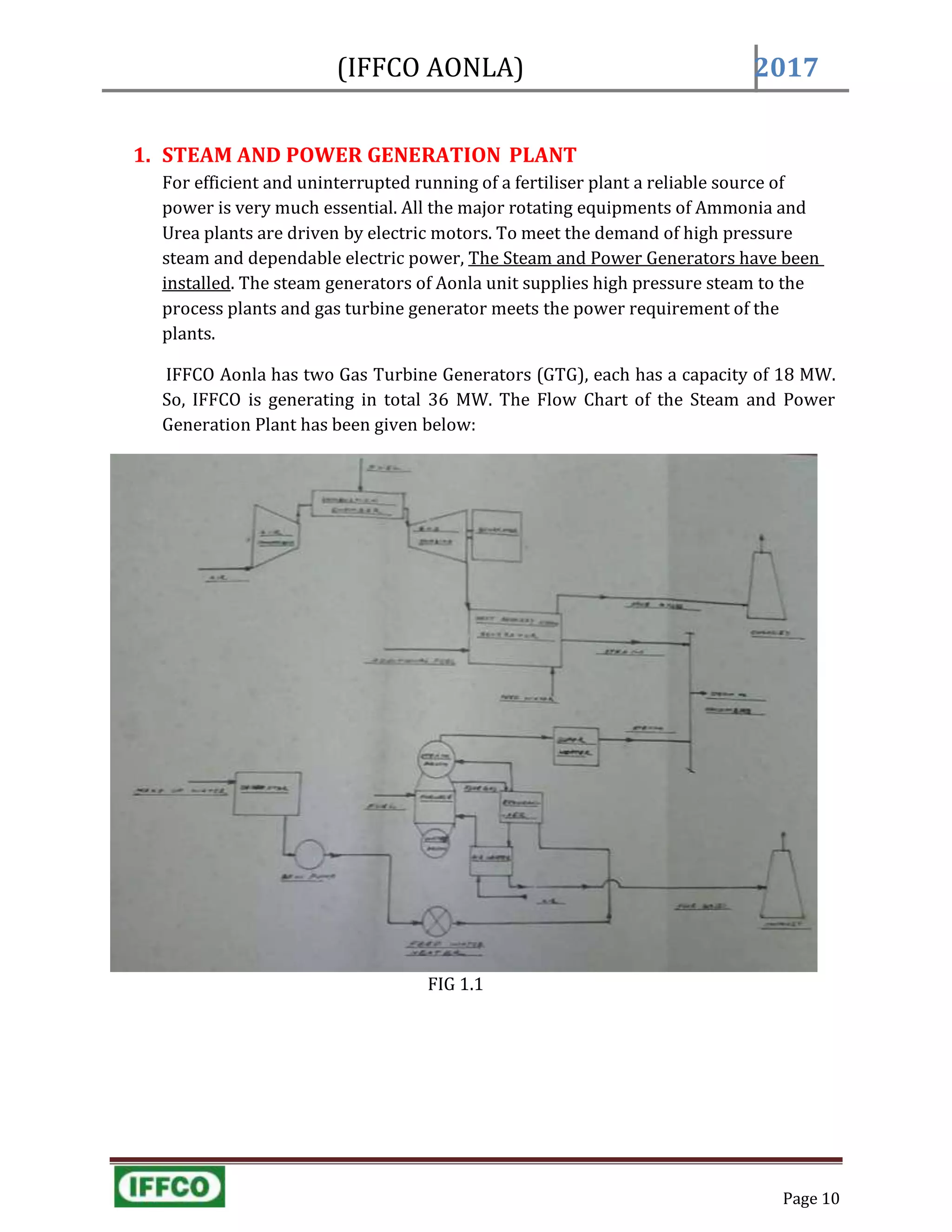

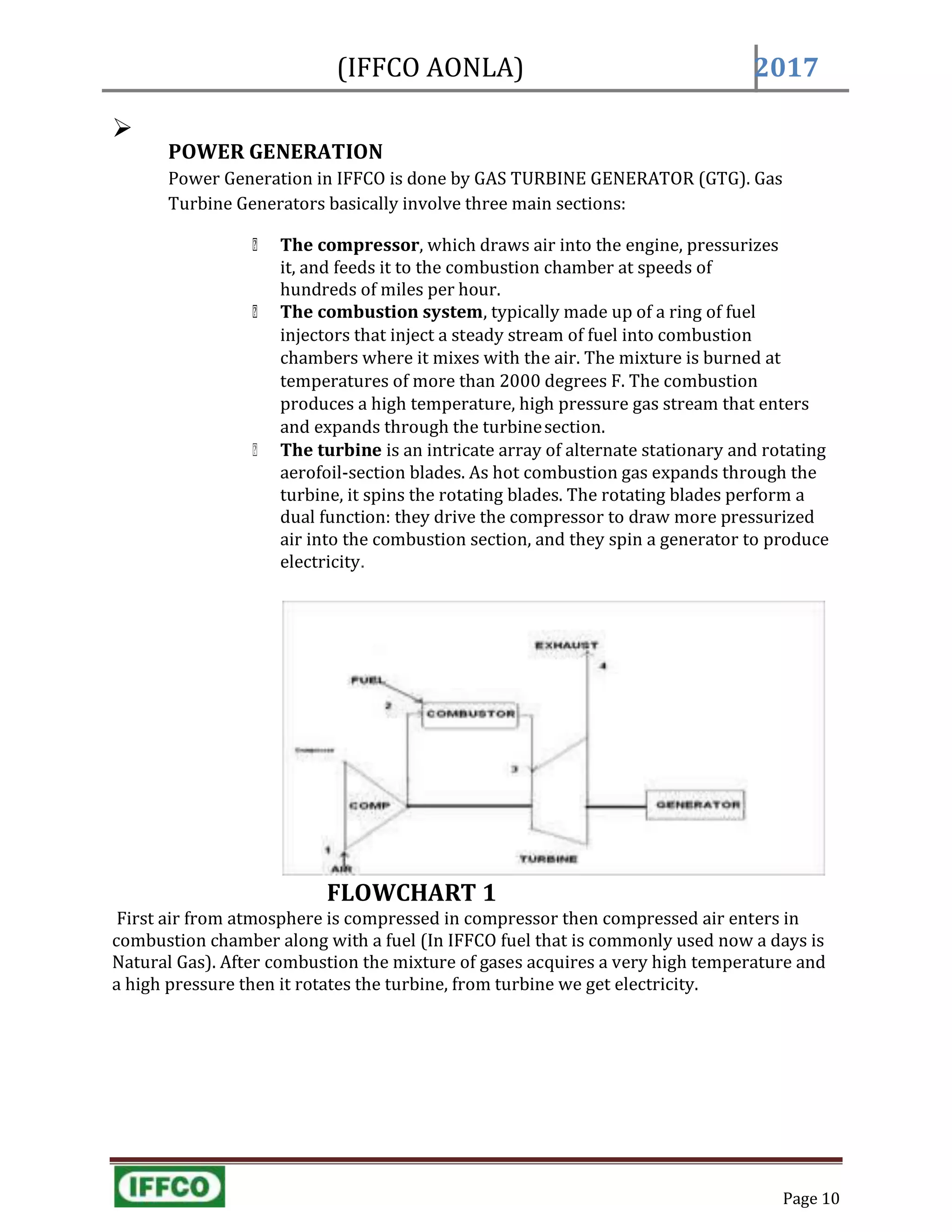

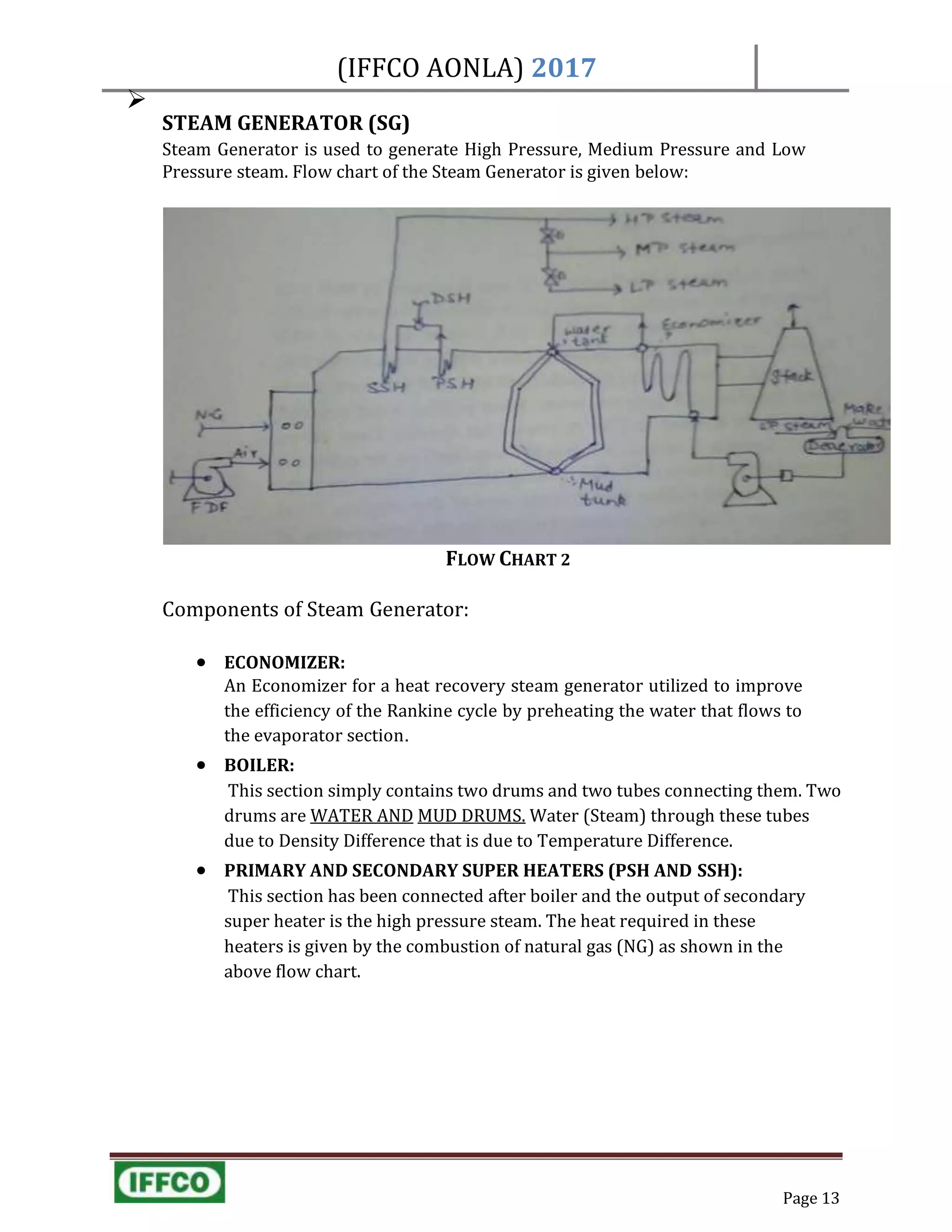

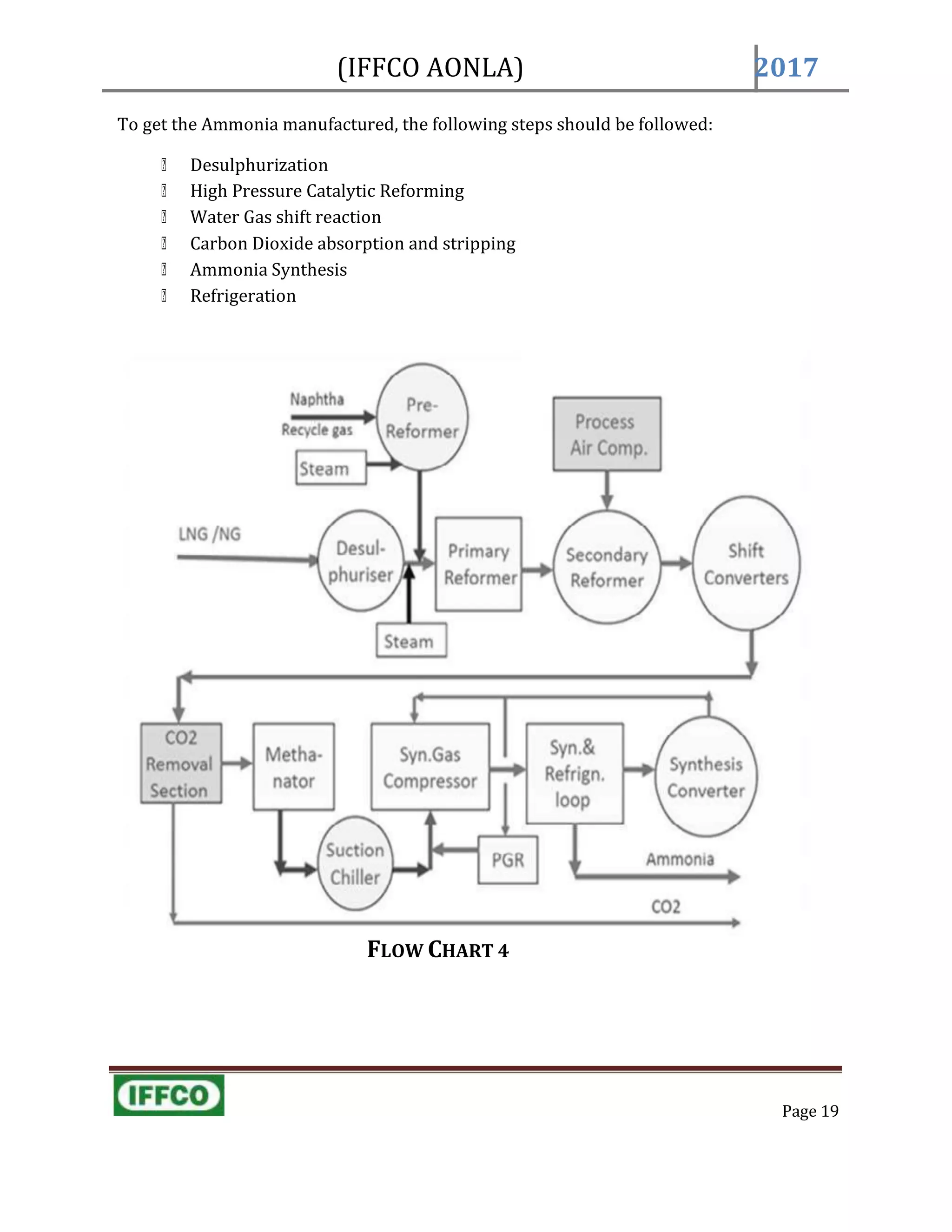

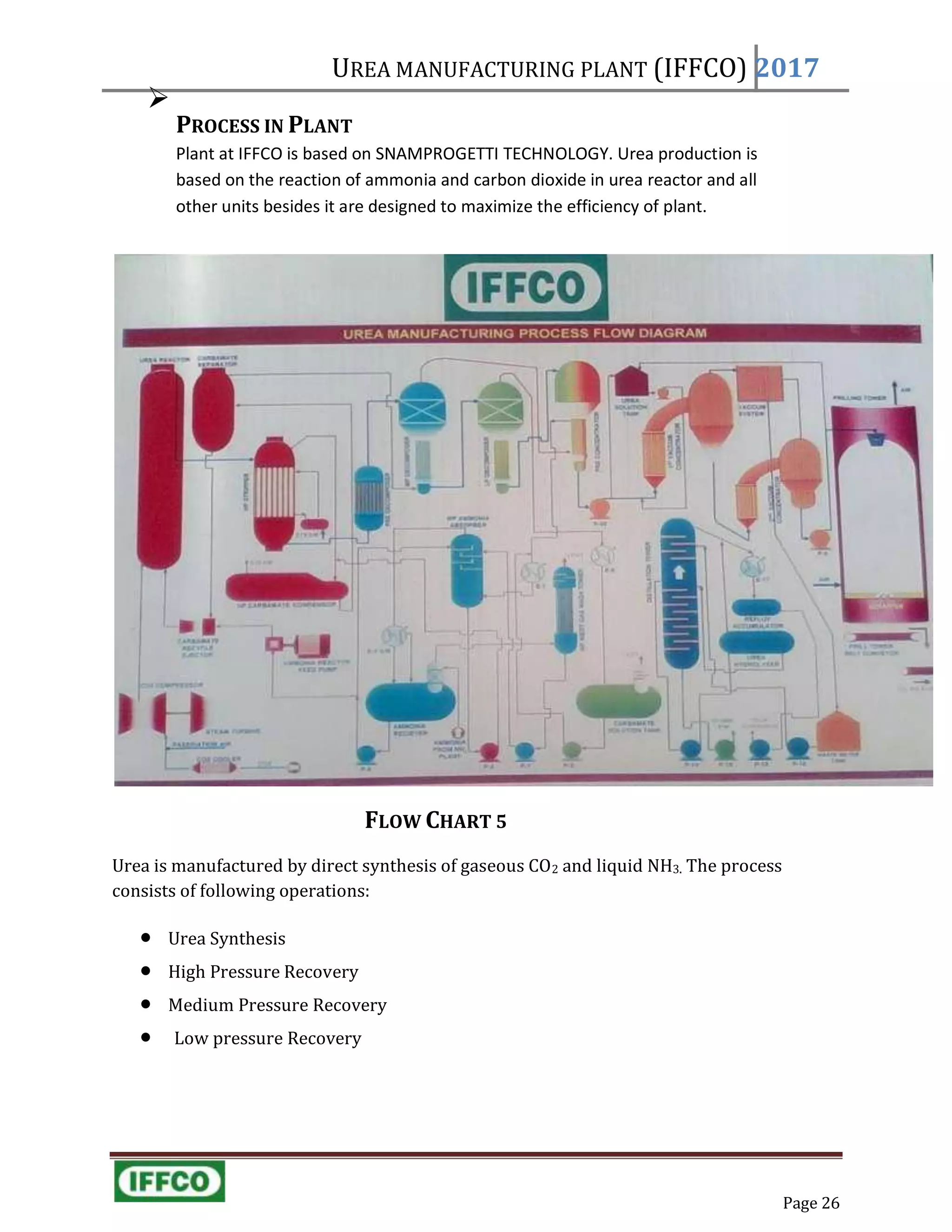

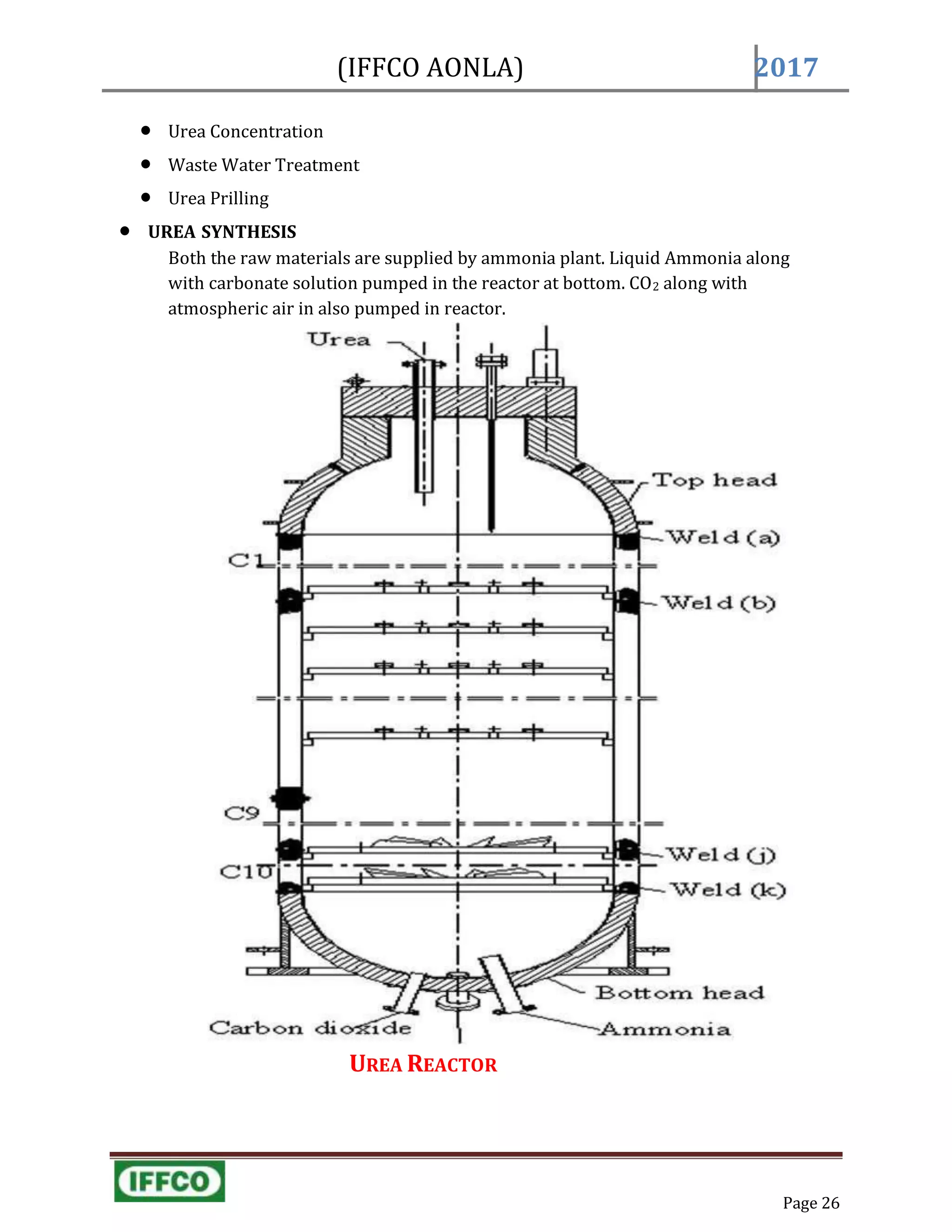

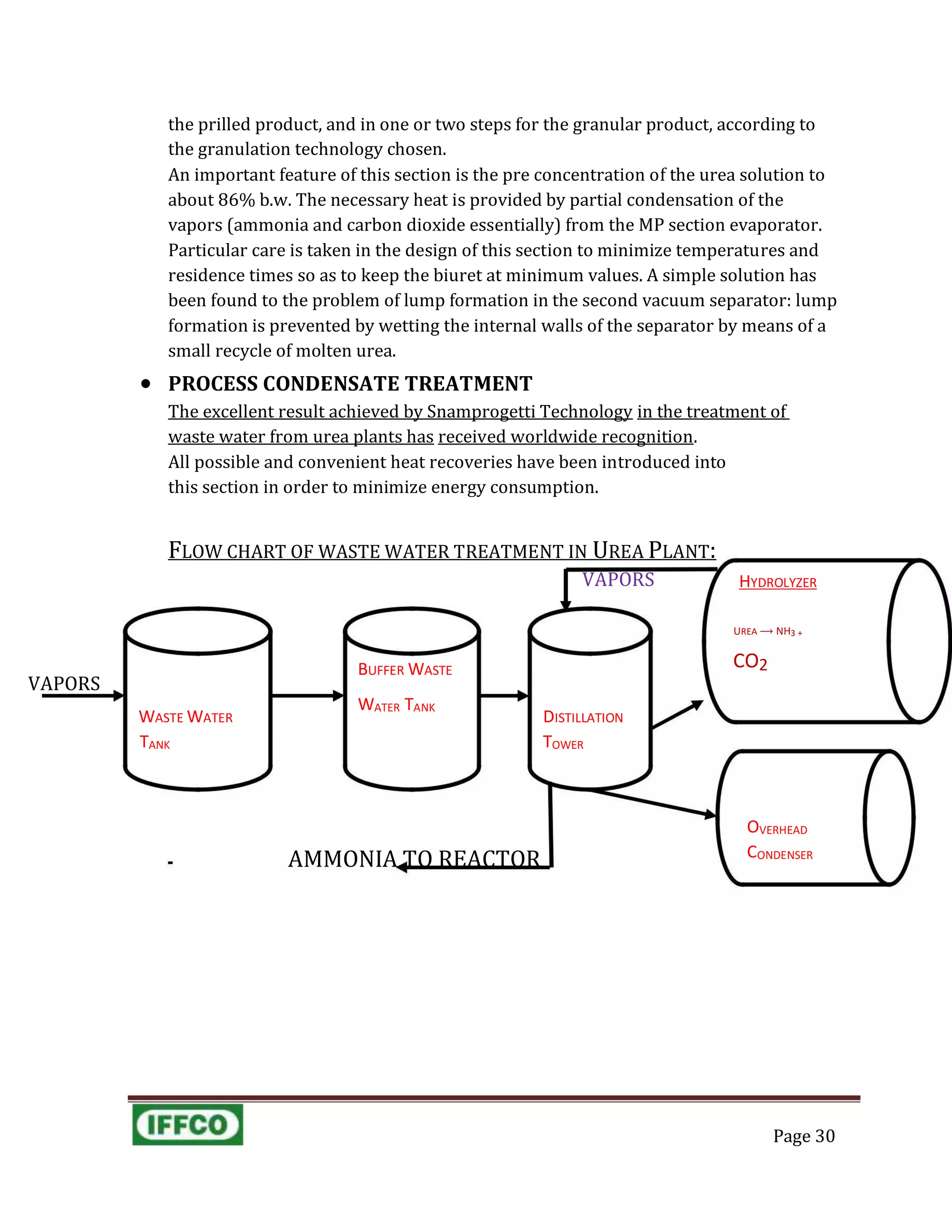

This document provides a training report submitted by Arif Khan to Mr. Rohit Pal regarding Arif's 6-week vocational training at the IFFCO Urea Manufacturing Plant in Aonla, India. The report includes an abstract describing IFFCO as an organization and details about the Aonla plant. It then covers various sections of the plant including steam and power generation, naptha storage, offsite plants like water treatment and cooling towers, the ammonia and urea production plants, and safety practices.