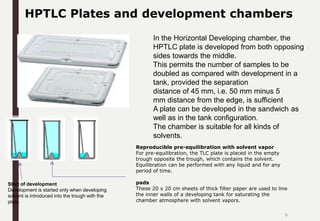

This document discusses the process of HPTLC development and evaluation. It describes how placing an HPTLC plate in a saturated developing chamber results in four competing processes: 1) establishment of vapor phase equilibrium, 2) adsorption of gas phase molecules onto the stationary phase, 3) interaction of wetted layer with gas phase, and 4) separation of mobile phase components by the stationary phase. It also explains how chamber saturation, preconditioning, and sandwich configurations can affect these processes and the resulting chromatogram. Quantitative evaluation is performed through densitometric analysis and comparison of peak data from unknown samples to calibration standards run on the same plate.