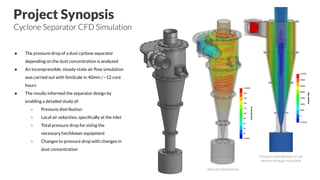

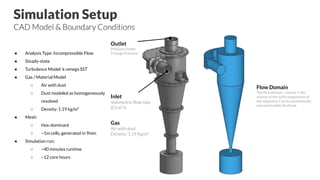

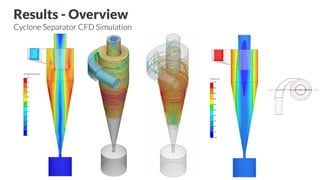

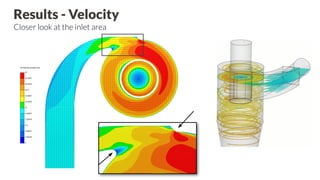

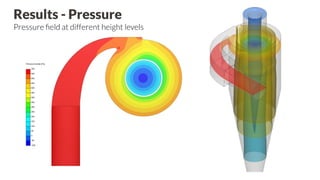

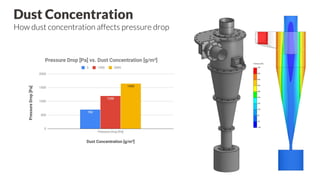

The document summarizes a CFD simulation of a cyclone separator that analyzed how the pressure drop is affected by dust concentration. A steady-state simulation was run in 40 minutes using 12 CPU cores. The results provided insight into the pressure distribution, air velocities at the inlet, total pressure drop for sizing equipment, and how pressure drop changes with dust concentration.