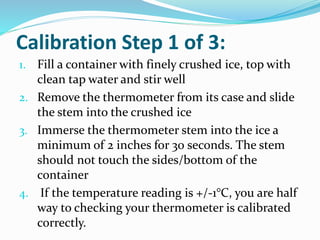

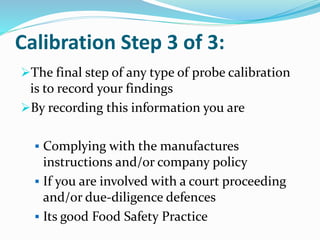

This document provides instructions for calibrating thermometers in the food industry. It states that thermometers should be calibrated for manufacturer recommendations, for legal reasons if involved in court proceedings, as a food safety practice, and to ensure due diligence. It demonstrates how to calibrate a probe thermometer using ice water and boiling water, and the steps to record the calibration for compliance. The document also identifies different types of thermometers and what to do if a thermometer is not working correctly, such as checking batteries, wires, and displays, or sending for manufacturer calibration.