Embed presentation

Downloaded 26 times

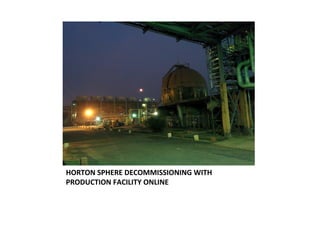

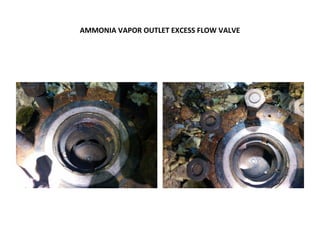

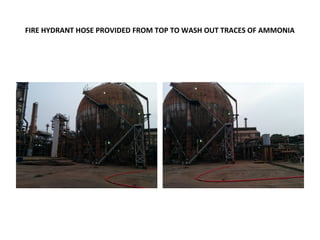

The document describes the decommissioning of a Horton sphere production facility. Key steps included emptying the sphere of ammonia and water, purging it with an inert gas, blinding open ends, draining water used to wash the ammonia-rich atmosphere, creating ventilation for inspection, dropping a level indicator for servicing, overhauling a refrigeration compressor, using a fire hydrant to wash out ammonia traces, arranging tankers for emergencies, testing connected lines for thickness and strength, removing and boxing insulation, arranging a hydrotest, replacing isolation and ESD valves, and isolating and purging ammonia submerged pumps for servicing.