This presentation summarizes Heavy Engineering Corporation Ltd (HEC), which has three main manufacturing plants:

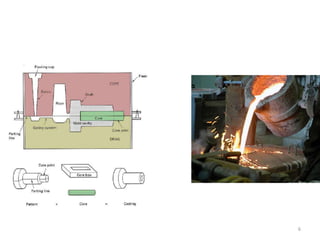

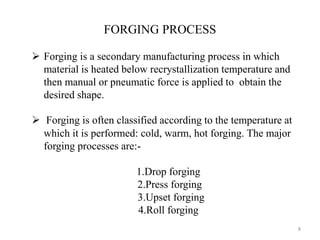

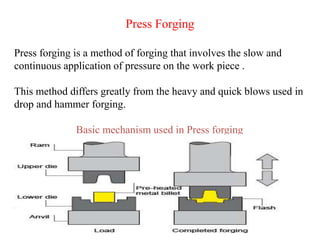

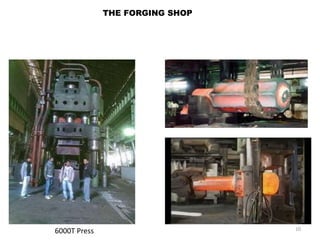

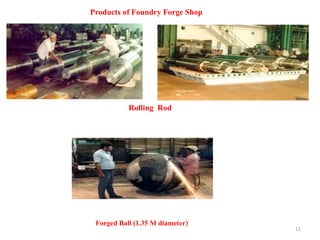

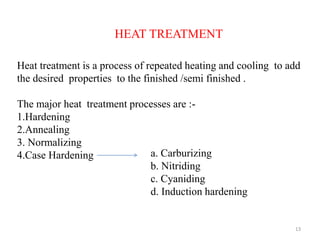

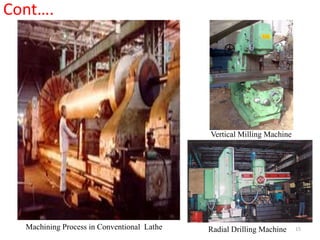

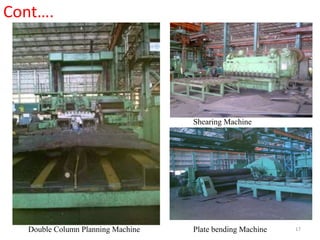

1. The Foundry Forge Plant is the largest foundry and forging complex in India. It produces cast and forged iron and steel products weighing up to 70 tons using processes like casting, forging, heat treatment, and machining.

2. The Heavy Machine Building Plant designs and manufactures heavy machinery for industries like steel, mining, cement, and nuclear power. It is equipped with machine tools to produce components through machining processes.

3. The Heavy Machine Tools Plant manufactures medium and heavy-duty CNC and conventional machine tools for sectors like railways, defense, and space.