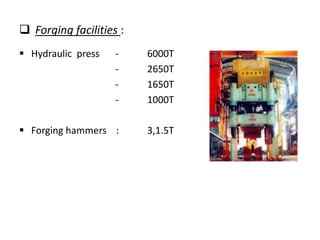

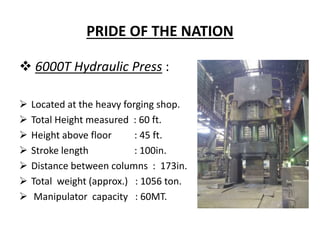

The document summarizes an industrial training at Heavy Engineering Corporation Ltd (HEC) in Ranchi, Jharkhand, India. HEC has three main manufacturing units: a Foundry Forge Plant that produces castings and forgings, a Heavy Machine Building Plant that manufactures equipment for steel plants and other industries, and a Heavy Machine Tools Plant that designs machine tools. The training covered tours of each plant and their manufacturing capabilities. Key equipment seen included a 6000-ton hydraulic press and large lathes and boring mills. HEC produces products like electric overhead cranes, mining shovels, and specialized machine tools.