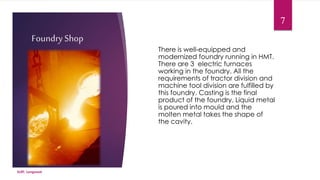

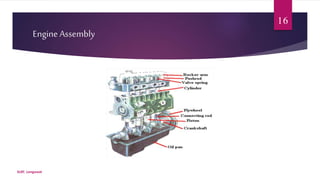

HMT Ltd. Pinjore is a machine tool manufacturing company located in Pinjore, India. It was established in 1963 and produces milling machines. The presentation discusses the various production processes at HMT Pinjore, including the pattern shop, foundry, heat treatment, machine shop, engine assembly, testing, and tractor assembly. Key parts of the engine like the crankcase, cylinder, piston, connecting rod, and crankshaft are machined at HMT. Finally, HMT produces several models of tractors.