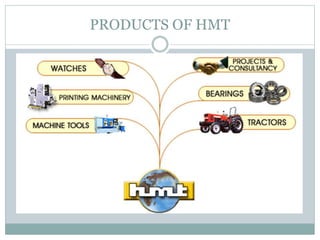

This document provides an overview of HMT Limited, an Indian manufacturing company established in 1953. It details the company's 18 production plants across India and the Ajmer unit's establishment in 1967 in collaboration with foreign partners. The document then describes the various departments within the Ajmer unit, including foundry, manufacturing, inspection, assembly, and maintenance. It provides examples of machines and processes within departments like tool room, heavy duty machining shop, and grinding. In conclusion, it calls for measures to reduce costs and prices to make HMT more competitive.