Recrystallization annealing of steels for microstructure control

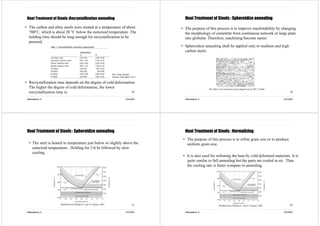

- 1. Heat Treatment of Steels :Recrystallization annealing • The carbon and alloy steels were treated at a temperature of about 700°C, which is about 20 °C below the eutectoid temperature. The holding time should be long enough for recrystallization to be proceed. • Recrystallization time depends on the degree of cold deformation. The higher the degree of cold deformation, the lower recrystallization time is. Ref: Linde booklet: Furnace Atmosphere No.2 3/21/2012Kitkamhorn, U. 29 Heat Treatment of Steels : Spheroidize annealing • The purpose of this process is to improve machinability by changing the morphology of cementite from continuous network or large plate into globular. Therefore, machining become easier. • Spheroidize annealing shall be applied only to medium and high carbon steels. 3/21/2012Kitkamhorn, U. Ref: http://www.astonmet.com/ss/images/win_ht1207_23.html 30 Heat Treatment of Steels : Spheroidize annealing • The steel is heated to temperature just below or slightly above the eutectoid temperature. Holding for 2-6 hr followed by slow cooling 3/21/2012Kitkamhorn, U. Modified from William D., and Jr. Callister, 2007 31 Heat Treatment of Steels : Normalizing • The purpose of this process is to refine grain size or to produce uniform grain size. • It is also used for softening the heavily cold deformed materials. It is quite similar to full annealing but the parts are cooled in air. Thus the cooling rate is faster compare to annealing. 3/21/2012Kitkamhorn, U. Modified from William D., and Jr. Callister, 2007 32

- 2. Heat Treatment of Steels : Normalizing • Normalizing is considered to be out of equilibrium since the air-cooling is considerably fast. • Eutectoid temperature and composition become lower as cooling rate increase. • Ar3 and Ar1 merge and full pearlitic microstructure is obtained in steels with >0.4%C 3/21/2012Kitkamhorn, U. A1 Acm A3 Modified from William D., and Jr. Callister, 2007 33 Heat Treatment of Steels : Quenching and Tempering • The purpose of quenching and tempering is to improve hardness, strength, and wear resistance of the parts. • The desired microstructure is martensite or bainite or mixture of both depending on the hardness, strength, and toughness required in service. 3/21/2012Kitkamhorn, U. [Ref: Heat Treater’s Guide, 1995]34 Heat Treatment of Steels : Quenching and Tempering • The hardness of martensite is a function of carbon contents only. • The maximum hardness (fully matensite) is then a function of carbon contents in steels. Ref: Linde booklet: Furnace Atmosphere No.2 3/21/2012 This point is important for materials selection Kitkamhorn, U. 35 Heat Treatment of Steels : Quenching and Tempering • The steel parts are heated to a temperature above A3 for hypoeutectoid steel and above A1 for hypereutectoid steel. • Soaking time is about 30 minutes per 1 inch cross section. • The parts are rapidly cooled (so called “quench) in either brine, water, hot oil, cold oil, forced air, and still air. temperature time austenitizing quenching tempering 3/21/2012Kitkamhorn, U. Modified from William D., and Jr. Callister, 2007 36

- 3. Heat Treatment of Steels : TTT and CCT Metallurgists use TTT and CCT diagrams to design the quenching severity required to achieve the target hardness value. TTT (time-temperature transformation diagram) indicates the isothermal transformation versus holding time. CCT (continuous cooling transformation diagram) indicates the transformation by the different cooling rate. 3/21/2012Kitkamhorn, U. 37 Heat Treatment of Steels : TTT diagram Ref: William D., and Jr. Callister, 2007 3/21/2012Kitkamhorn, U. 38 3/21/2012Kitkamhorn, U. Heat Treatment of Steels : TTT diagram Modified from William D., and Jr. Callister, 2007 39 Heat Treatment of Steels : TTT diagram Curves on TTT • Upper curves are of diffusion transformation e.g. • γ→ α +γ • γ→ Fe3C +γ • γ→ α +Fe3C • Lower curve are of bainitic transformation • Horizontal lines are of martensitic transformation 3/21/2012Kitkamhorn, U. 40

- 4. Heat Treatment of Steels : TTT diagram 3/21/2012Kitkamhorn, U. 41 Heat Treatment of Steels : TTT diagram 3/21/2012Kitkamhorn, U. 42 Heat Treatment of Steels : TTT diagram TTT diagram of AISI 4340 steel (JIS-SNCM 439, DIN 20CrMo5) (0.4%C, 1.0%Mn, 0.8%Cr, 0.8%Mo, 1.85%Ni) Ref: William D., and Jr. Callister 3/21/2012Kitkamhorn, U. Additions of alloying elements result in • Separation of diffusion transformation and bainitic transformation curves. • The position of the nose of diffusion transformation curve (upper curves). • The position of the nose of bainitic transformation curve • The position of Ms. 43 Heat Treatment of Steels : TTT diagram Important information of TTT needed to be considered • The position of the nose which indicates the critical cooling rate to suppress diffusion transformation • Ms temperature indicating that austenite start to transform into martensite at such temperature. • Fraction of martensite at a temperature below Ms. This indicates that after quenching to room temperature, how much retained austenite exist in the steel. Modified from William D., and Jr. Callister, 2007 3/21/2012Kitkamhorn, U. 44

- 5. Heat Treatment of Steels : CCT diagram Modified from William D., and Jr. Callister, 2007 3/21/2012Kitkamhorn, U. 45 Heat Treatment of Steels : CCT diagram • CCT curves are slightly on the lower right of TTT curves • Better to follow CCT since most heat treatment processes are based on continuous cooling except martempering and austempering. Ref: William D., and Jr. Callister, 2007 3/21/2012Kitkamhorn, U. 46 Heat Treatment of Steels : CCT diagram TTT and CCT Diagram of AISI 4340 steel (0.4%C, 1.0%Mn, 0.8%Cr, 0.8%Mo, 1.85%Ni) Ref: William D., and Jr. Callister, 2007 3/21/2012Kitkamhorn, U. 47 Heat Treatment of Steels : How to read CCT 3/21/2012Kitkamhorn, U. Hardness %bainite %proeutectoid ferrite %pearlite 48

- 6. Heat Treatment of Steels : Quenching and Tempering • Alloying elements except cobalt shift TTT to the right. • This increases hardenability of the steels. Ac1 Ac3 F+C F+CA+F+C A+F+C A Ms ½” 1” 2” Temperature Time HRC Distance from specimen core Critical cooling rate Ac1 Ac3 F+C F+CA+F+C A+F+C A 1”½” 2” Ms Temperature Time HRC Distance from specimen core Critical cooling rate 3/21/2012Kitkamhorn, U. 49 Heat Treatment of Steels : Quenching and Tempering • The hardenability of high alloy steels is much better than that of carbon steels. • Air-cooling is fast enough to quench the high alloy steel. • Alloying elements also decrease Ms and Mf. • Carbon strongly influences Ms • In alloy steels with >0.4%C, some retained austenite exists after quenching. Ref: Linde booklet: Furnace Atmosphere No.2 3/21/2012Kitkamhorn, U. 50 Heat Treatment of Steels : Quenching and Tempering • As-quenched martensite is brittle because of strain accompanied with phase transformation. • There is a volume expansion when austenite transforms into martensite. • Tempering is a process used for stress-relieving of fresh martensite by heating to a temperature at a range of 150-650°C for 40-60 minutes or longer. 3/21/2012Kitkamhorn, U. 51 Heat Treatment of Steels : Quenching and Tempering • At high temperature Some carbon atoms are rejected from martensite and form carbide. The BCT- martensite become closer to BCC-ferrite and the hardness decreases. • Retained austenite can also decompose into ferrite and carbide. • These phenomena are also accompanied with the volume change. 3/21/2012Kitkamhorn, U. Ref:[Heat Treater’s Guide] 52

- 7. Heat Treatment of Steels : Quenching and Tempering • Tool steels such as hot-work tool steels, cold-work tool steels, and high speed tool steels, the tempering curves exhibit secondary hardening at tempering temperatures in a range of 450-600°C. • Such steels need to be tempered twice or more. Carbon steels Low to medium alloy steels high alloy steels with high carbon contents high alloy steels with medium carbon contents Ref: George E. Totten 3/21/2012Kitkamhorn, U. Heat Treatment of Steels : Quenching and Tempering 3/21/2012Kitkamhorn, U. 54 Heat Treatment of Steels : Quenching and Tempering • Sub-zero quenching is an option treatment for high alloy steel quenching. • The purpose of this method is to remove the retained austenite. • After oil or air quenching to room temperature, the parts are dipped into cryogenic media such as liquid nitrogen. • The parts are then tempered afterward. temperature time austenitizing quenching tempering Sub-zero quenching 3/21/2012Kitkamhorn, U. 55 Heat Treatment of Steels : Martempering • The transformation of austenite into pearlite or bainite is delayed by addition of some alloying elements. • The high alloy steels can be isothermal holding at a temperature above Ms for long time without undergoing phase transformation • Large or complex high alloy steel parts can then be treated by martempering to avoid quench- cracking temperature time austenitizing tempering 3/21/2012Kitkamhorn, U. 56

- 8. Heat Treatment of Steels : Martempering martemperingquenching 3/21/2012Kitkamhorn, U. 57 Heat Treatment of Steels : Austempering temperature time austenitizing• Austempering produces bainite microstructure by quenching to the temperature above Ms and isothermally holding until the bainitic transformation is completed. • The austempered steel exhibit high strength, high tougness, and high ductility. • Coil spring and disc spring are examples of steel parts treated by austempered Ref: George E. Totten, 2006 3/21/2012Kitkamhorn, U. 58 Heat Treatment of Steels : Austempering - Not all steels can be austempered practically. - Their kinetics of bainitic transformation determined whether austempering shall be applied to such steels. Ref: George E. Totten, 2006 3/21/2012Kitkamhorn, U. 59 Heat Treatment of Steels : Summary of Metallurgical Factors during heat treatment 3/21/2012Kitkamhorn, U. Understand the concept of microstructural change due to thermal treatment Case 1 When crystallization of austenite and its transformation are the principles behind then what needed to be considered • Austenitizing temperature must be proper selected depending on the chemical compositions of steels, the methods of cooling, and the final microstructure required. • When austenitizing treatment is in the single austenite region such as hardening of medium carbon steels, treatment temperature and time should not be too high since austenite grain coarsening may occur. • Proper cooling rate (quenching method) is required. • The final microstructure required • There is a limitationof miximum hardness of steel, which can be reached depending on the carbon conceration 60

- 9. 3/21/2012Kitkamhorn, U. Case 2 When recrystallization of the same phase (α in α) is the principle behind • Treatment temperature must be high enough to drive nucleation of new strain-free grains. • Proper time is required but too long time has no benefit or may cause to large grain size. • Only heavily cold-worked low carbon steels are treated with this method since large cold deformation is required as a drivig force for necleation. 61 Heat Treatment of Steels : Summary of Metallurgical Factors during heat treatment Heat Treatment of Steels : External Factors during heat treatment 3/21/2012Kitkamhorn, U. • Oxidation • Discoloration • Carburization/decarburization • Effectiveness of quenchant • Stability of quechant temperature and its thermo-physical properties • Transport of heat into/out of steel parts • Parts configuration • Jig Design • etc 62 References: • George E. Totten. Steel Heat Treatment Handbook : Metallurgy and Technologies, CRC Press, USA 2006 • George Krauss. S T E E L S :Processing, Structure, and Performance . ASM International, USA 2005 • Heat Treater’s Guide: Practice and Procedure for Iron and Steel. ASM International 2nd edition, USA 1995 • H. Eallentowitz et al. “Materials for future automotive body structure” Business Briefing:GlobalAutomotive Manufacturing & Technology 2003 • Karen Connery and Len Switzer. “High Quality Heat Treatment: Atmosphere choice of critical” Heat Treating Progress, September 2008 • Linde booklet: Furnace Atmosphere No.1 Gas carburizing and carbonitriding. Special Edition available from http://heattreatment.linde.com/international/web/lg/ht/like35lght.nsf/docbyalias/homepage • Linde booklet: Furnace Atmosphere No.2 Neutral hardening and annealing. Special Edition available from http://heattreatment.linde.com/international/web/lg/ht/like35lght.nsf/docbyalias/homepage • Linde booklet: Furnace Atmosphere No.3 Nitriding and nitocarburizing. Special Edition available from http://heattreatment.linde.com/international/web/lg/ht/like35lght.nsf/docbyalias/homepage • William D., and Jr. Callister MATERIALS SCIENCE AND ENGINEERING: AN INTRODUCTION John Wiley & Sons, 7th 2007 • Dissemination of IT for the Promotion of Materials Science (DoITPoMS), Universiy of Cambridge, http://www.doitpoms.ac.uk/about/dissemination.html 3/21/2012Kitkamhorn, U. 63