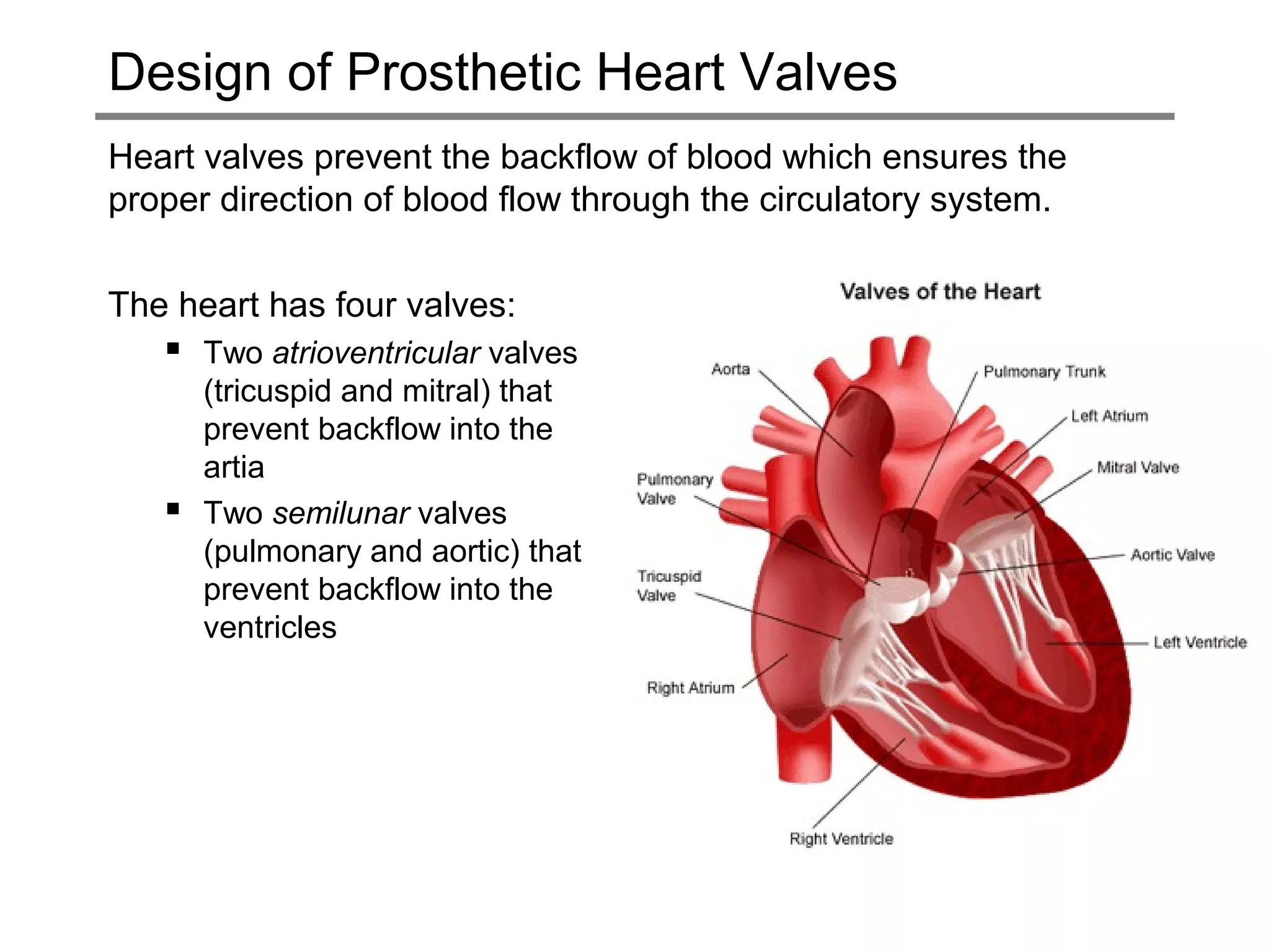

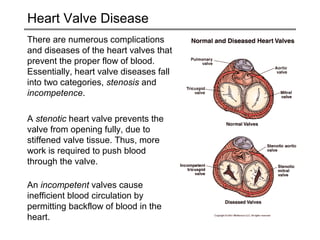

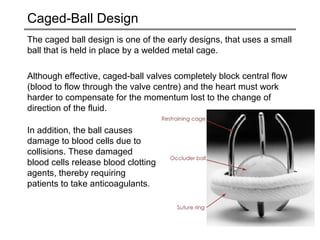

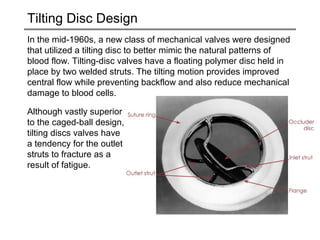

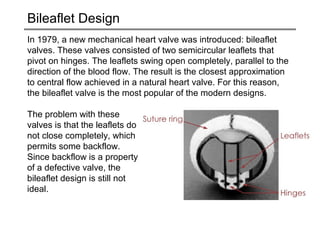

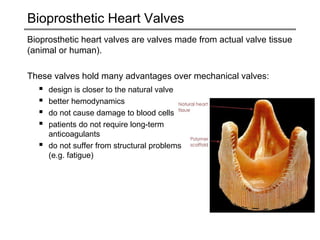

This document discusses the design and evolution of prosthetic heart valves. It describes the two main types as mechanical and bioprosthetic valves. Mechanical valves have improved over time from early ball valve designs to modern bileaflet valves, but still require patients to take blood thinners. Bioprosthetic valves use animal or human tissue and have advantages like similar design to natural valves and not requiring blood thinners, but are susceptible to calcification over 10-15 years. The document outlines the anatomy and diseases of natural heart valves to provide context on why prosthetic valves are needed.