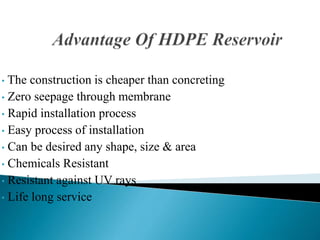

Geo membranes are flexible synthetic sheets used for covering earth, with HDPE being the most popular type due to its flexibility, UV resistance, and cost-effectiveness. HDPE is made from petroleum, known for its strength and is commonly recycled, with applications in water reservoirs and various containers. The installation process is efficient, resistant to chemicals and UV rays, and provides a long-lasting solution for water preservation, making it a viable option for managing water scarcity.