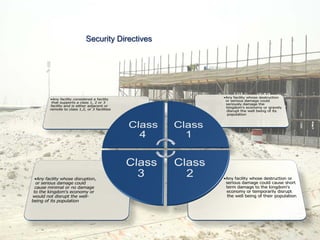

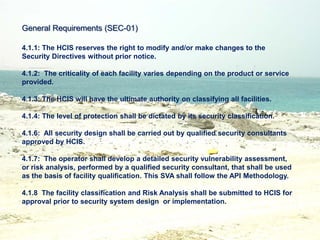

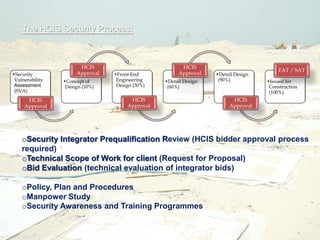

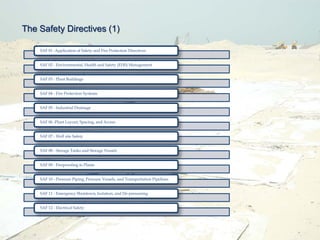

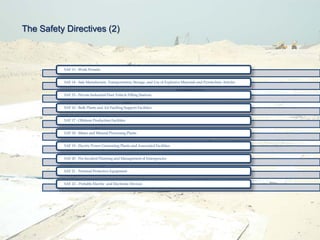

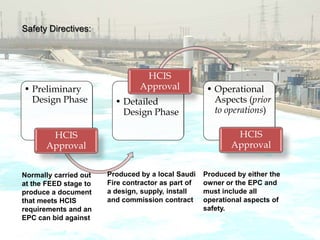

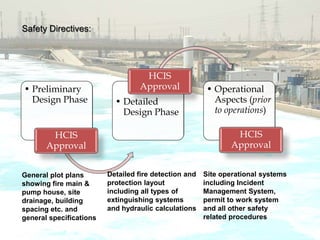

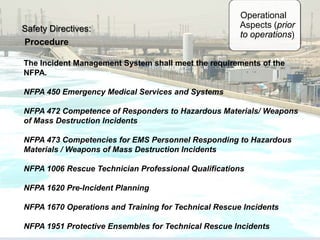

The document discusses new security and safety directives issued by the High Commission for Industrial Security (HCIS) in Saudi Arabia that must be applied to all new and existing industrial projects and facilities. It outlines the HCIS approval process for security and safety designs and systems. This involves conducting a security vulnerability assessment, developing preliminary and detailed designs, and obtaining HCIS approval at various stages. It also discusses general requirements and specific directives for security measures, fire protection systems, and developing an incident management system to ensure safety. Non-compliance with the new standards may result in serious consequences for plant owners.