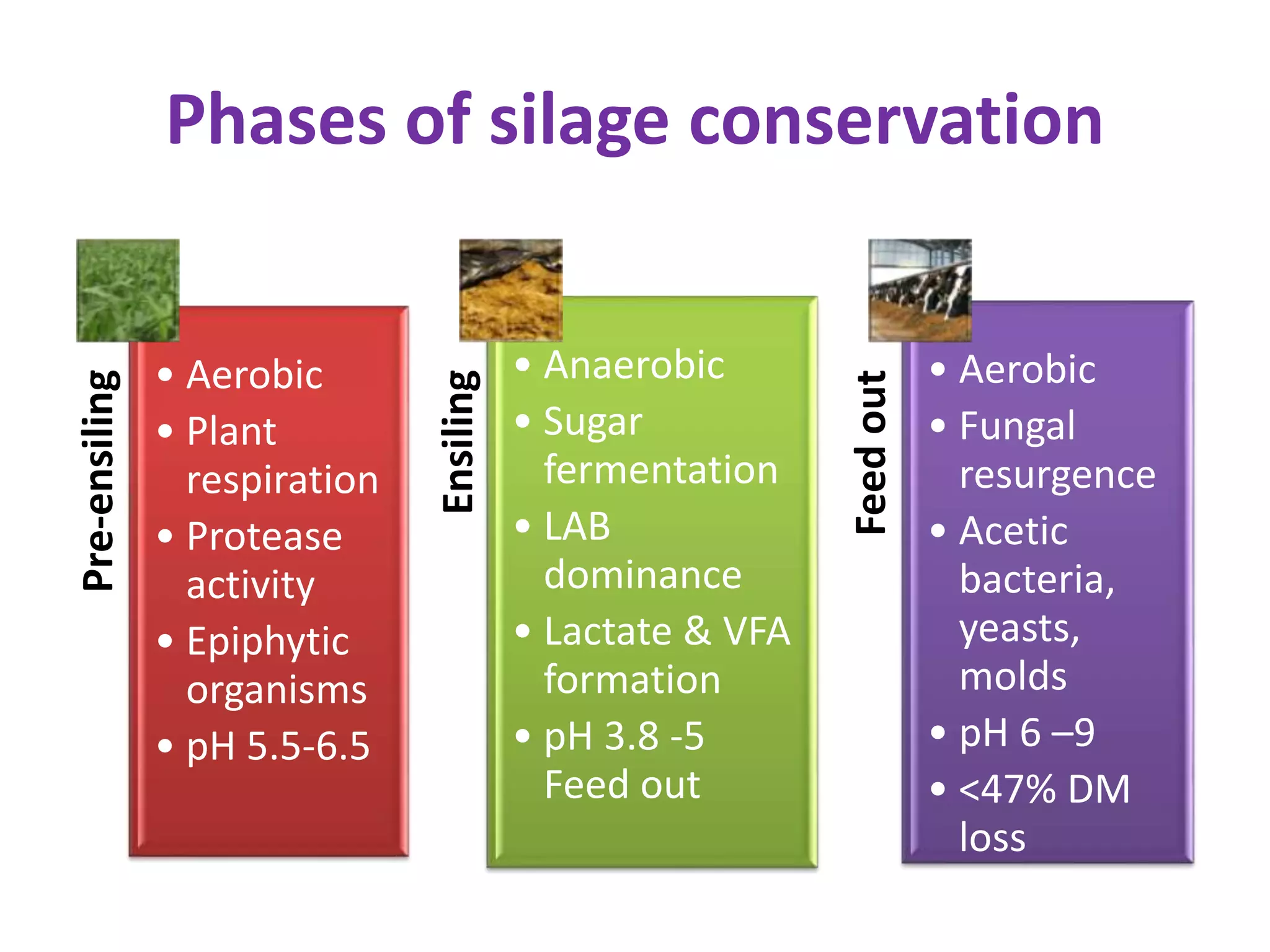

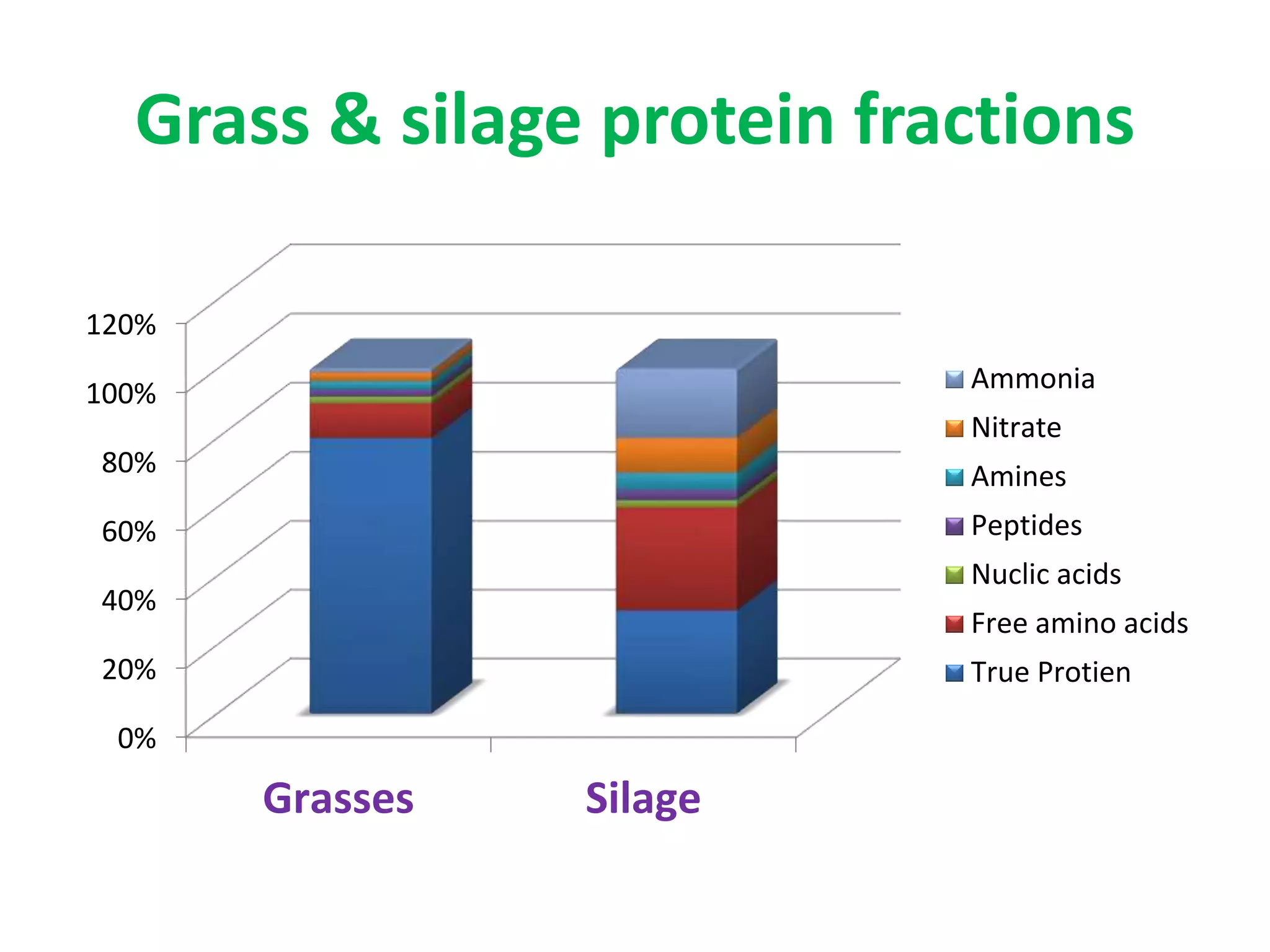

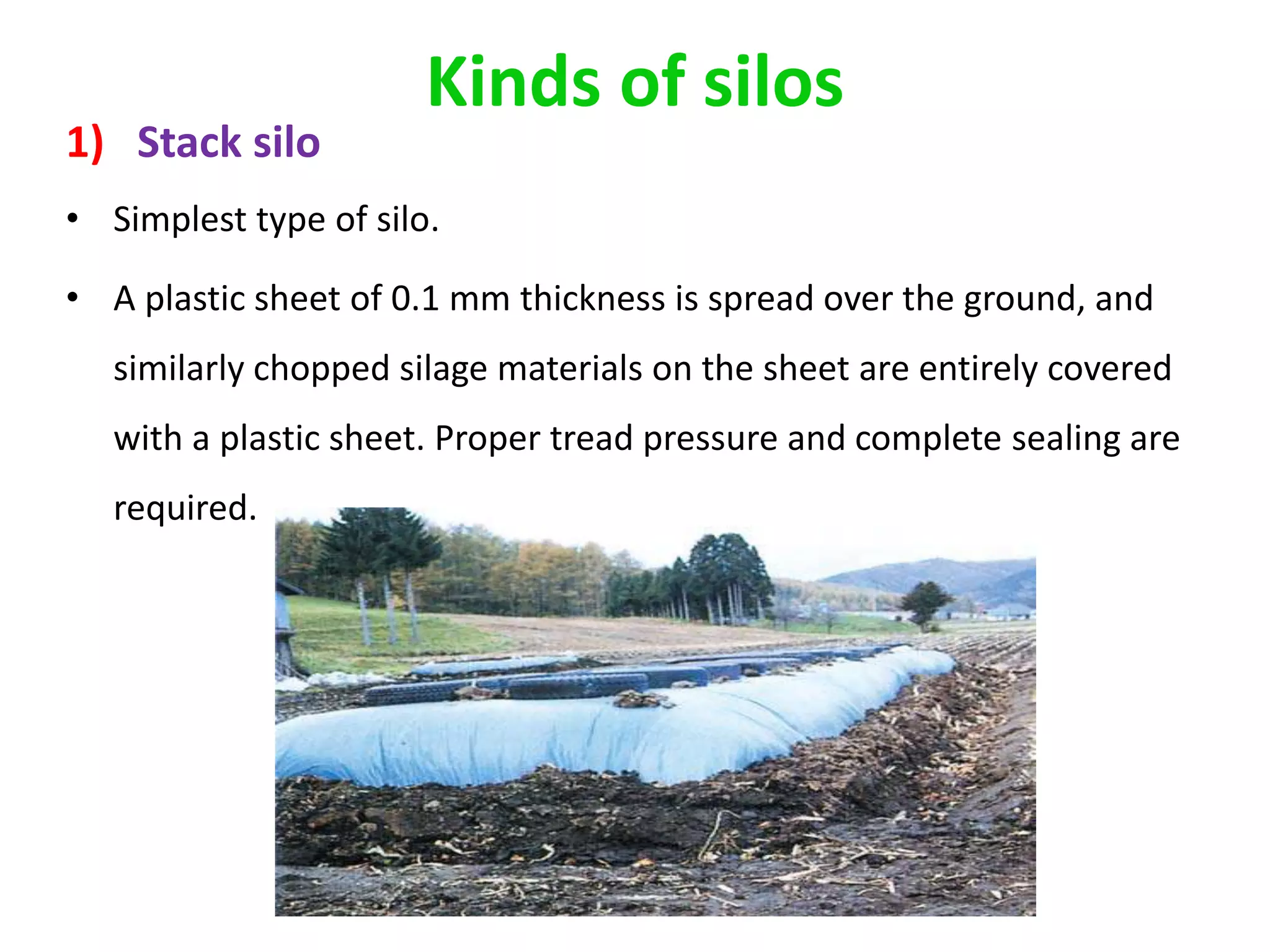

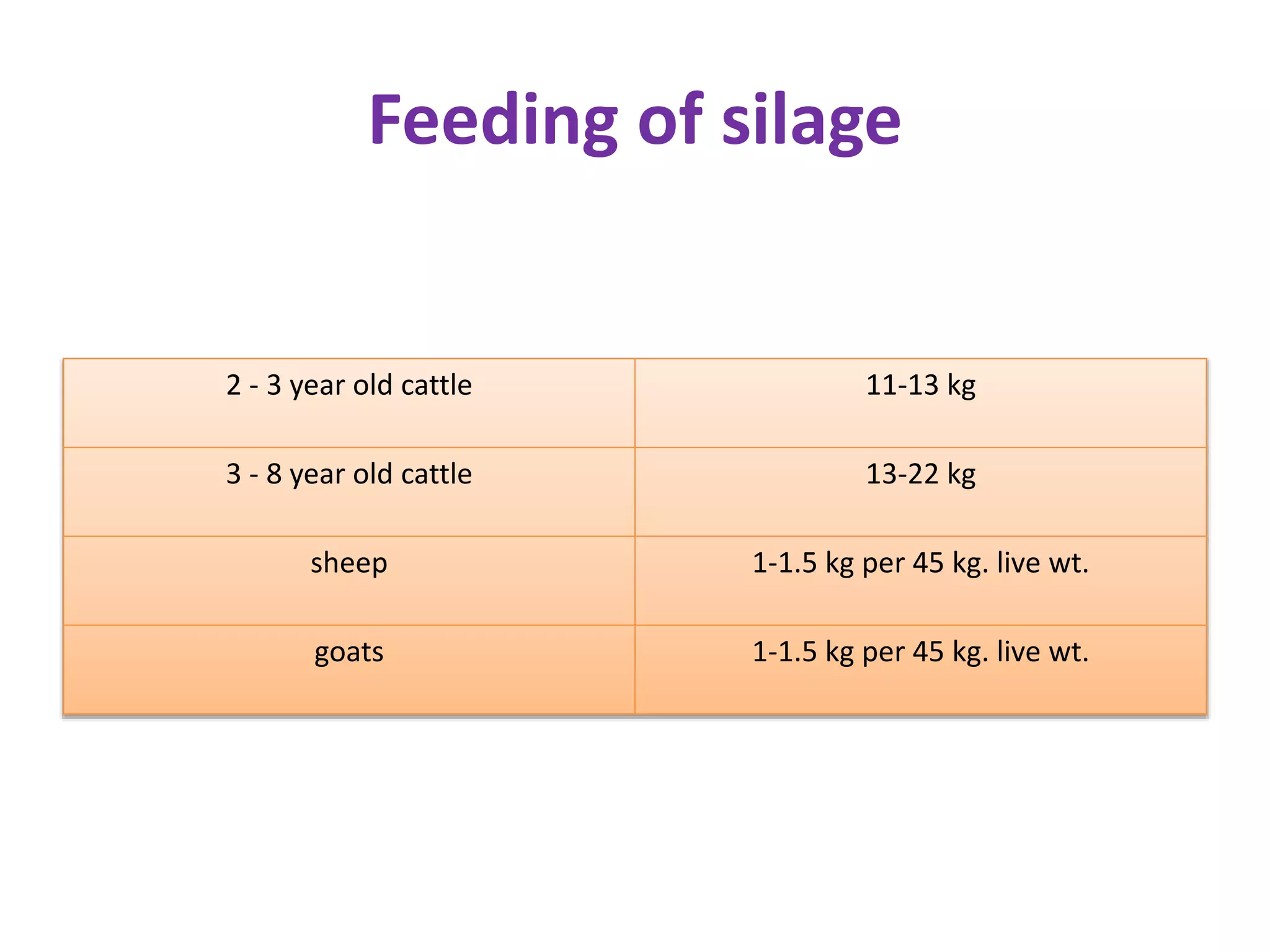

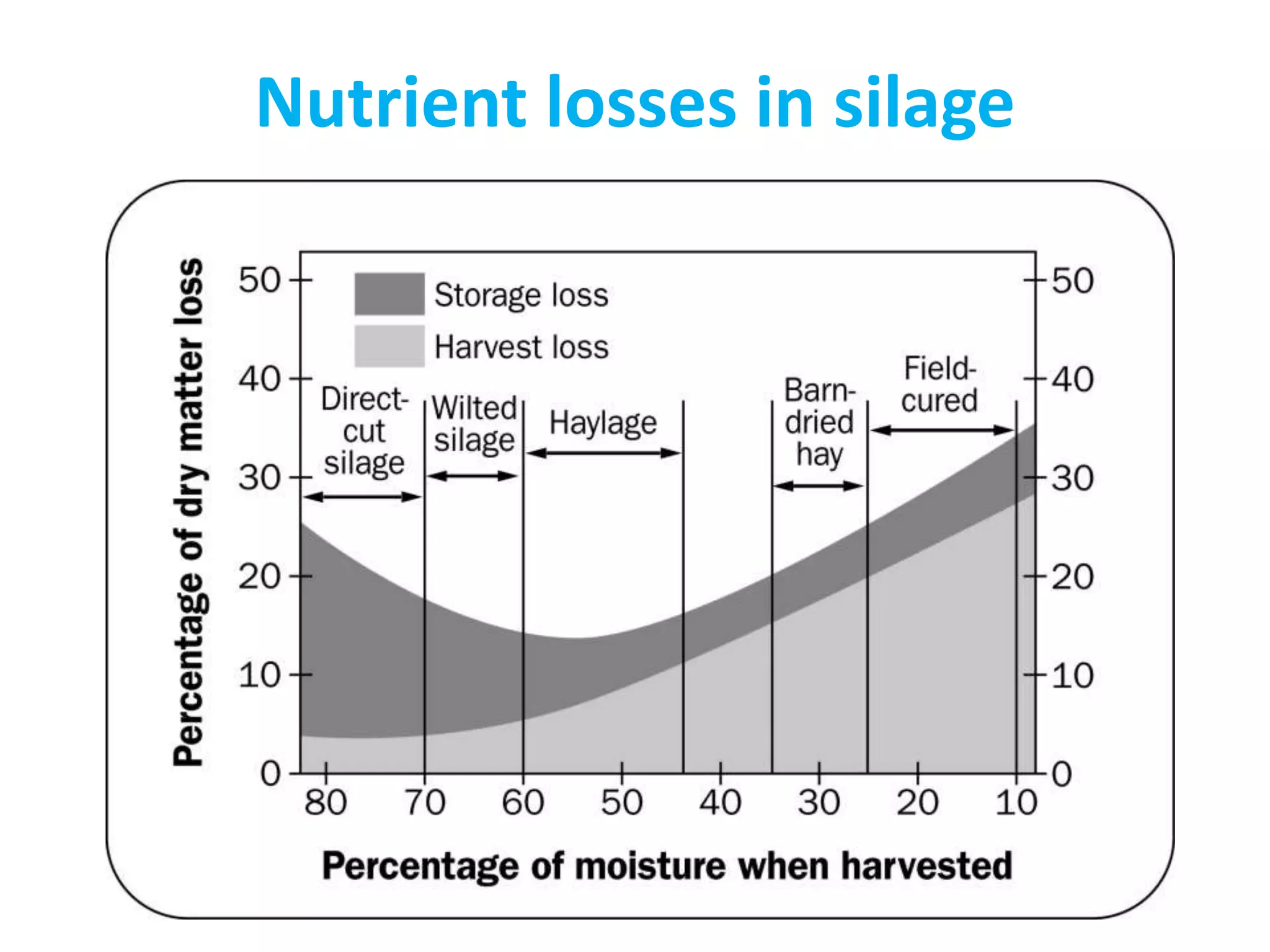

The document provides a comprehensive overview of fodder conservation through silage making, detailing its purpose, methods, advantages, and the principles involved in the fermentation process. It covers the selection of crops, construction of silos, methods for making silage, and the use of additives to enhance quality and nutrient recovery. Additionally, it discusses the fermentation stages and criteria for judging silage quality, including feeding recommendations and nutrient loss factors.