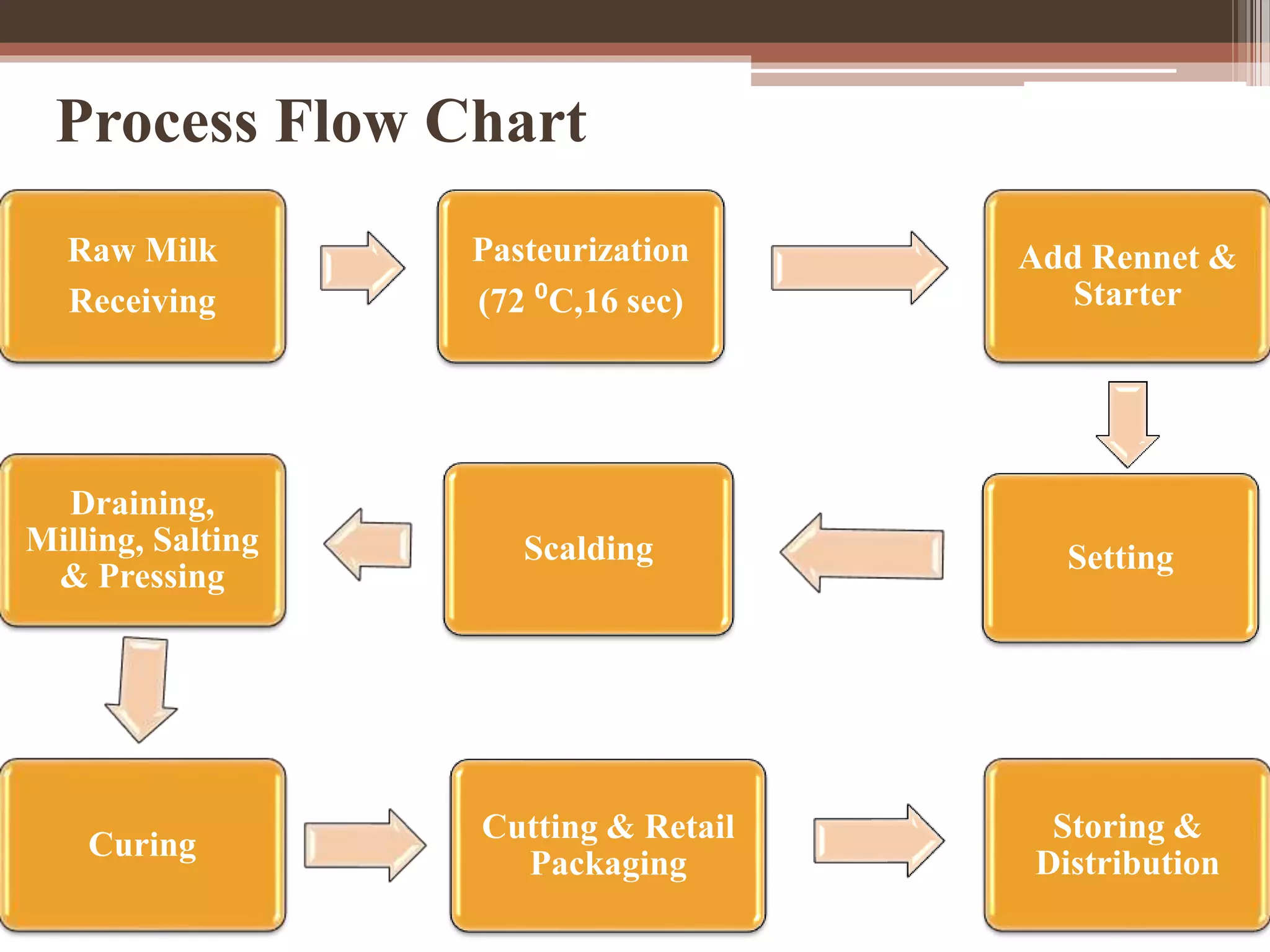

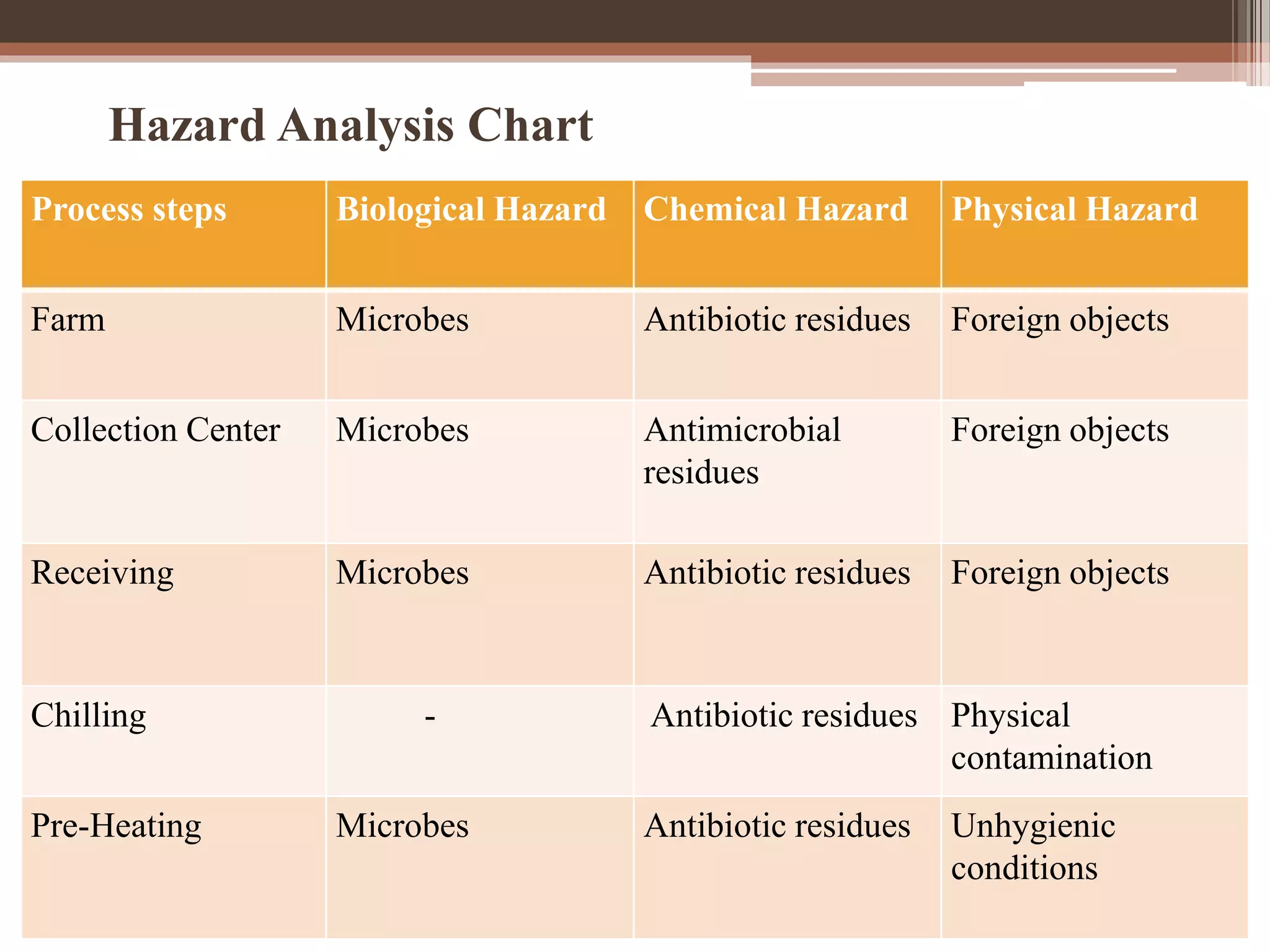

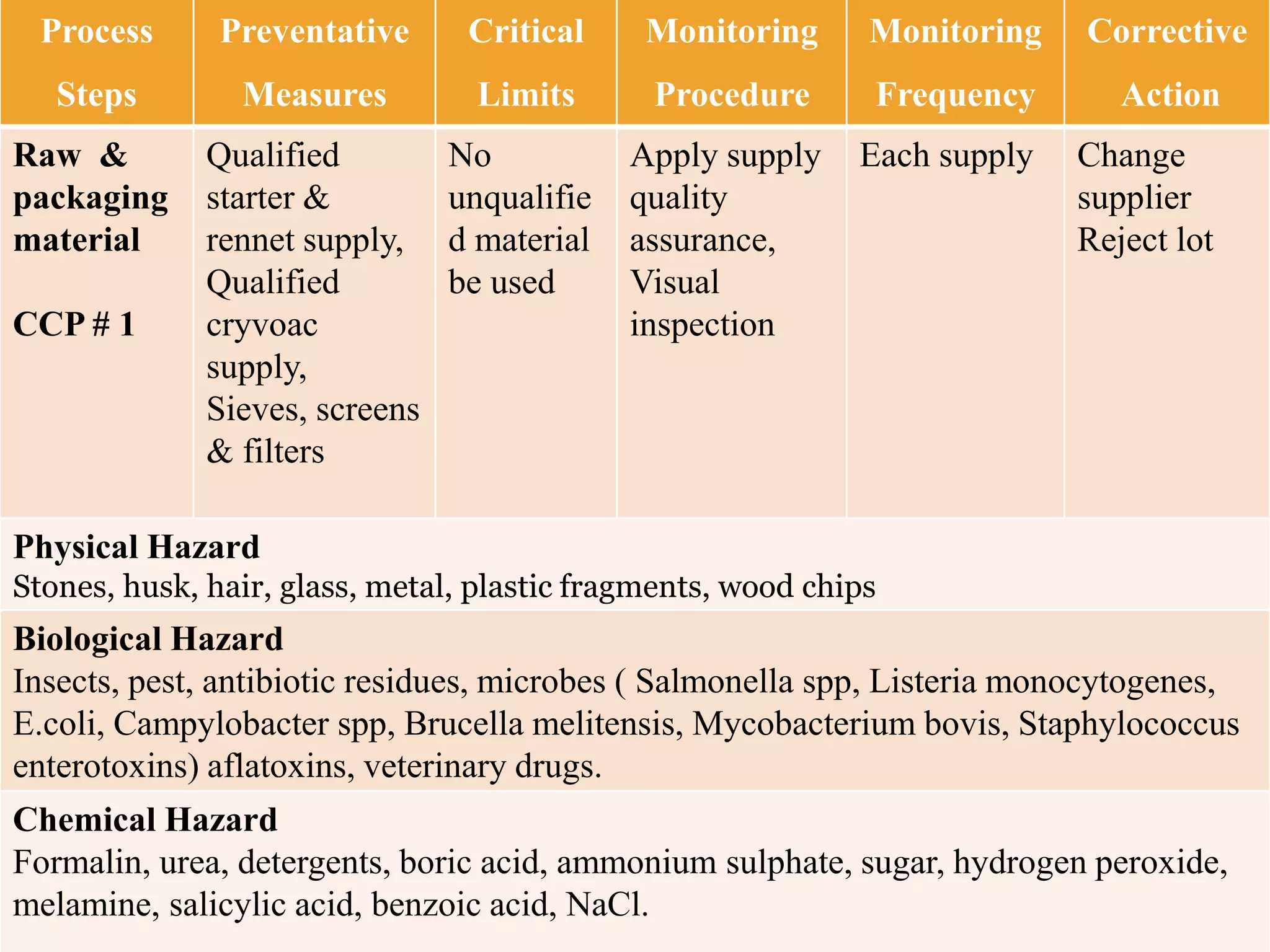

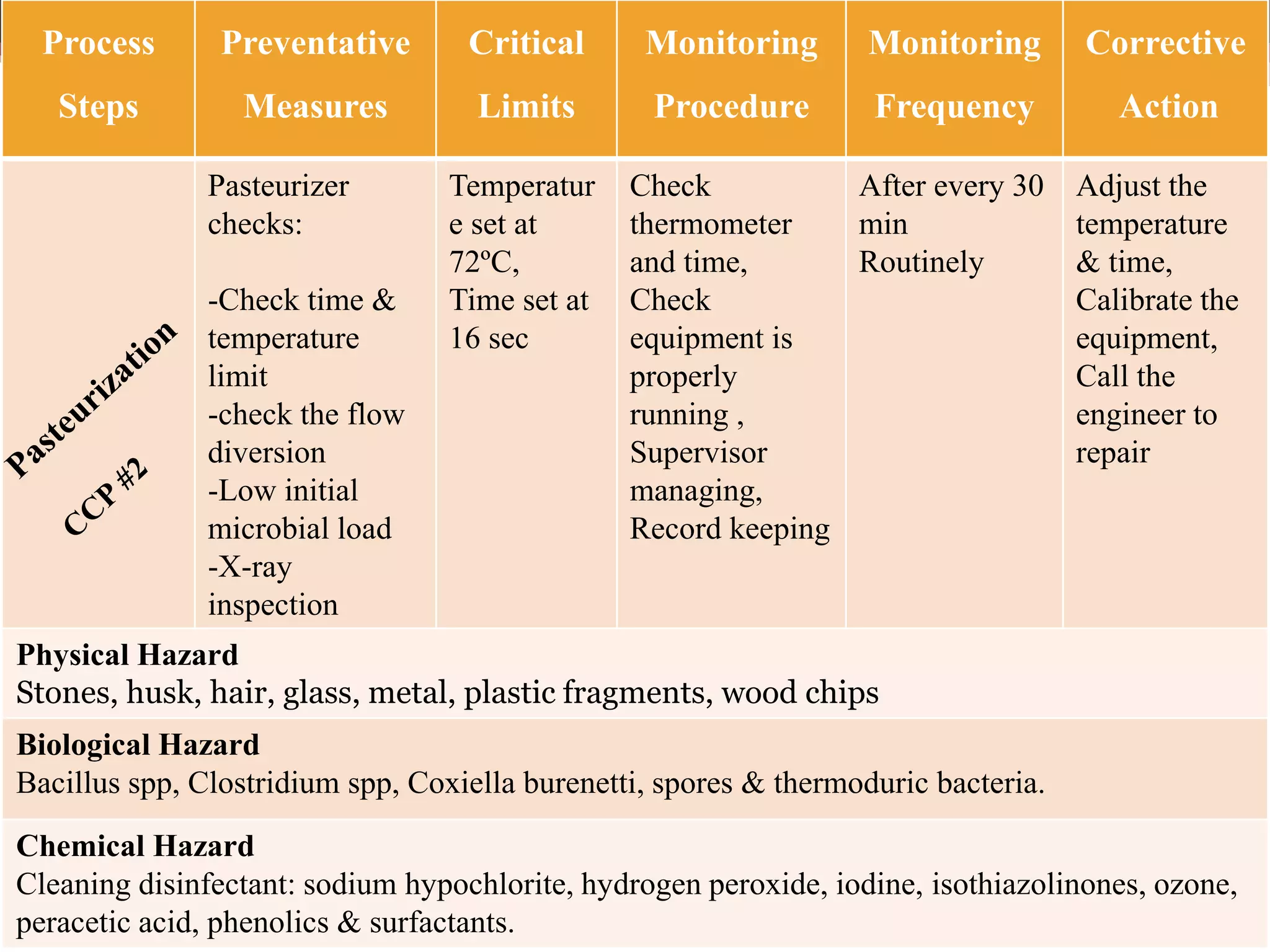

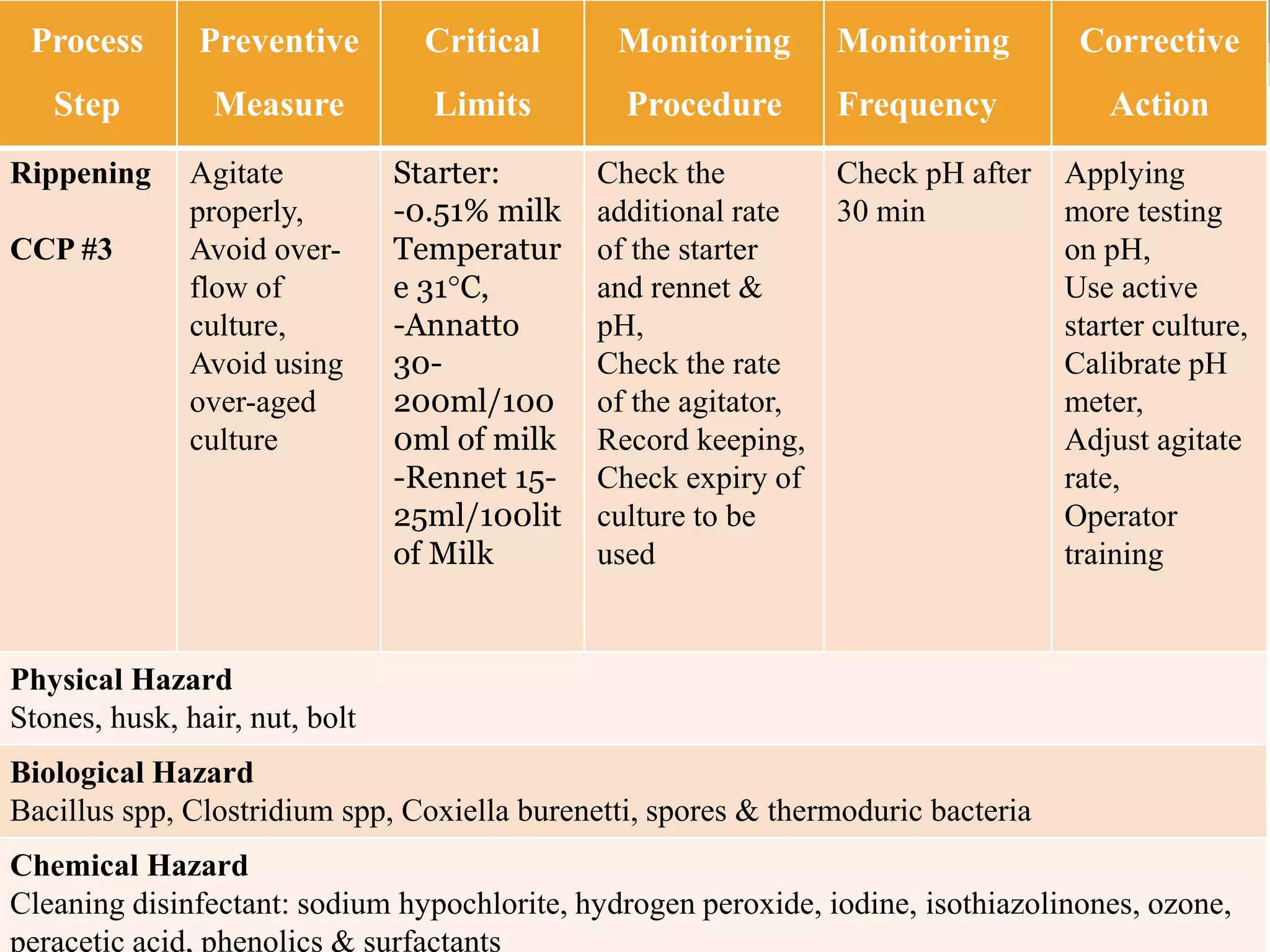

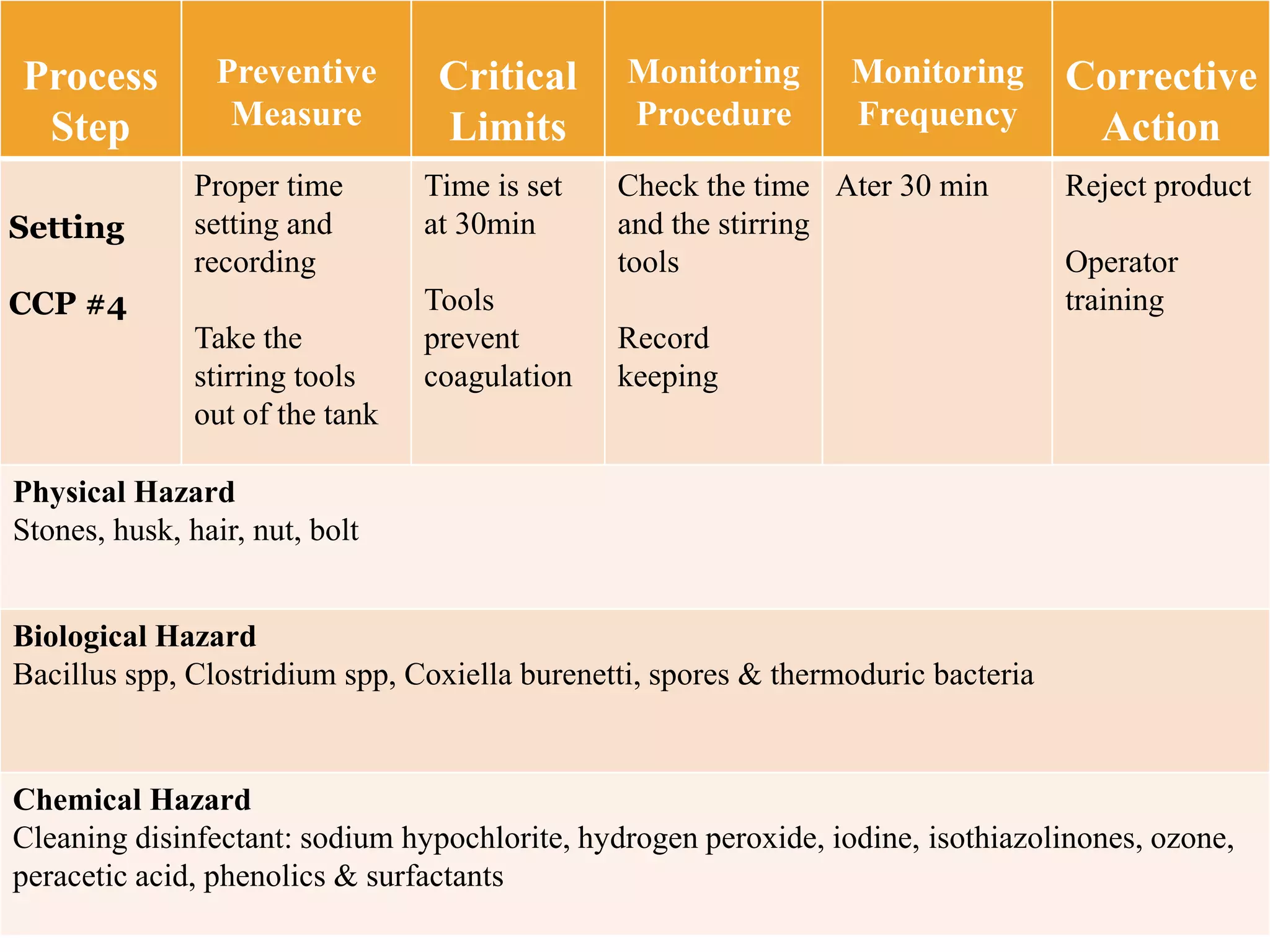

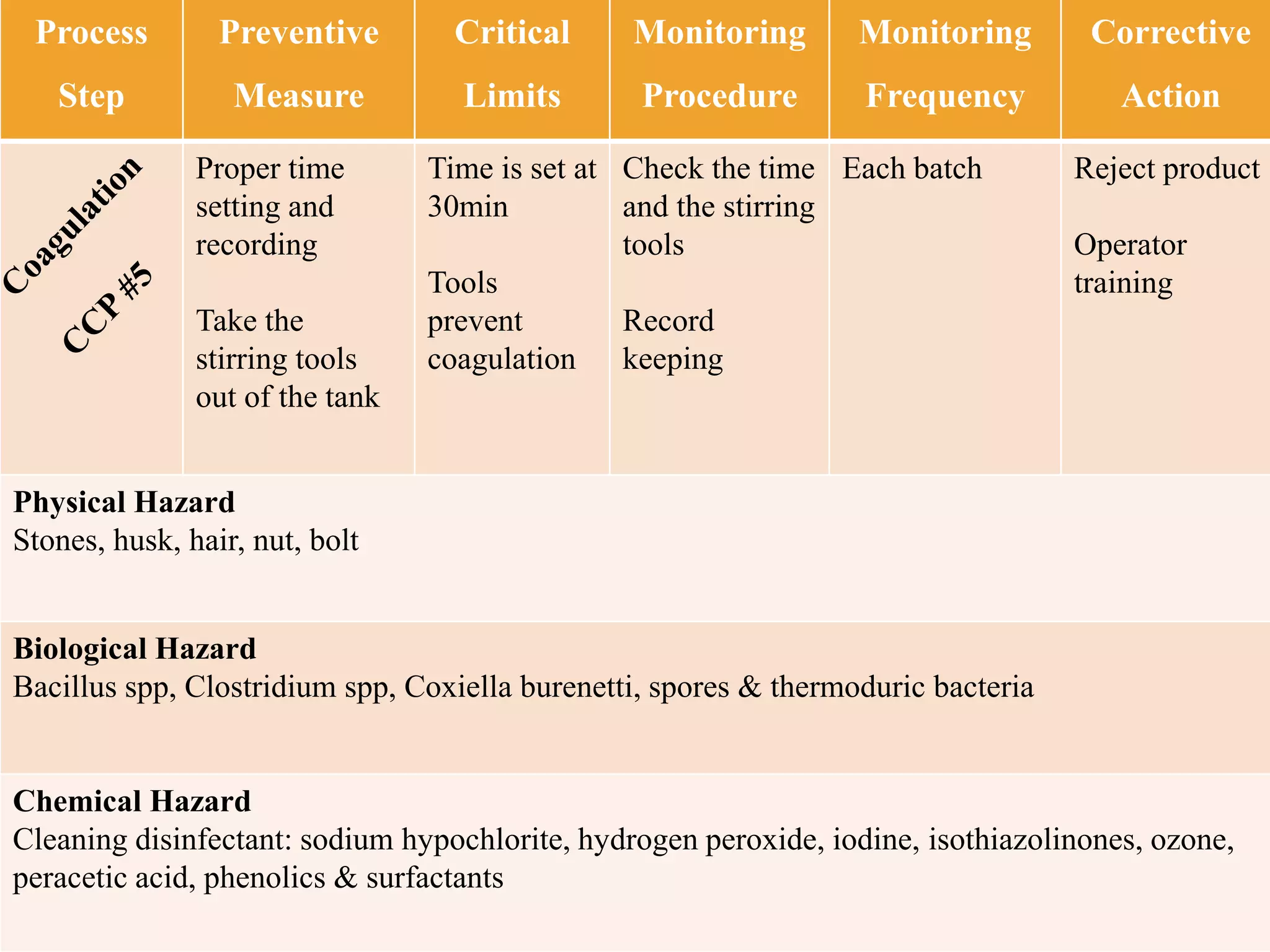

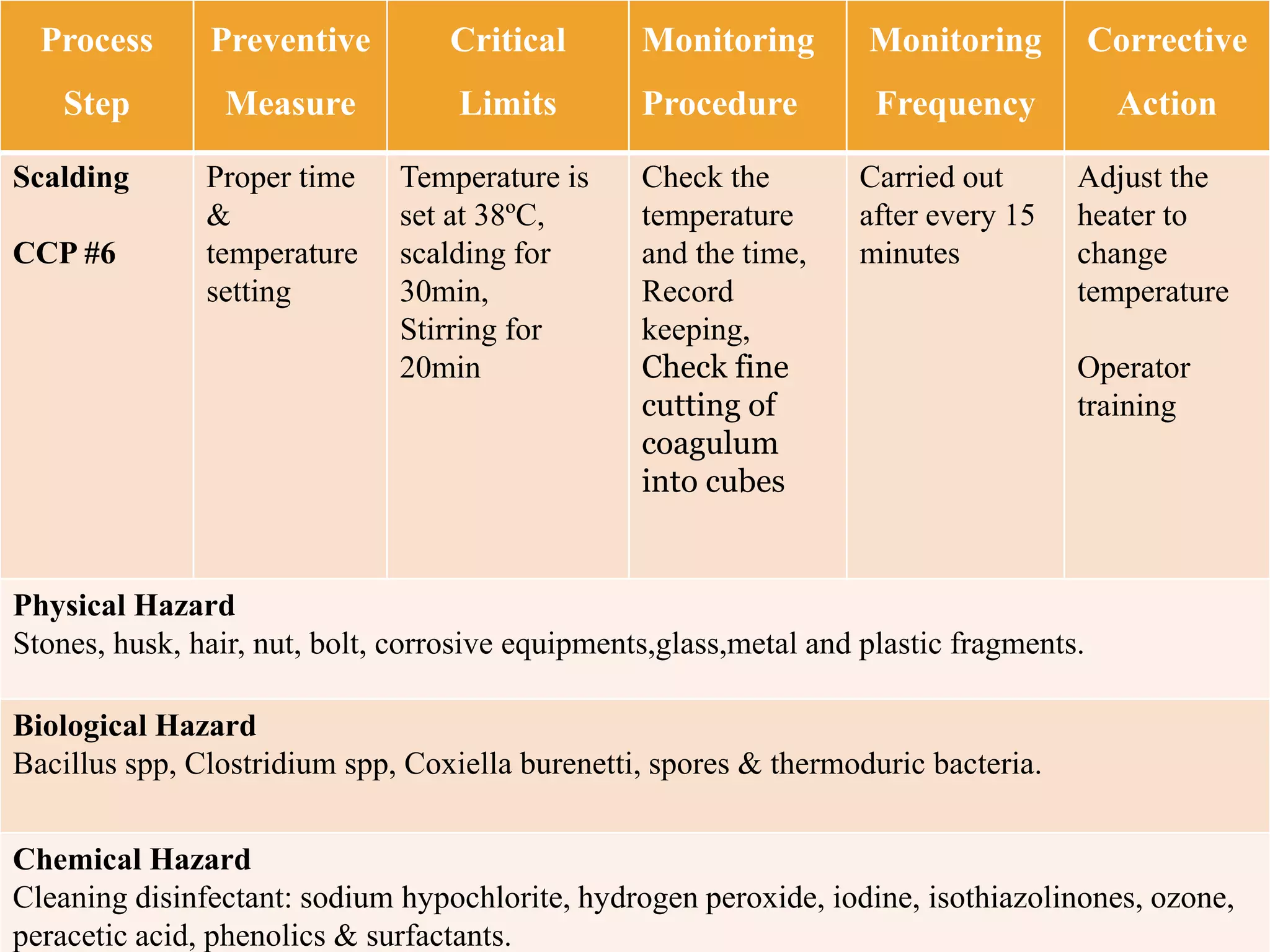

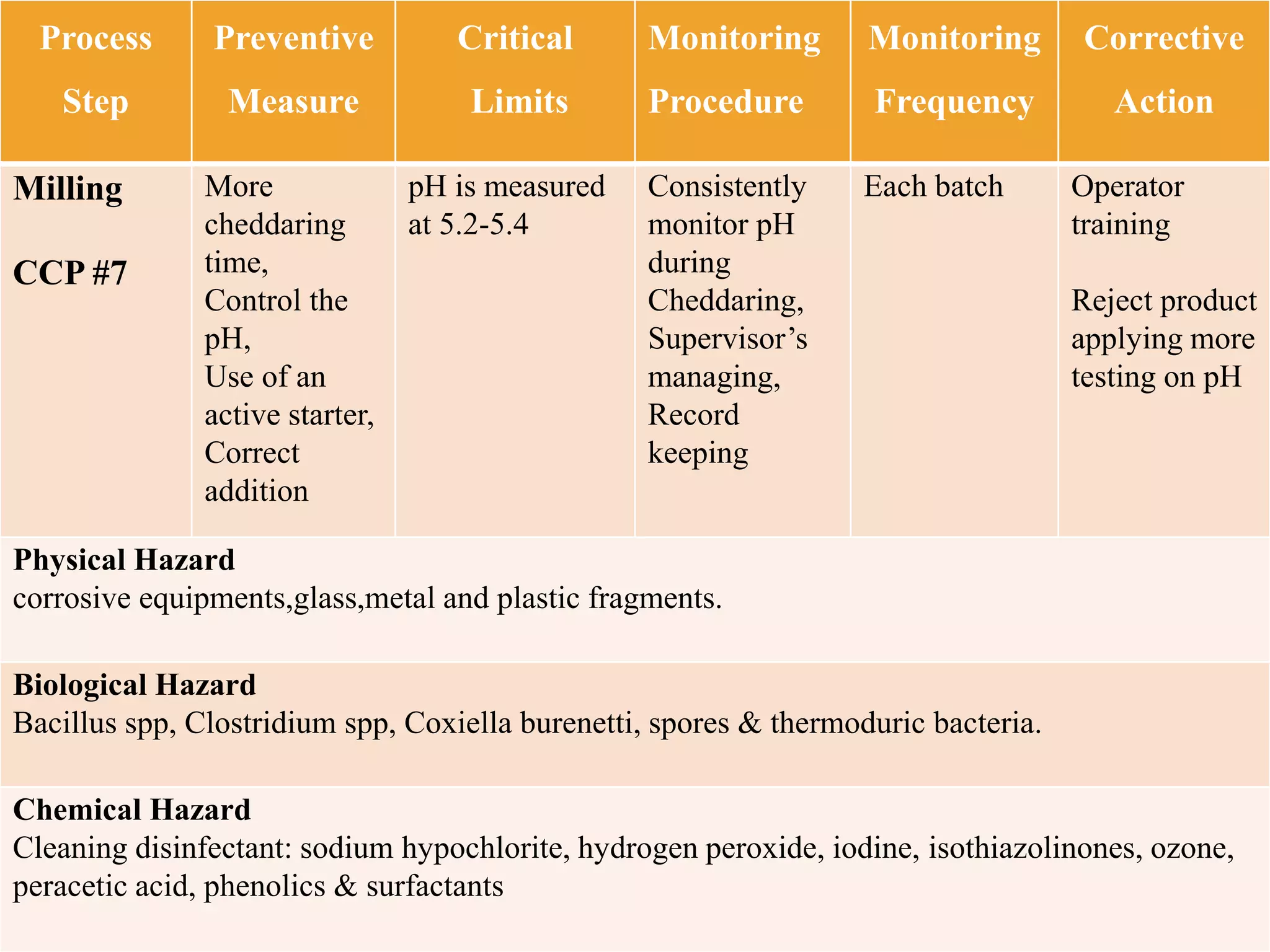

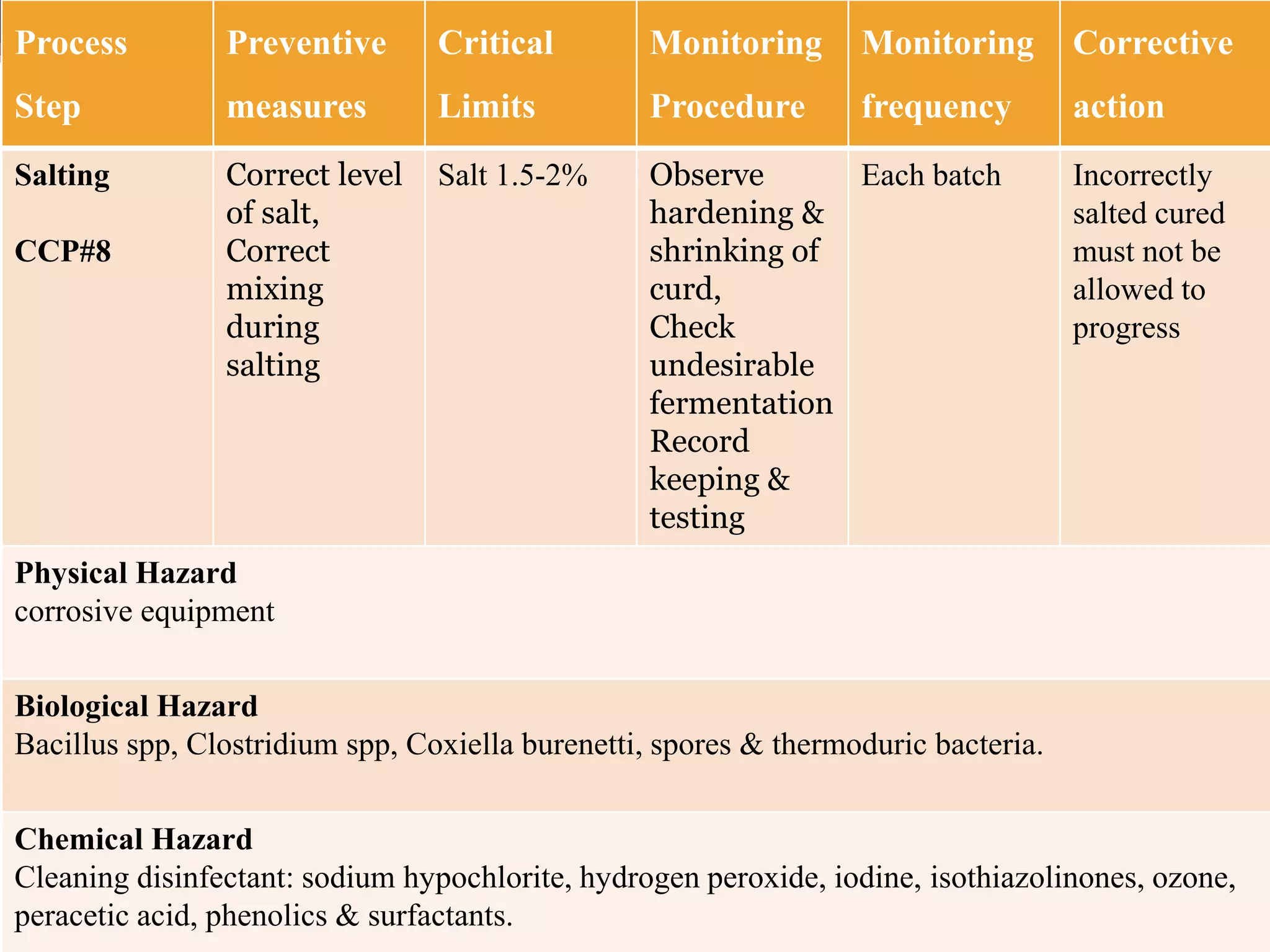

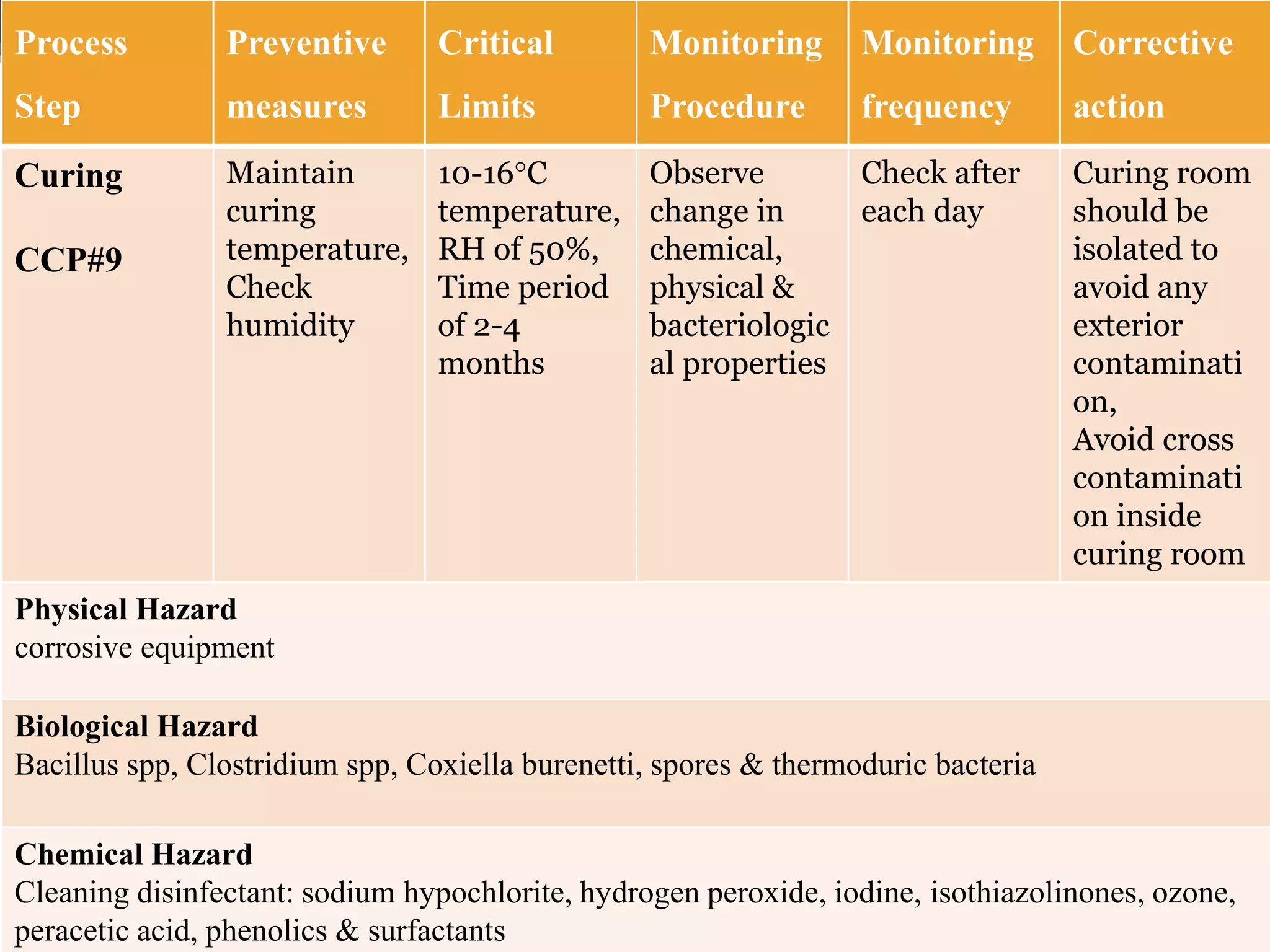

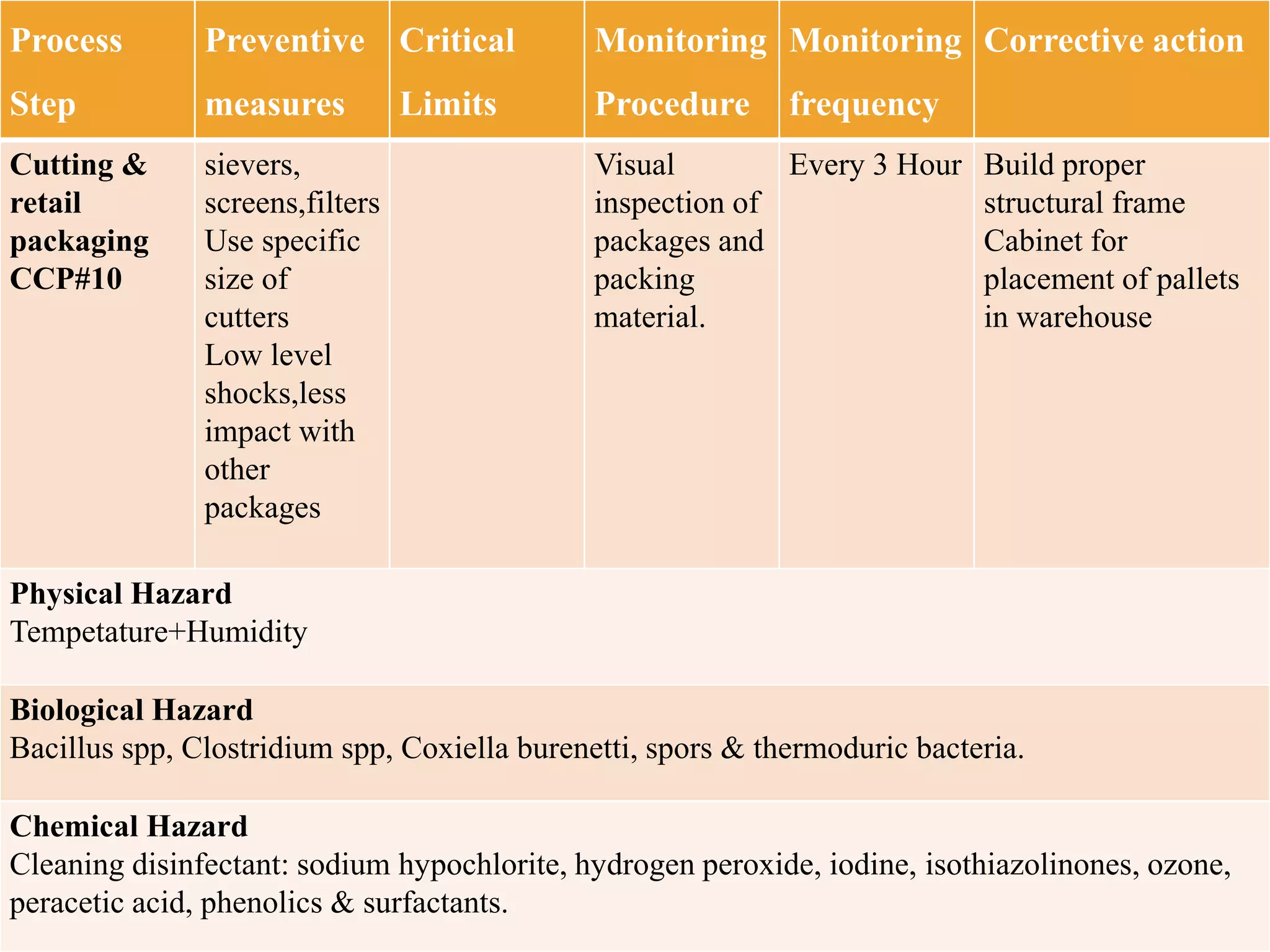

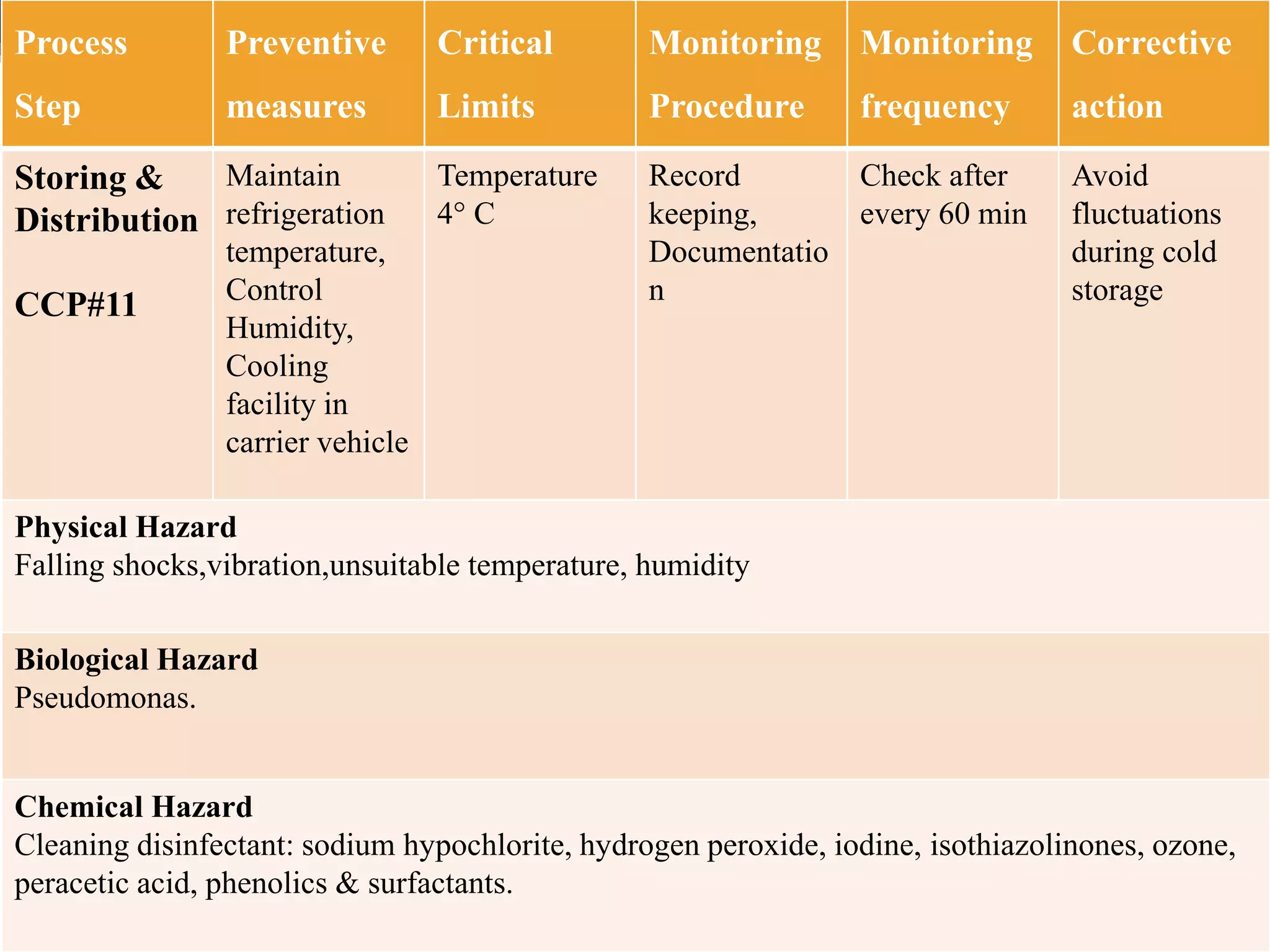

This document outlines the HACCP implementation plan for a cheddar cheese production process. It begins with an overview of cheddar cheese and describes the process flow chart. It then identifies potential biological, chemical and physical hazards at each process step. For key steps identified as critical control points, it lists preventative measures, critical limits, monitoring procedures, frequency and corrective actions. The 11 process steps covered are raw milk receiving, pasteurization, ripening, setting, scalding, milling, salting, curing, cutting, packaging and storage/distribution. References are provided to support the HACCP analysis.