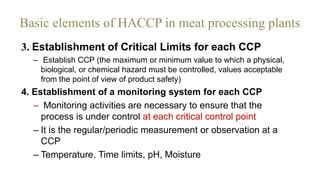

The document outlines meat hygiene practices essential for ensuring the safety and suitability of meat during processing, including cleaning, sanitation, and hazard control. It emphasizes the importance of good hygienic practices and the Hazard Analysis Critical Control Point (HACCP) system in preventing contamination and maintaining meat quality. Key principles discussed include microbial contamination prevention, minimizing microbial growth, and implementing suitable heat treatment and packaging.