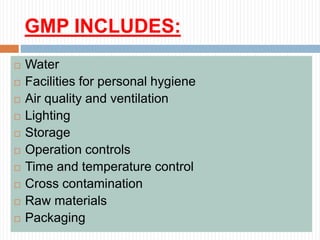

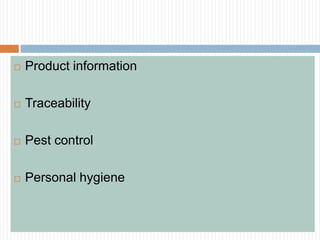

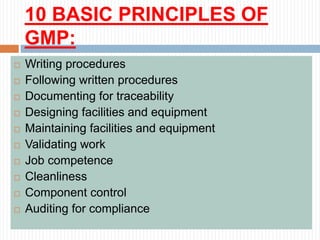

The document provides an overview of Good Manufacturing Practices (GMP). It discusses that GMPs are procedures and universal steps that provide basic environmental conditions and management systems necessary for safe food production. It outlines 10 key areas of GMP including facilities, equipment, water supply, waste disposal, cleaning, and personnel practices. The document emphasizes that GMPs focus on preventative measures and each facility must implement supervision and monitoring systems to ensure food safety.