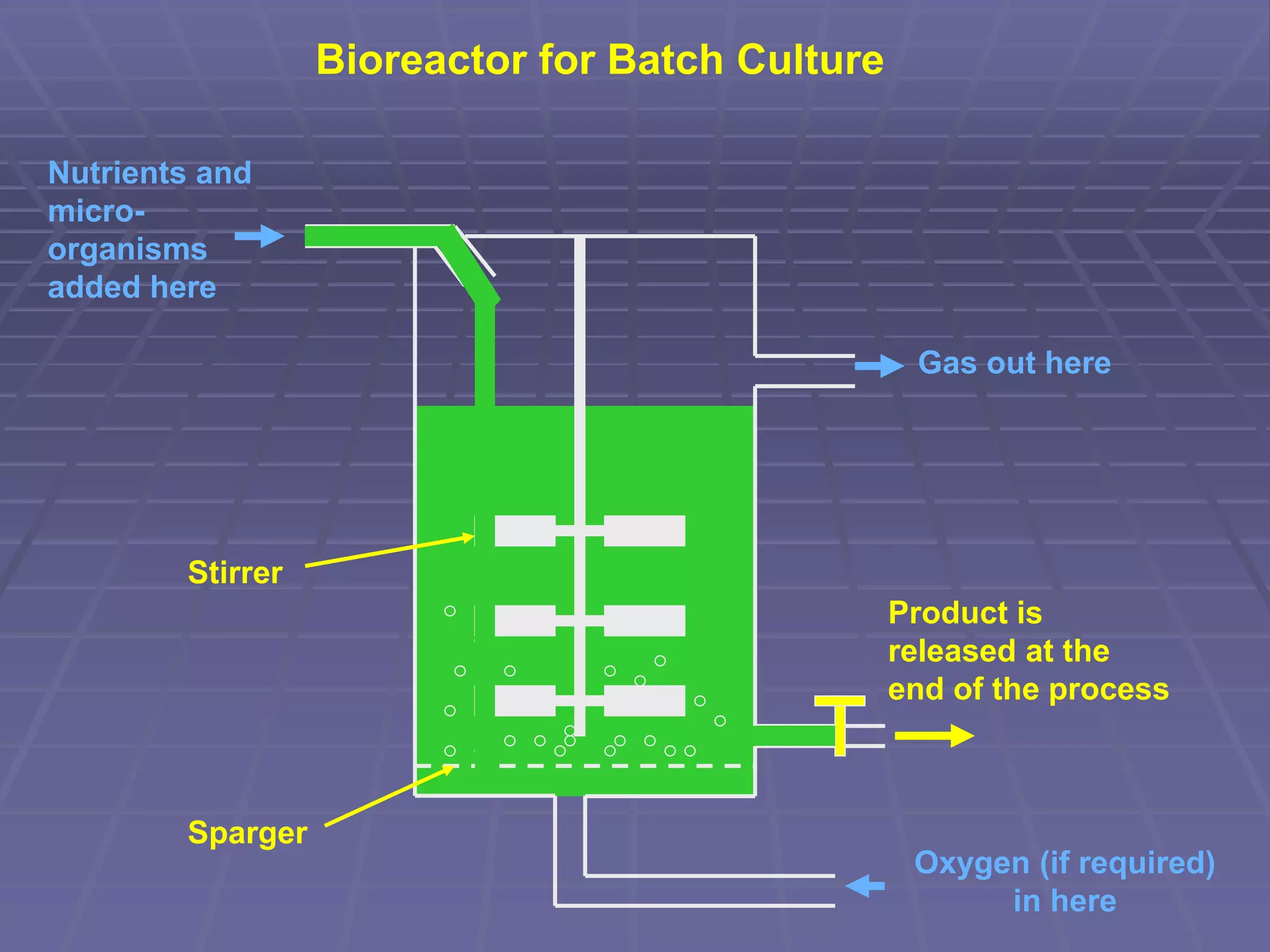

This document discusses the growth curves of microorganisms like bacteria and how their numbers are represented using a logarithmic scale. It then describes the four phases of bacterial growth - lag, log (exponential), stationary, and death phase. The log phase is when bacteria grow and divide most rapidly. The document also differentiates between batch and continuous culture methods for food processing using bioreactors, noting that continuous culture maintains bacteria in the log phase for ongoing production.

![Limitation of log or exponential phase

Exhaustion of nutrition

Accumulation of toxic metabolites end

products

Rise in cell density

Change in PH

[Log phase is the time when cells are most

active metabolically and is preferred for

industrial purpose]](https://image.slidesharecdn.com/growthcurves-170226153721/75/Growth-curves-8-2048.jpg)