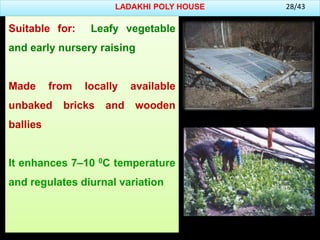

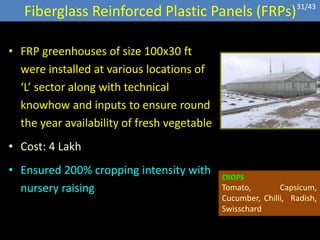

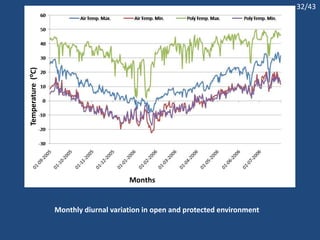

This document summarizes the benefits of greenhouse technology. Greenhouses create a controlled environment that protects crops from extreme temperatures, wind, pests and diseases. This allows for year-round cultivation and higher yields compared to outdoor growing. Common greenhouse structures discussed include even-span, quonset and lean-to designs. The document also discusses greenhouse cultivation in Ladakh, India, where greenhouses have led to increased food production and economic benefits for local farmers in that harsh climate.