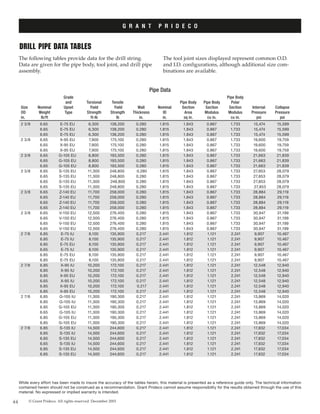

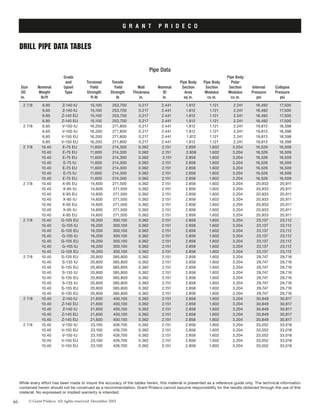

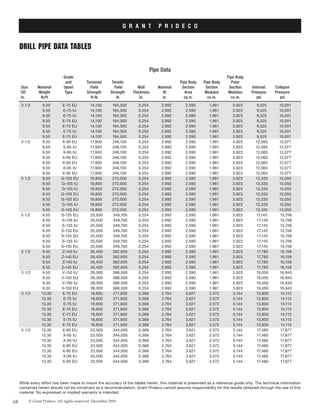

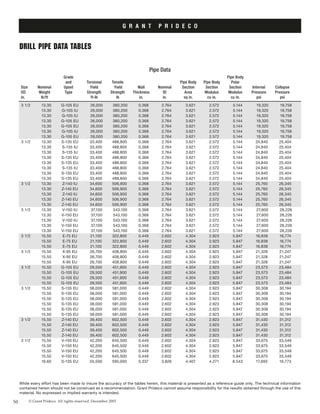

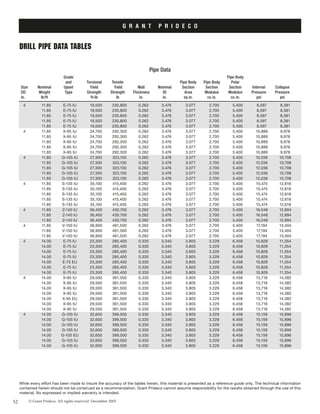

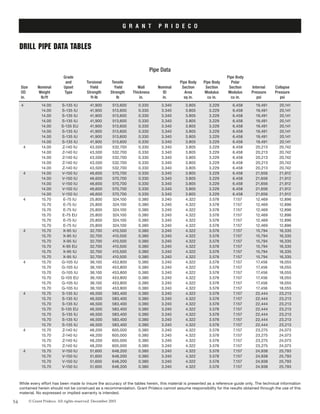

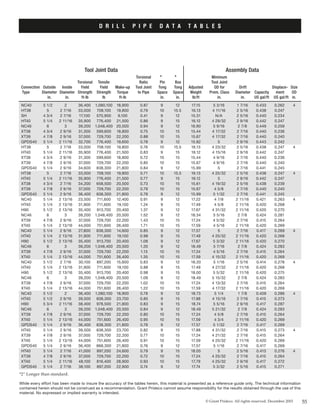

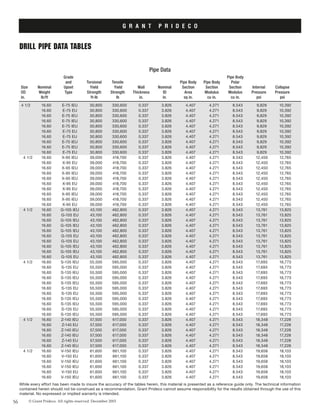

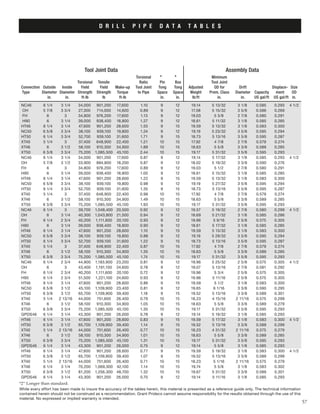

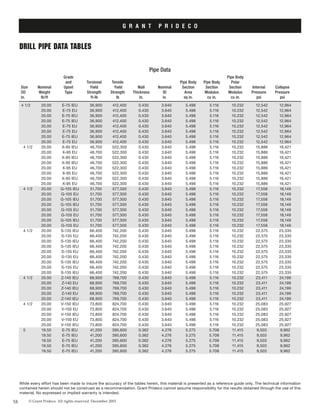

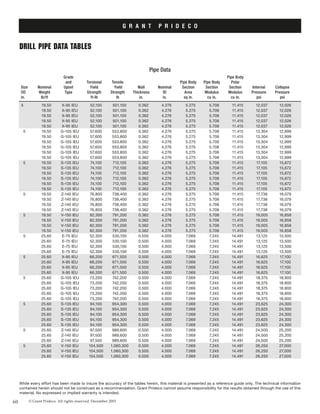

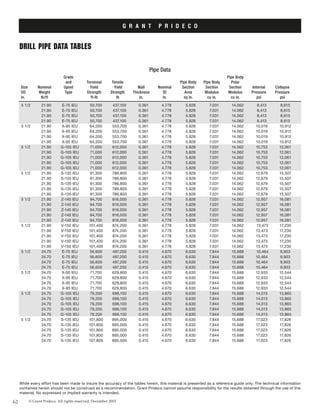

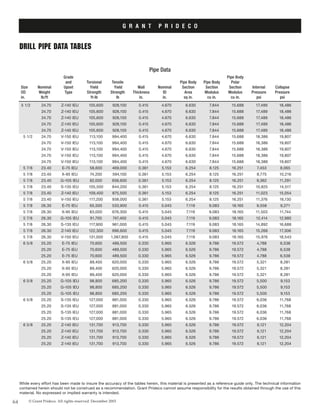

The document provides technical data and specifications for drill pipe assemblies, including dimensions, material properties, and performance metrics for the pipe body, tool joints, and complete drill pipe strings. Tables list measurements and ratings for different pipe sizes, materials, and configurations. The document aims to support reference and selection of drill pipe options but notes that accuracy cannot be guaranteed and no warranties are made regarding results from using the data.