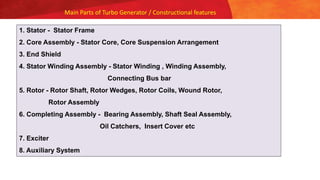

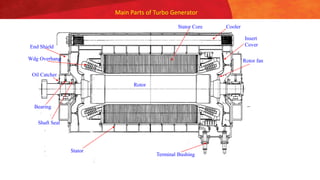

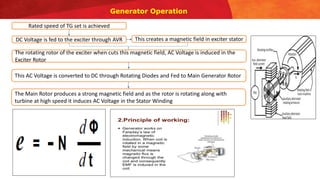

This document provides an overview of a knowledge sharing program on generator basics, excitation, protection systems, and overhauling and maintenance. The program is presented by a team of subject matter experts and is mentored by Nimai Mahapatra. The program covers topics such as generator working principles, classification, construction, excitation systems, protection systems, and overhauling testing. It also includes sections on generator basics and design aspects, synchronization, and operation.