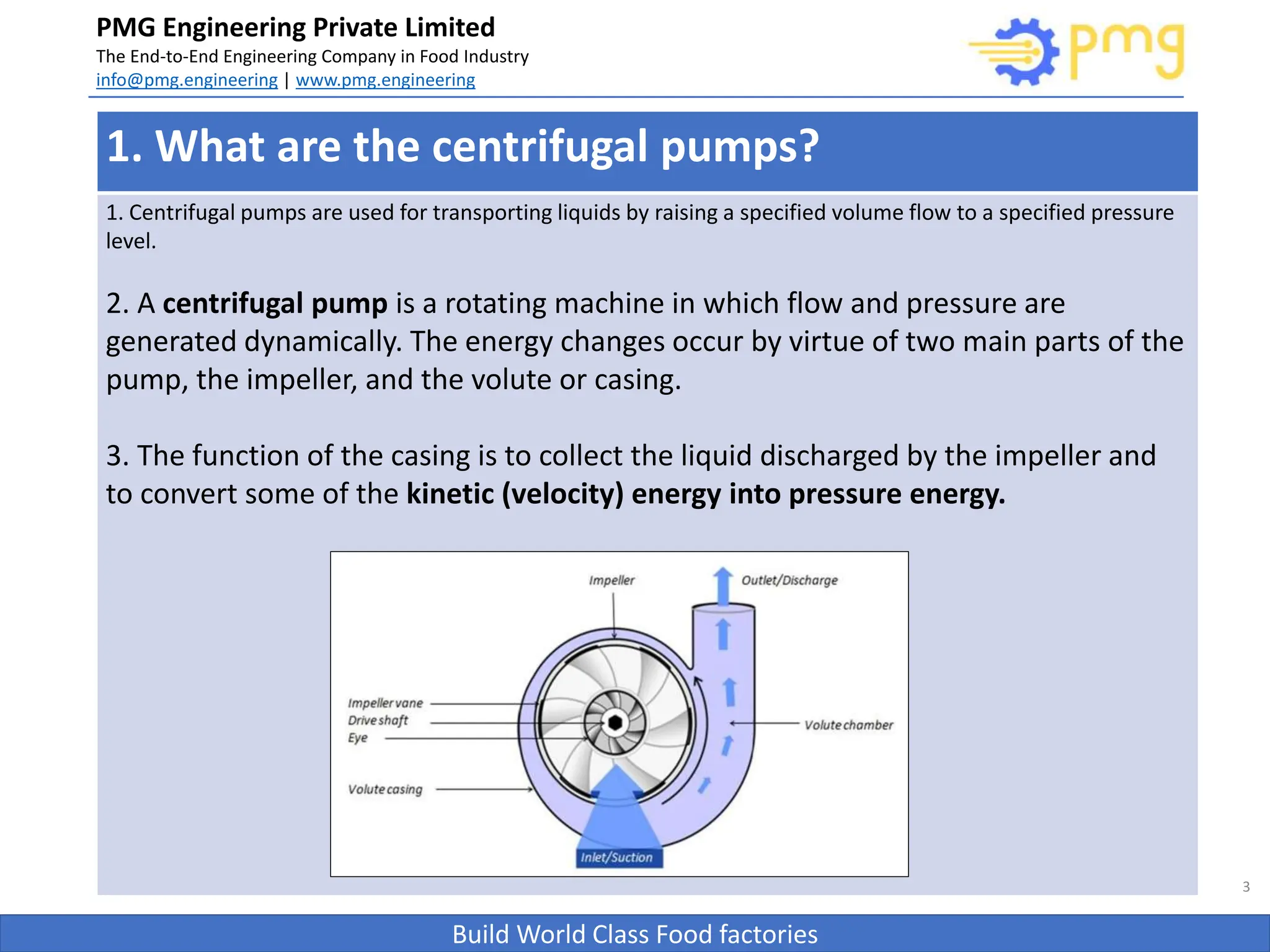

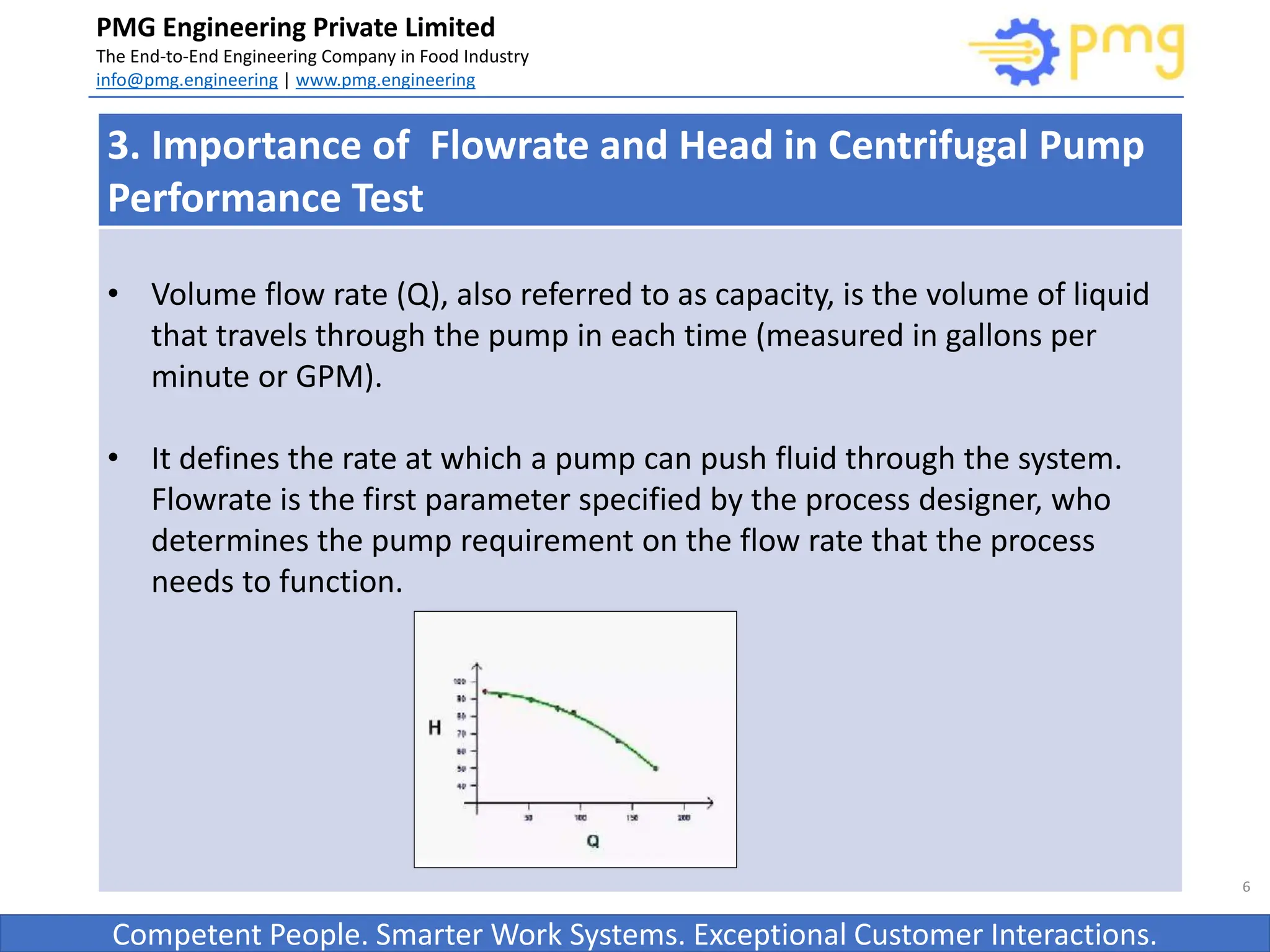

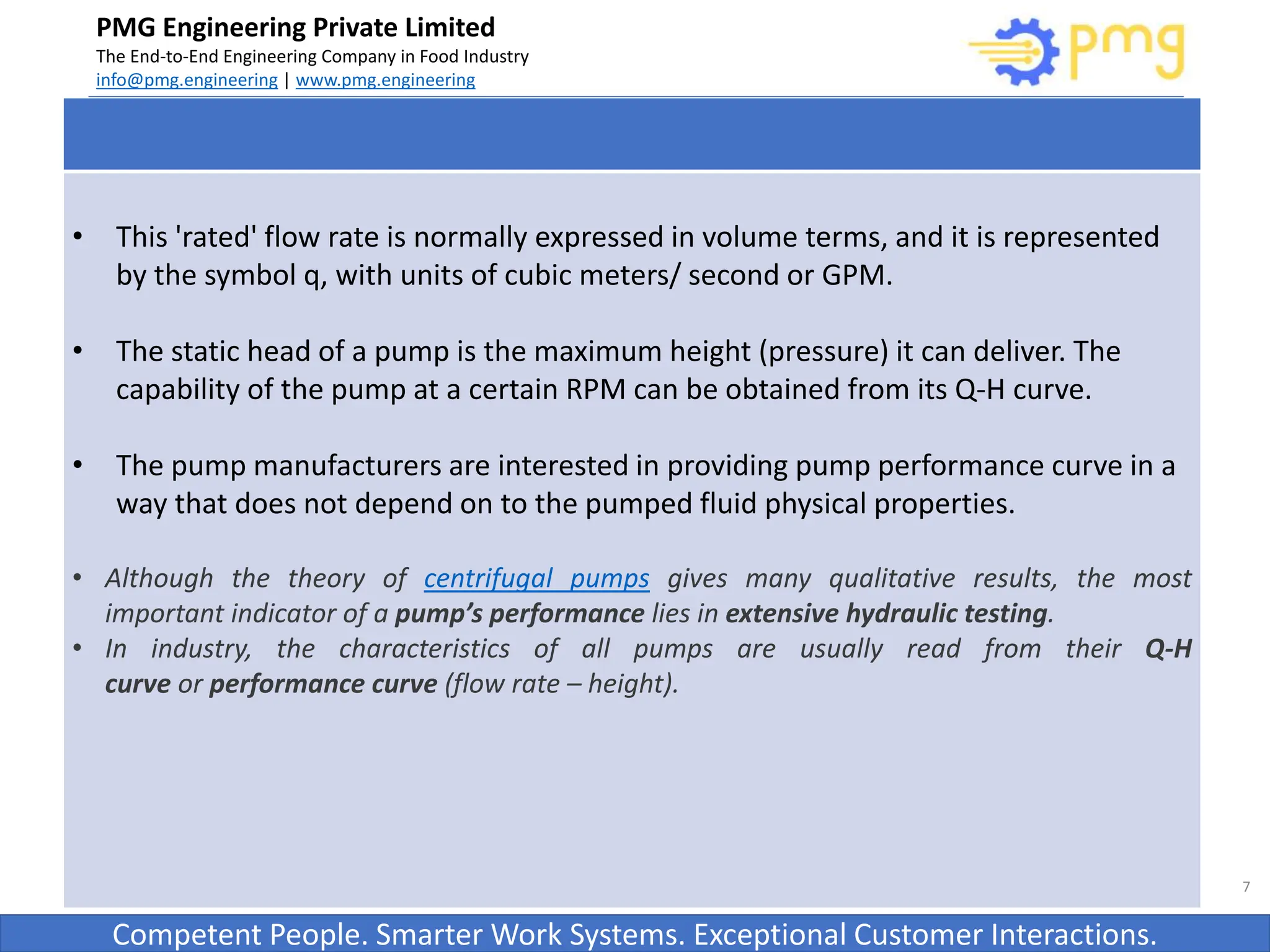

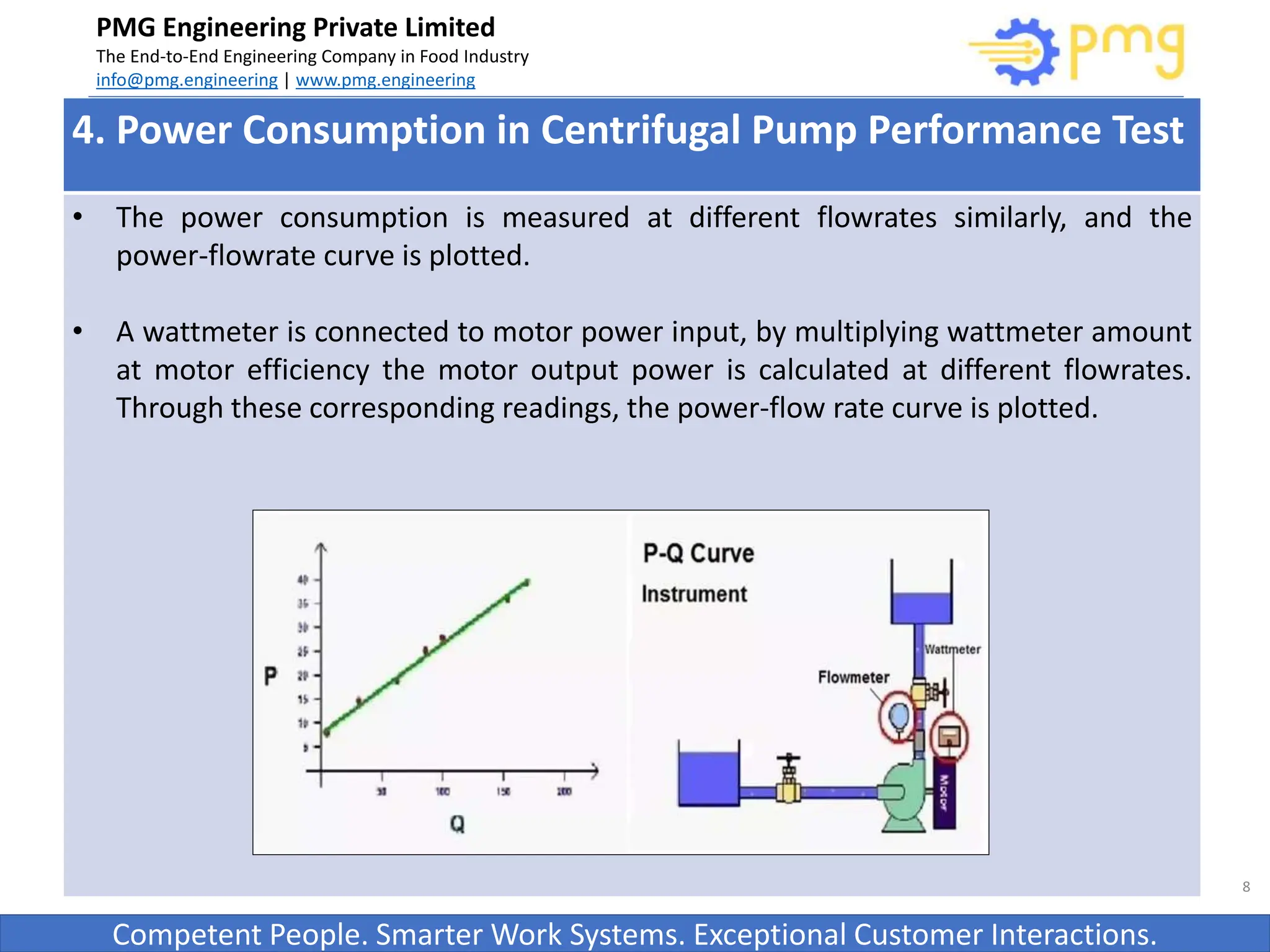

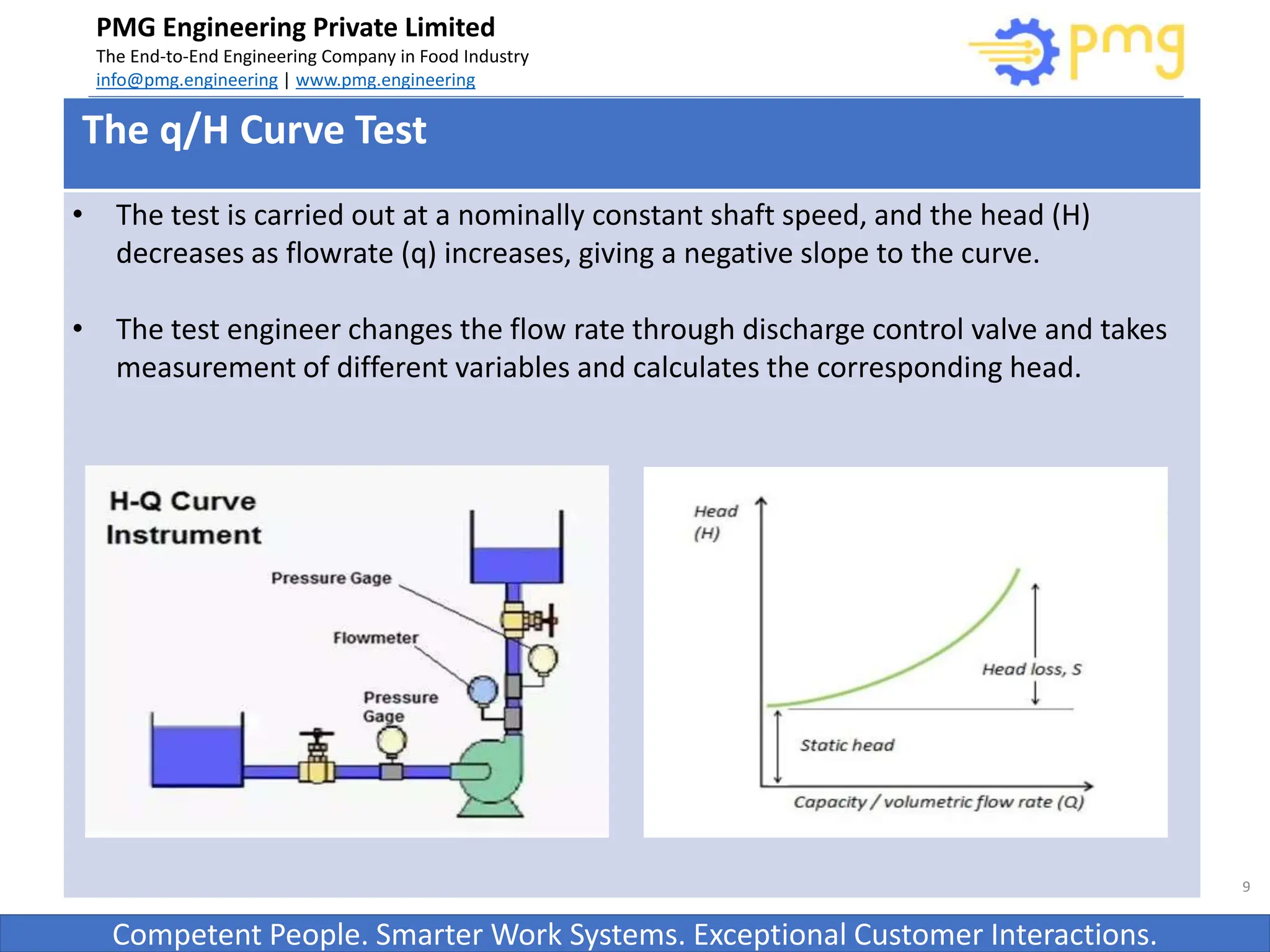

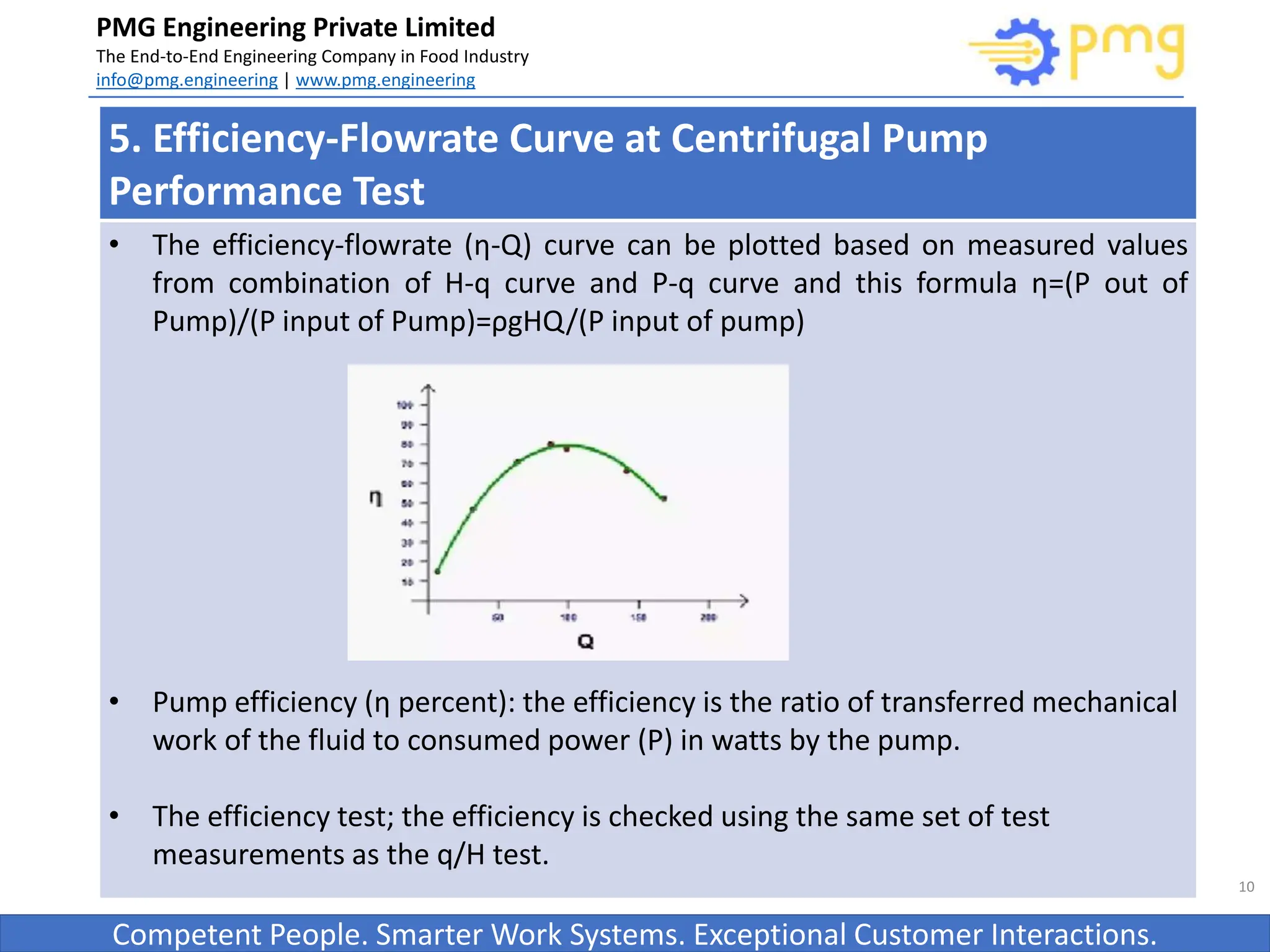

This document provides an overview of centrifugal pumps, detailing their function, performance parameters, and the significance of flow rate and head. Key aspects include the importance of efficiency, power consumption, and the characteristics that affect pump performance, such as viscosity and operating pressure. It concludes with guidance on selecting the right pump based on system requirements and highlights potential energy savings from optimizing flow rates.