This document is an internship report on hand block printing completed by Harsha Goplani at Gaura Textile Studio in Bhopal, India. It provides details about the studio owner Gaura Joshi and her background in textile design. The objectives of the internship were to learn block printing techniques and develop products. Key aspects covered include the history of block printing in India, types of blocks, the printing process, and photos of products developed during the internship like table covers, bed linens, and cushion covers.

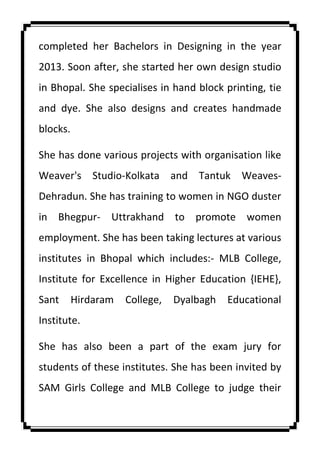

![ORGANISATION STRUCTURE:-

PRODUCTS DEVELOPED:-

1.Table cover

2.Silk fabric for shirt.

3.Bed linen consisting 1 single bed sheet, 1double

bed-sheet [Bombay dyeing].

4.6 pieces of cushion covers and 4-pillow covers.

5.Duvet covers 1 for single bed and 1 for double

bed.

Gaura Joshi

[head]

Deepa didi

[store

manager]

Intern

A

Intern

B

Lalit bhaiya

[ printing

expert]

Intern

C](https://image.slidesharecdn.com/gaurainternshipdocumentation-190314164749/85/Gaura-internship-documentation-13-320.jpg)