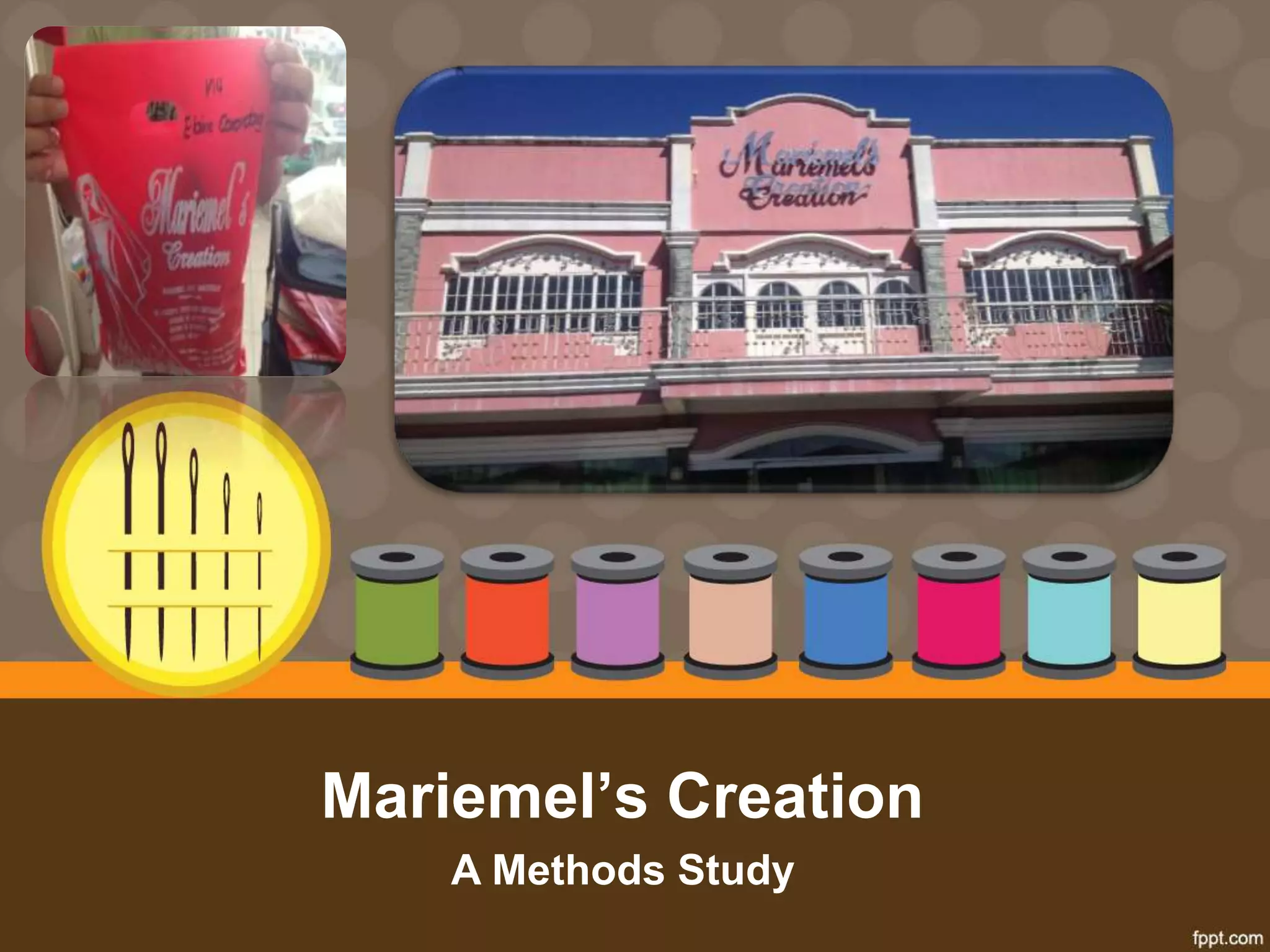

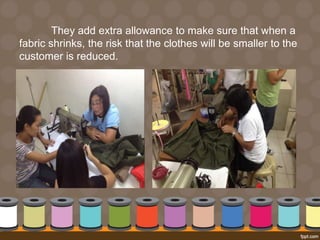

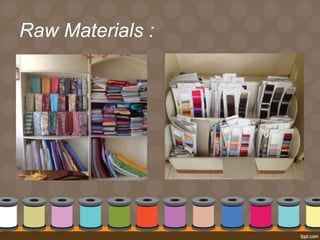

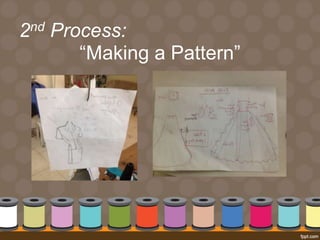

Mariemel's Creation is a dressmaking business that follows a standard process for all products. They measure, make patterns, cut fabric, sew the pieces together, and finish the items with ironing and attaching buttons. While challenging at first to fulfill custom designs, they strive to meet deadlines. Their operations cannot be reduced as each step is essential. Materials are ordered from trusted suppliers to ensure quality. The business stores fabrics systematically to reduce production time. Machines are used along with manual labor. While continually seeking efficiencies, they will not sacrifice quality for speed.