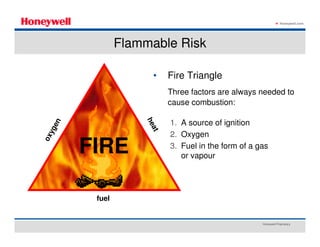

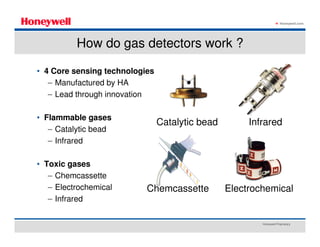

Honeywell Gas Detection specializes in designing and manufacturing gas detection equipment to safeguard personnel and facilities against flammable and toxic gas hazards, with applications in various industries including oil and gas. The document outlines the company's strengths, product offerings, and various gas detection technologies, emphasizing their commitment to safety and innovation. It also discusses the principles of gas detection, the types of gas hazards, and operational guidelines for effective monitoring and maintenance.