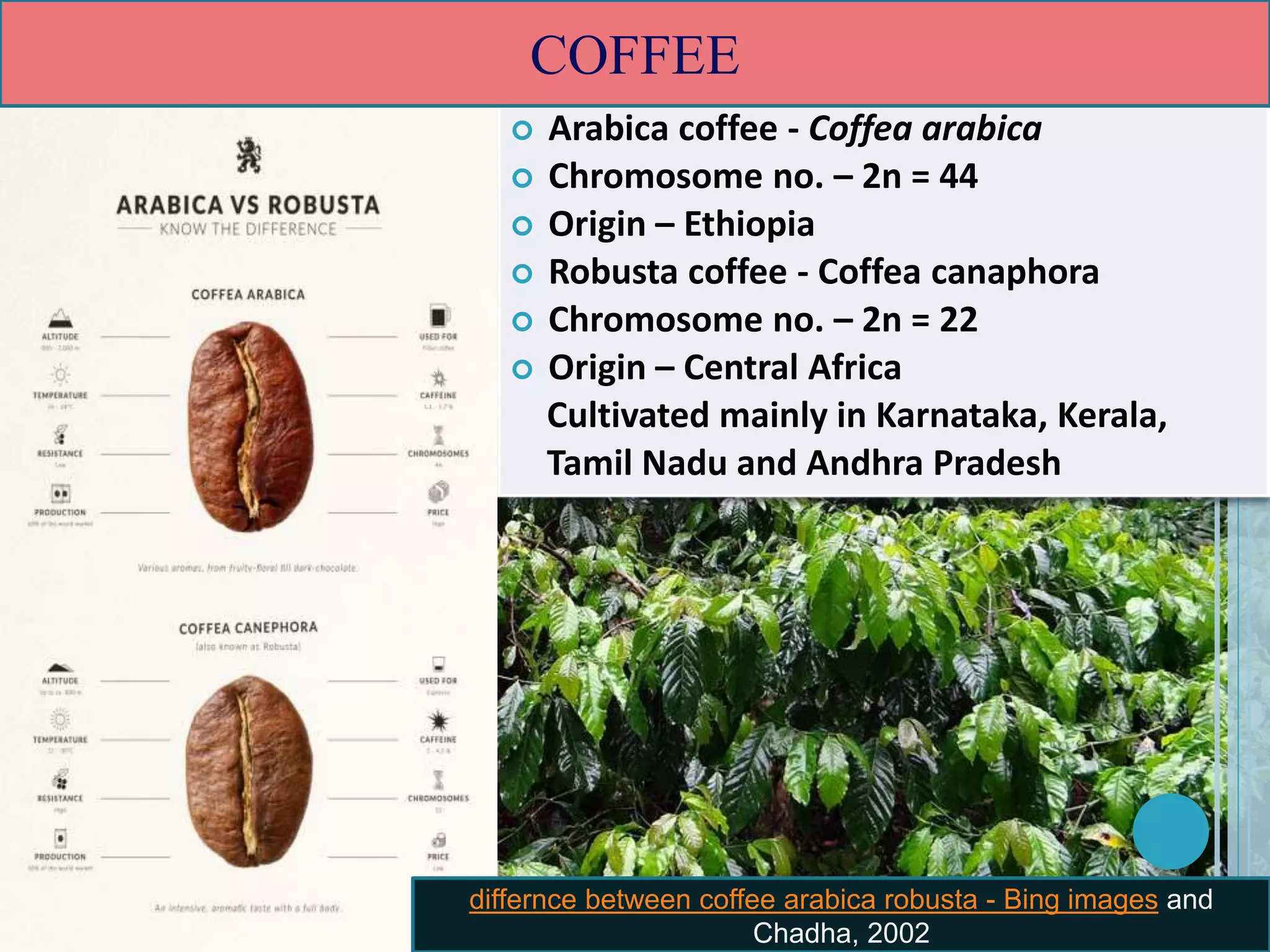

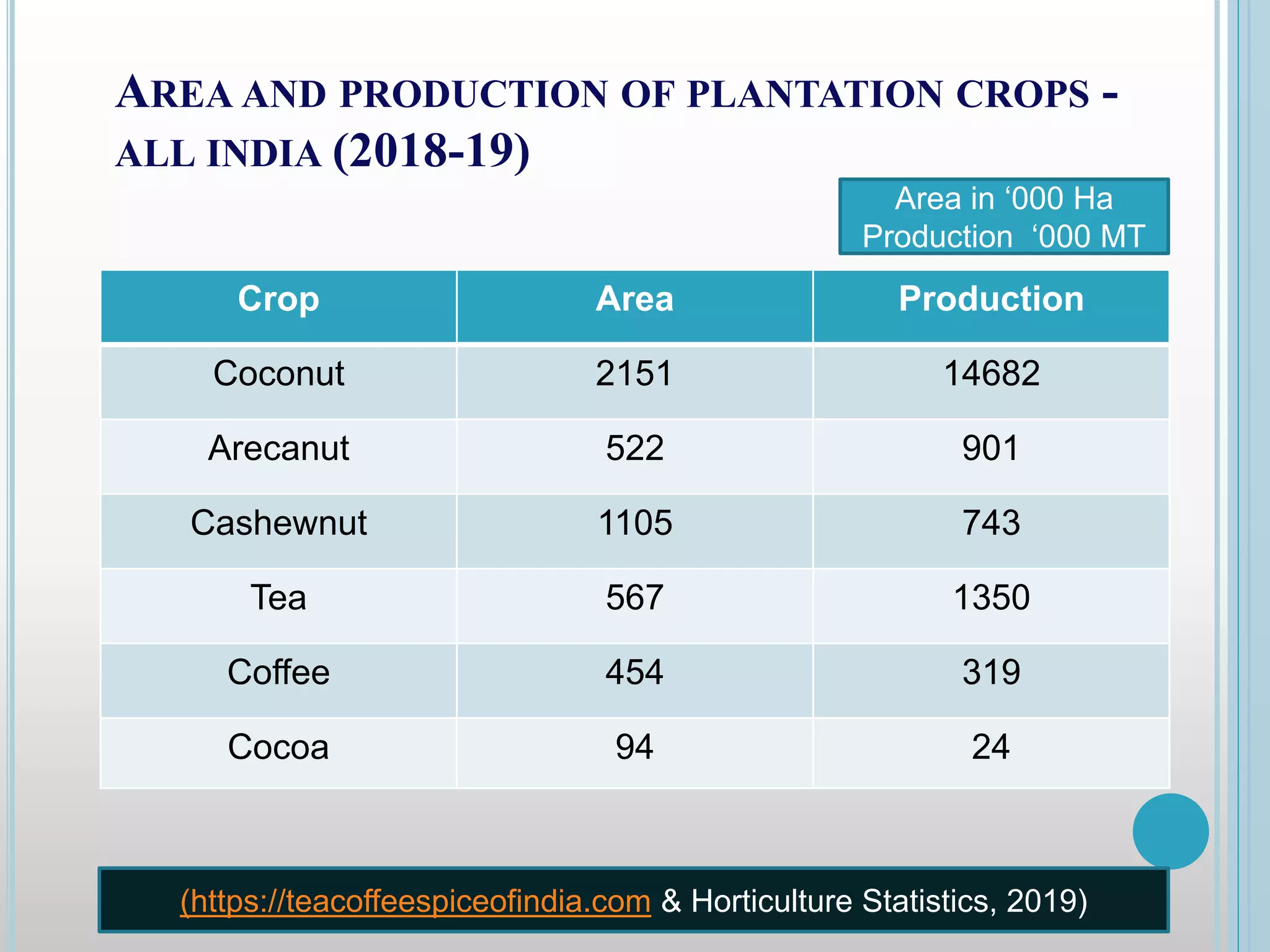

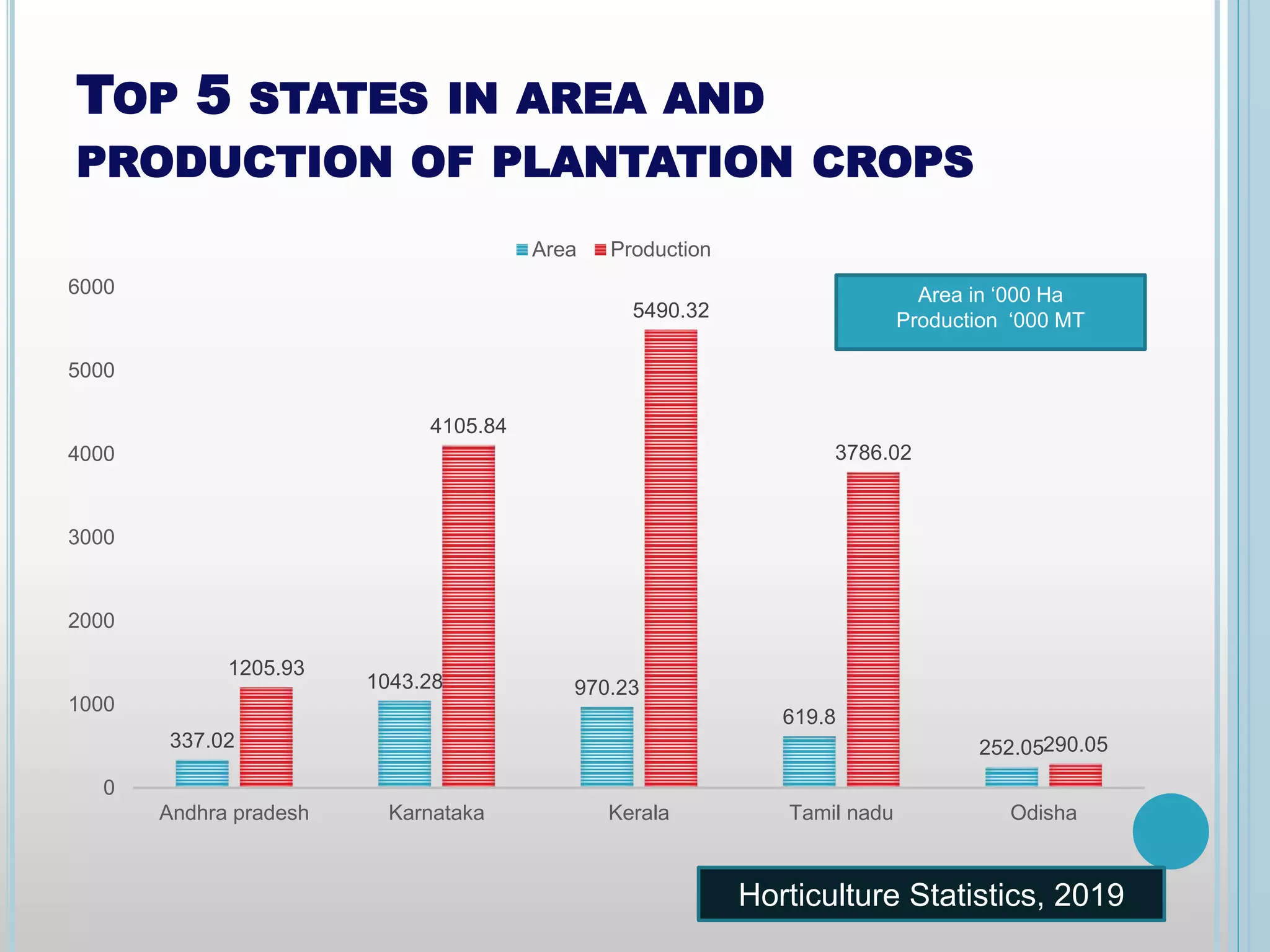

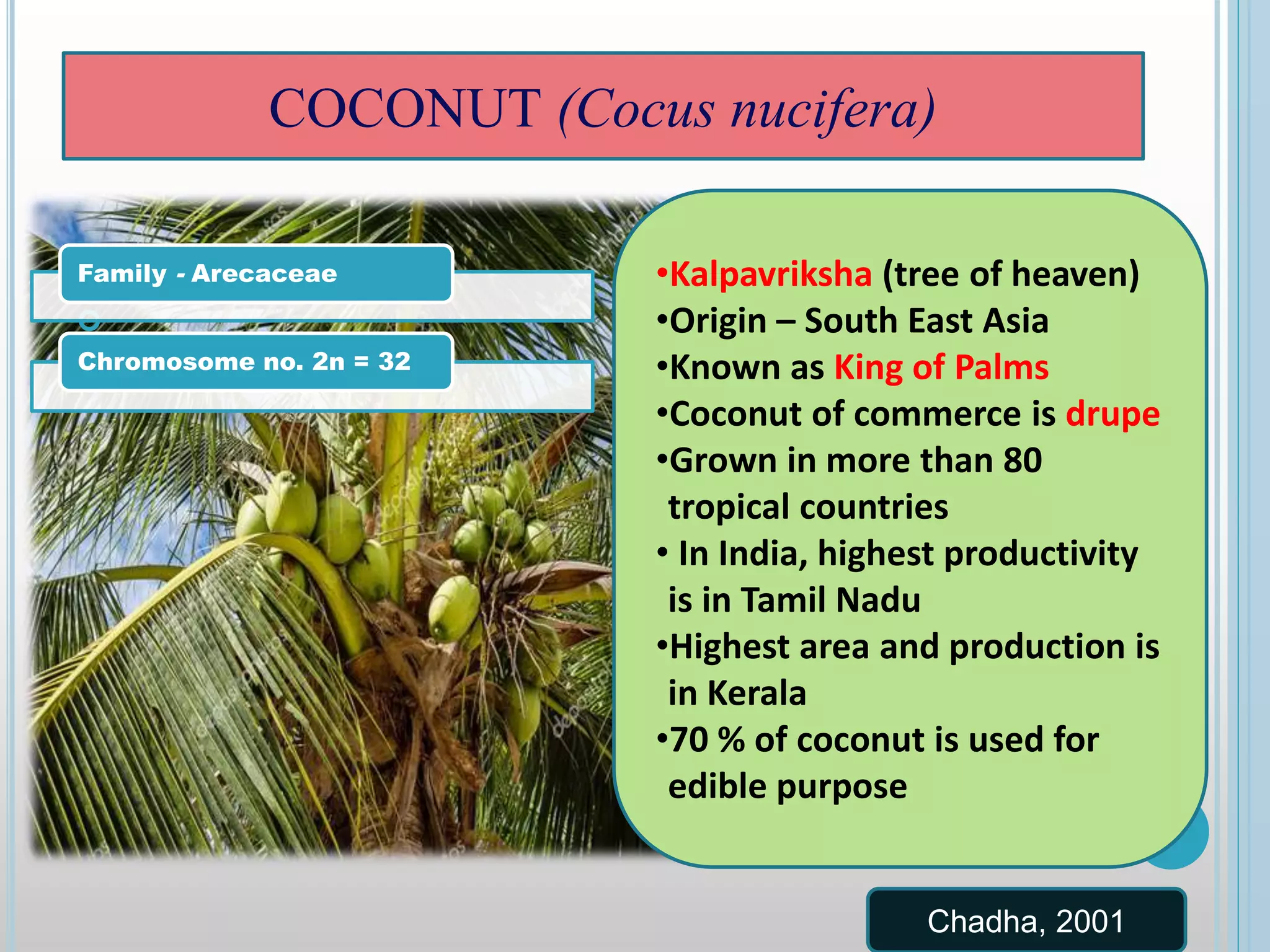

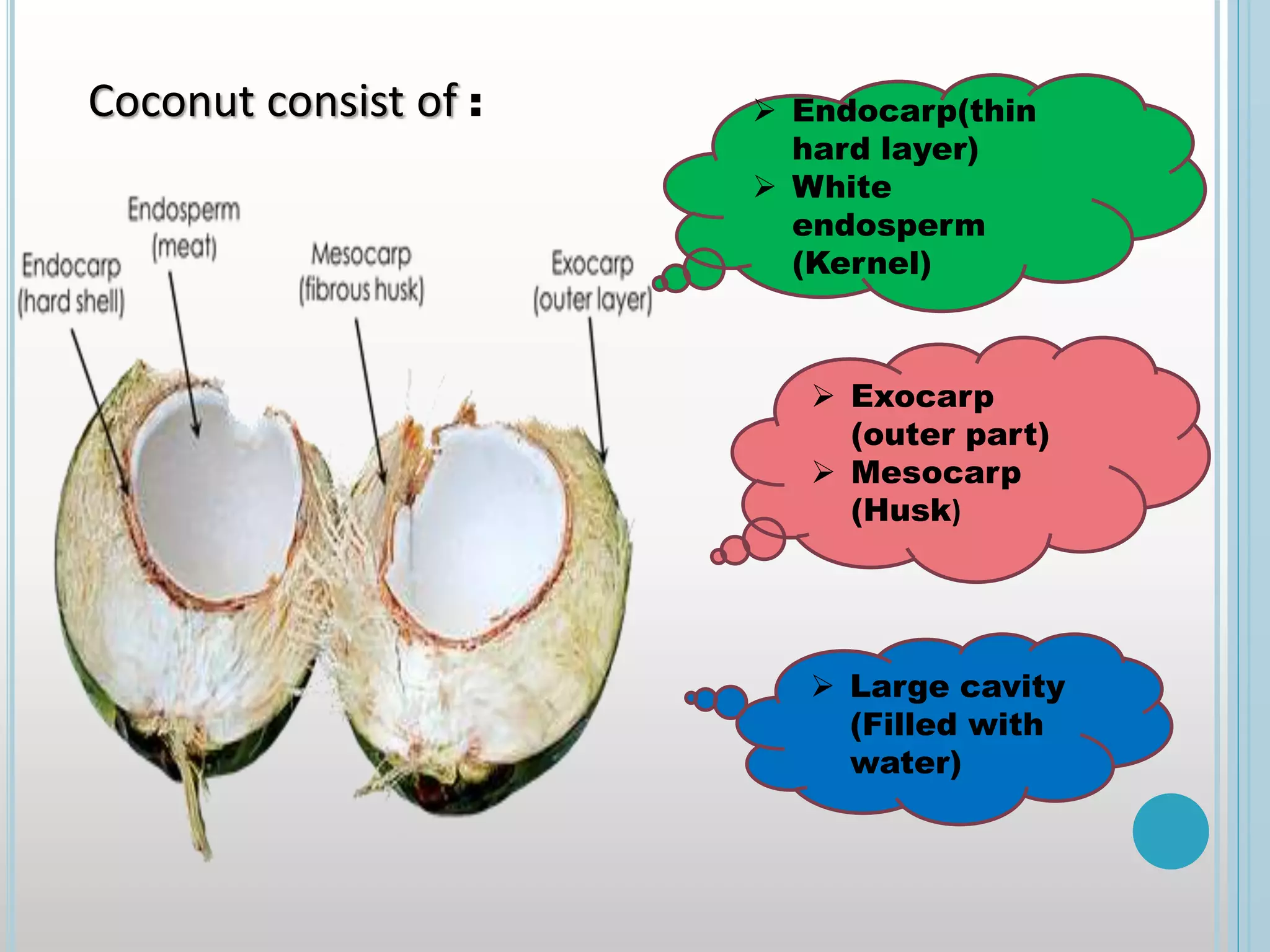

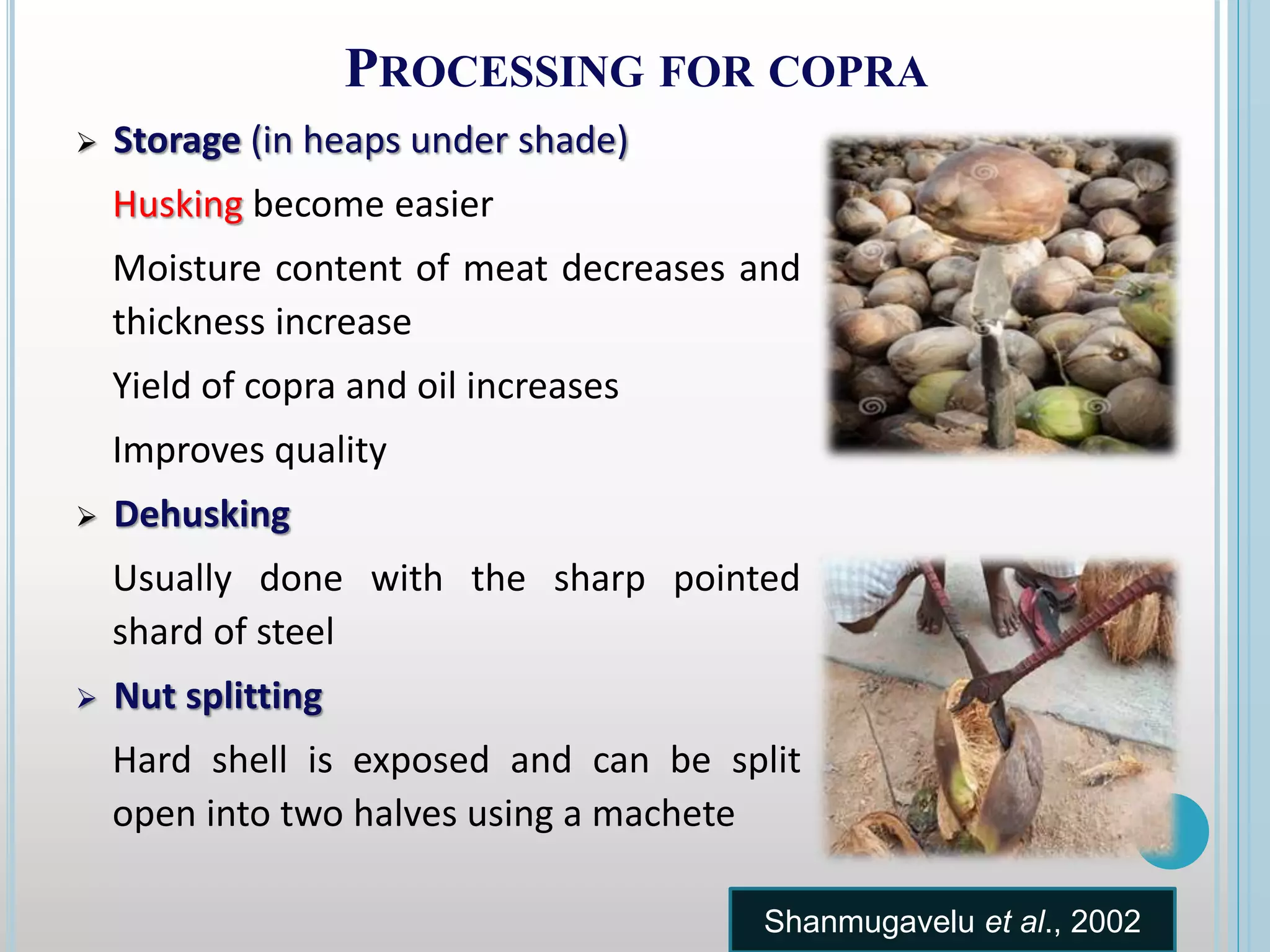

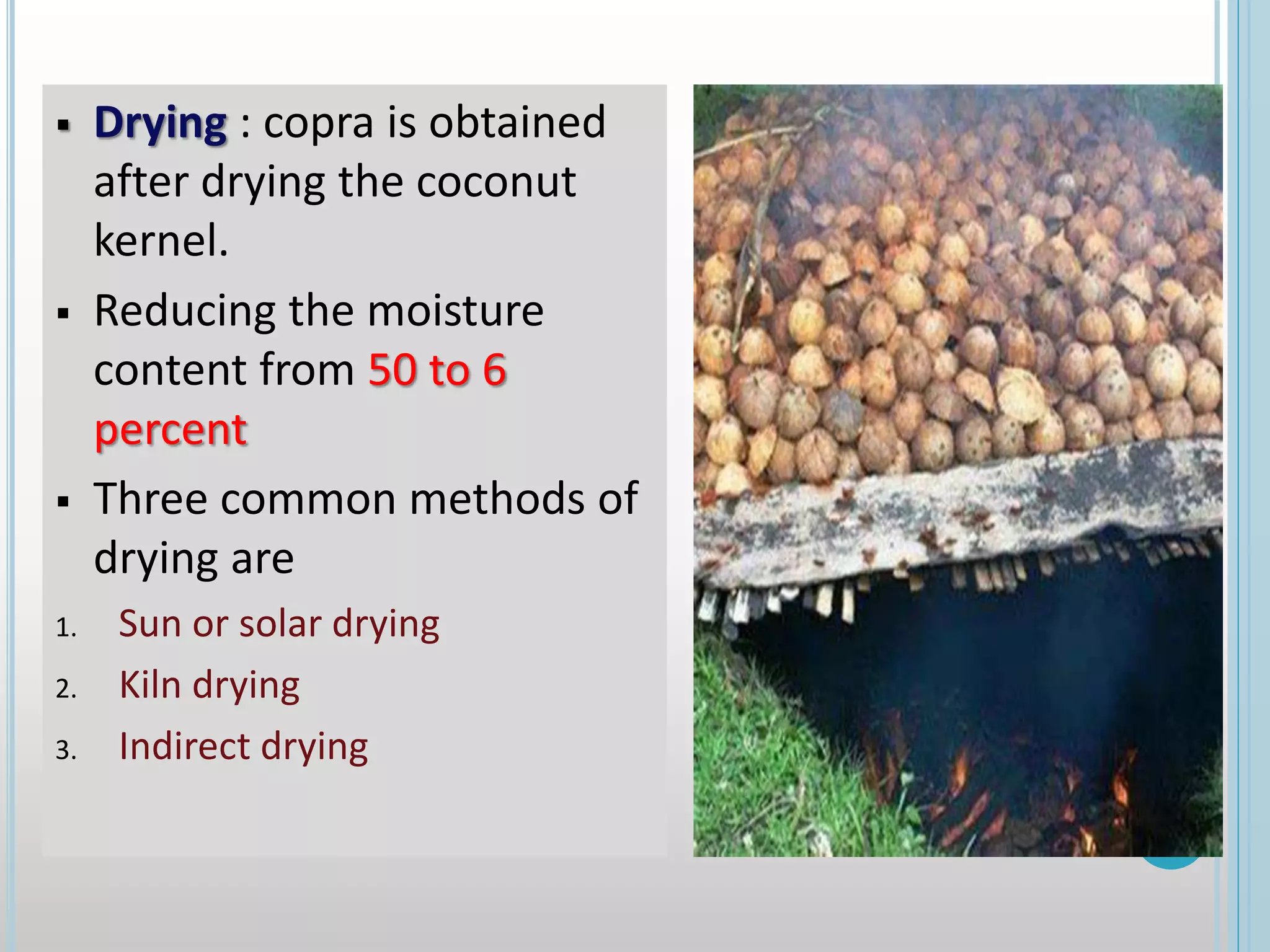

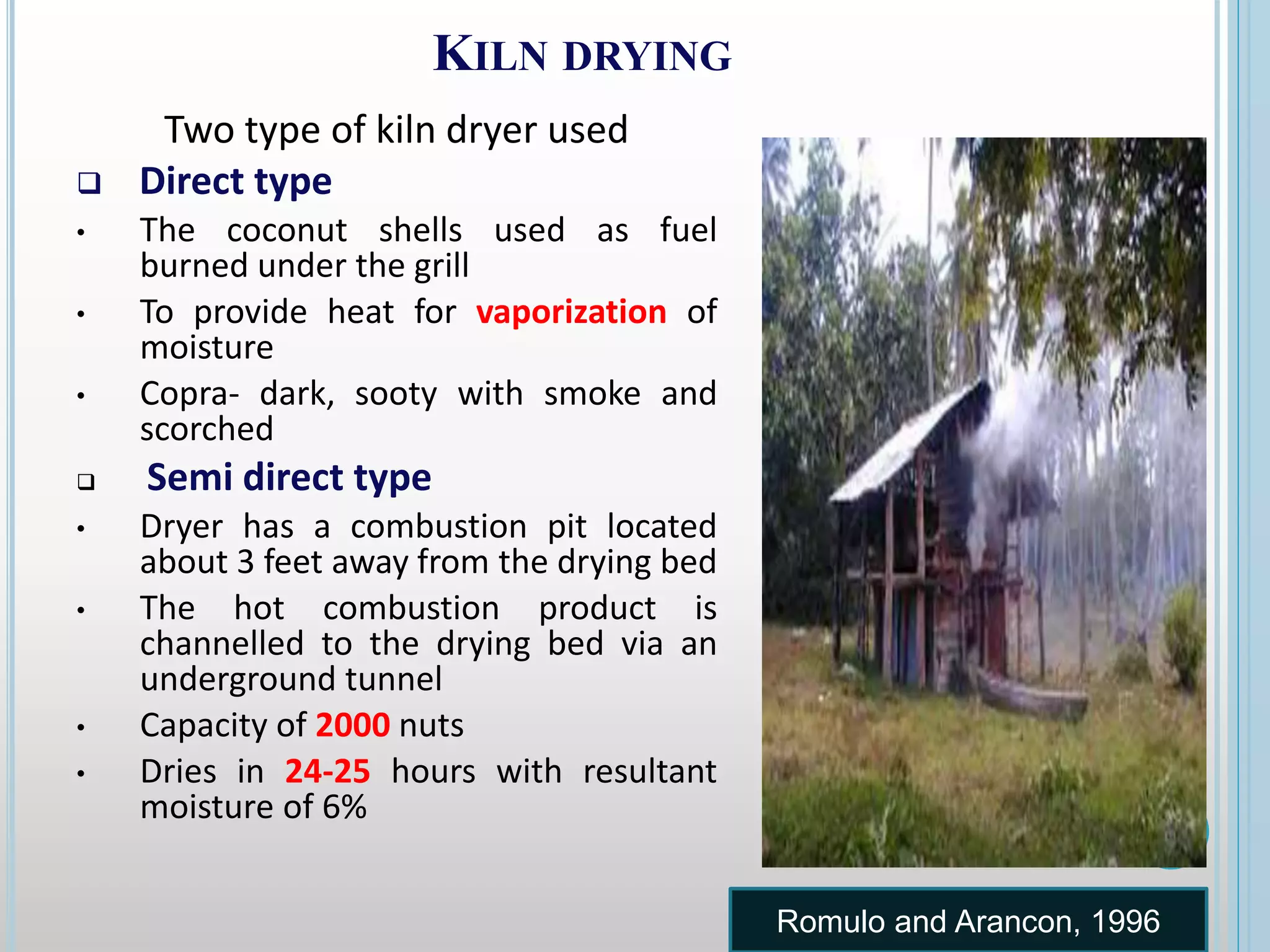

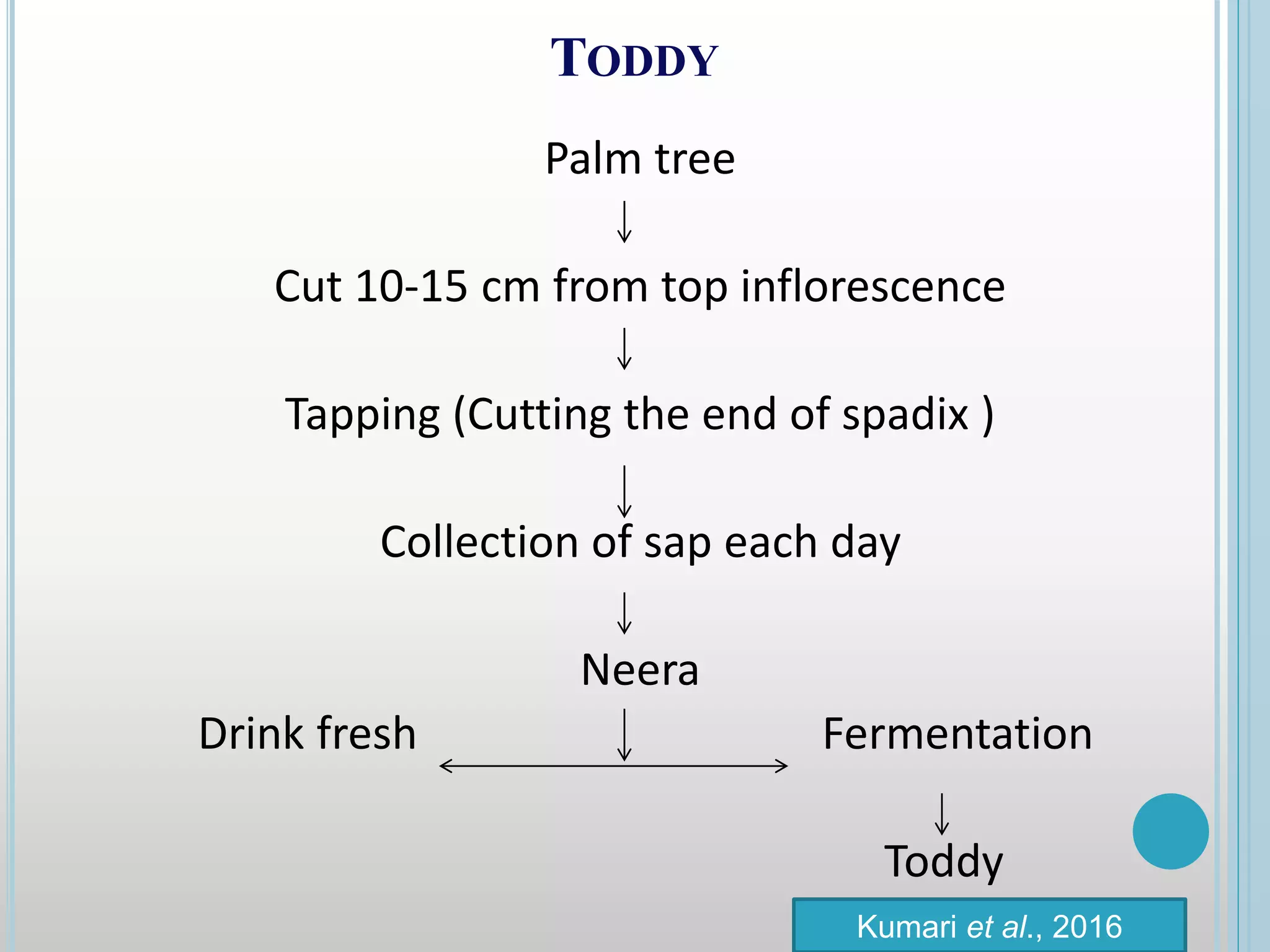

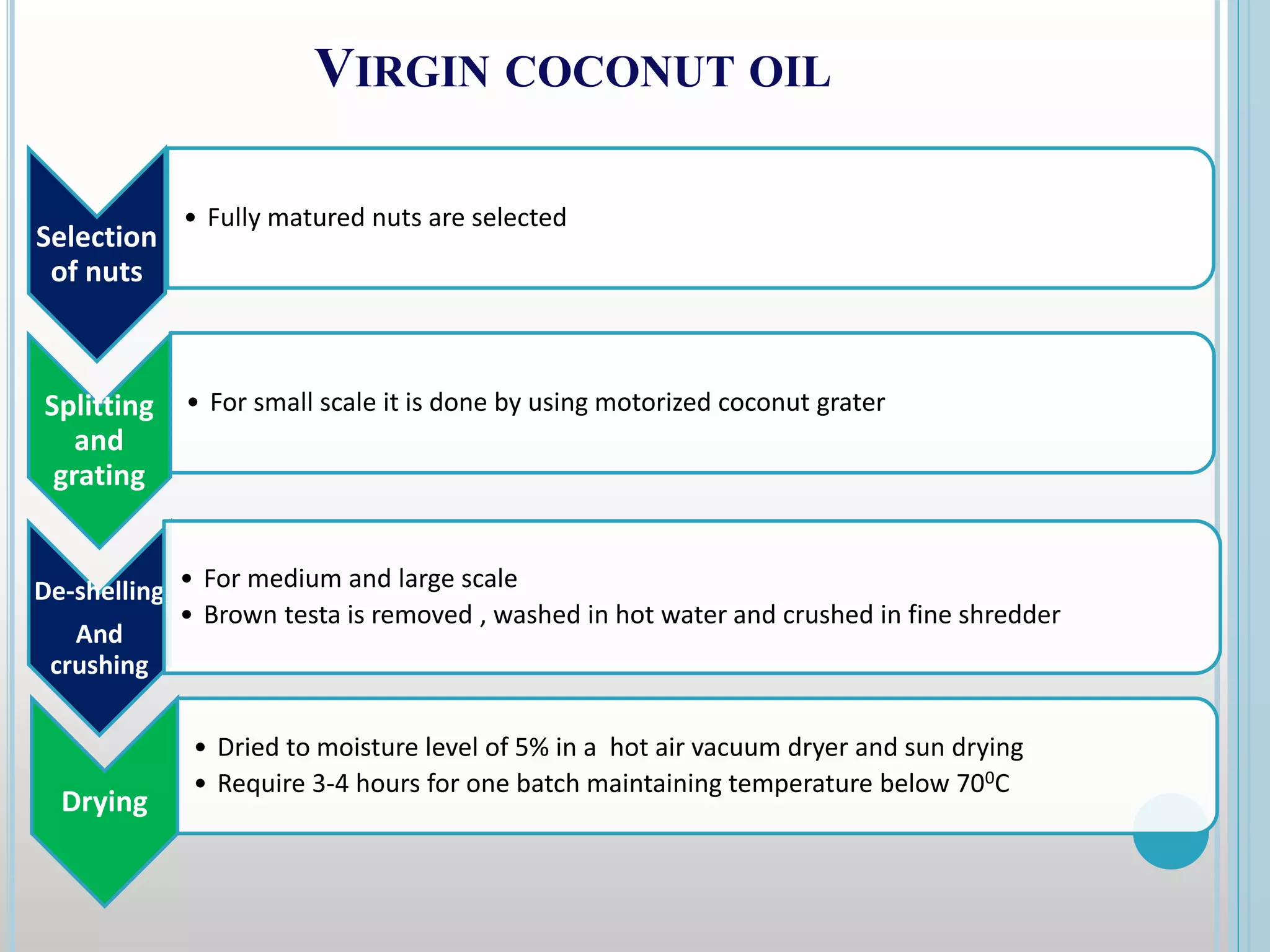

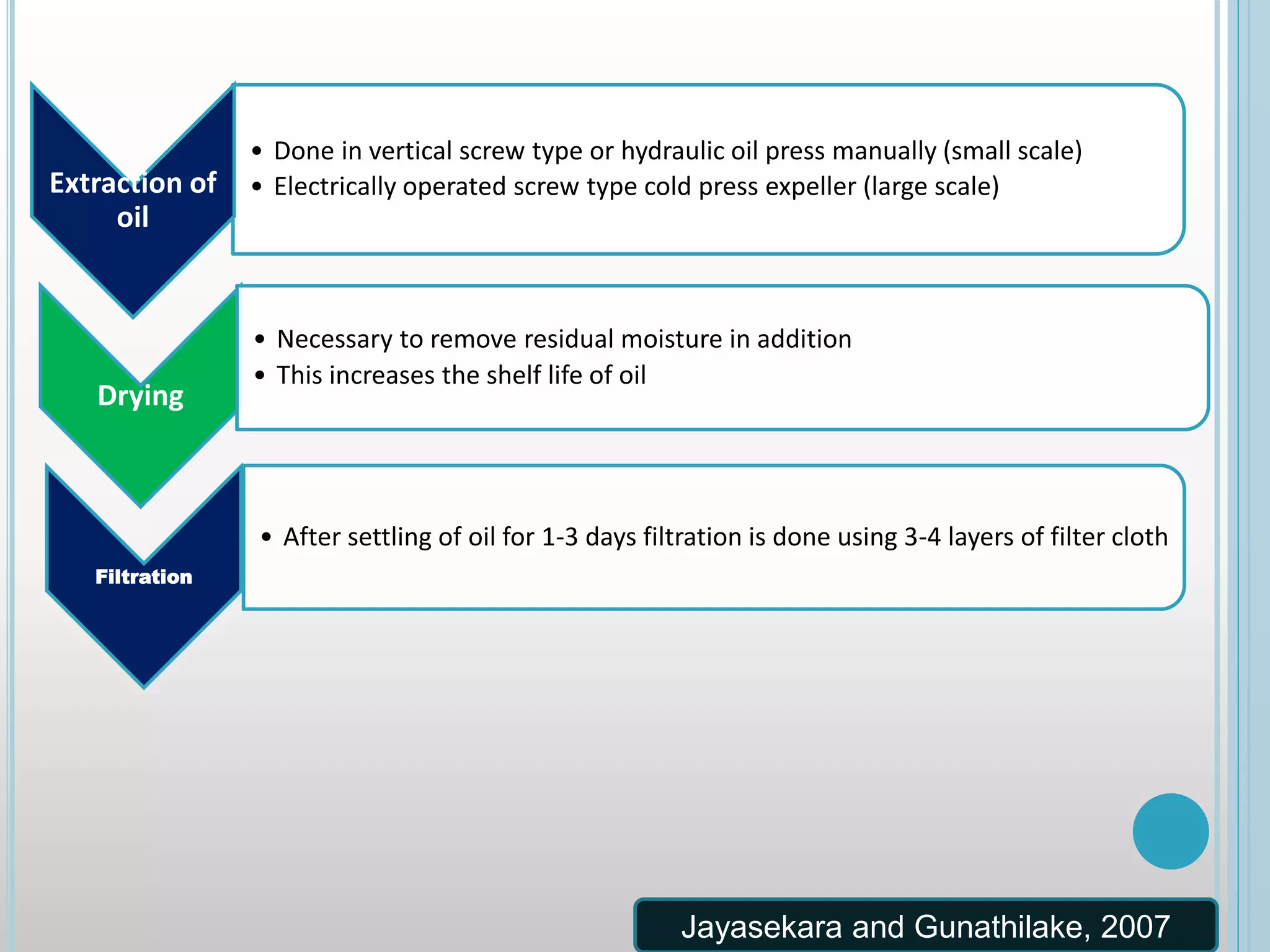

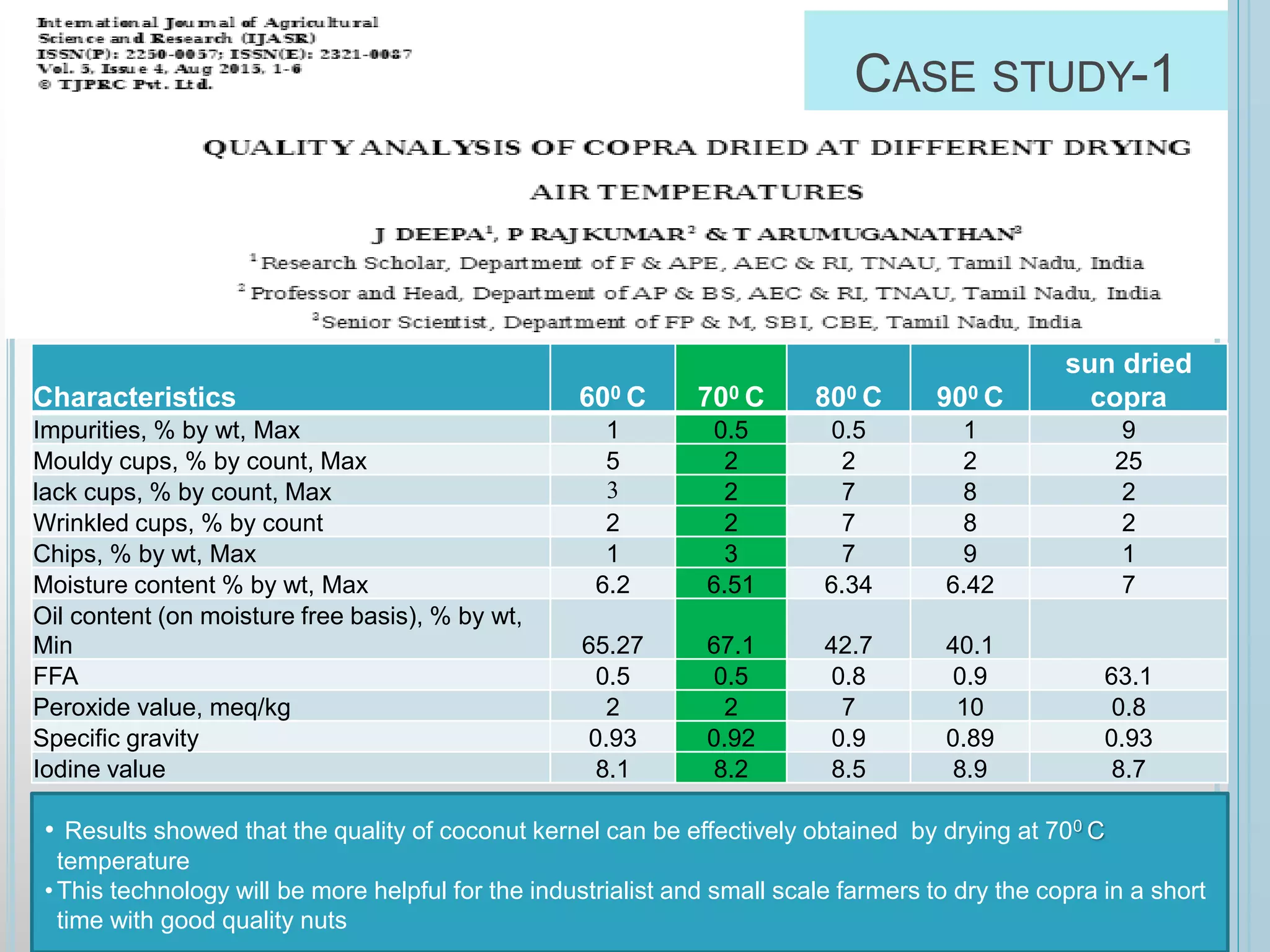

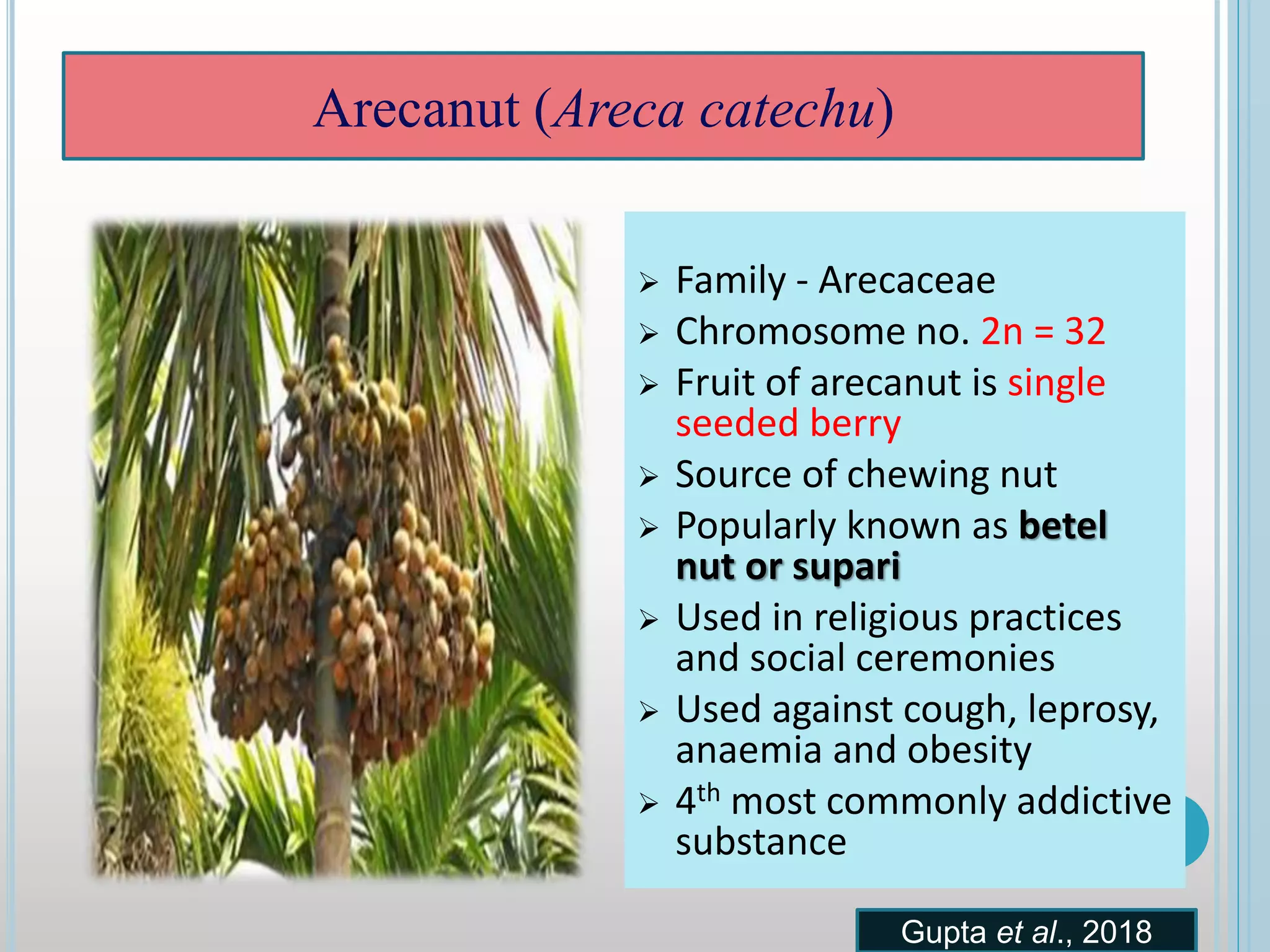

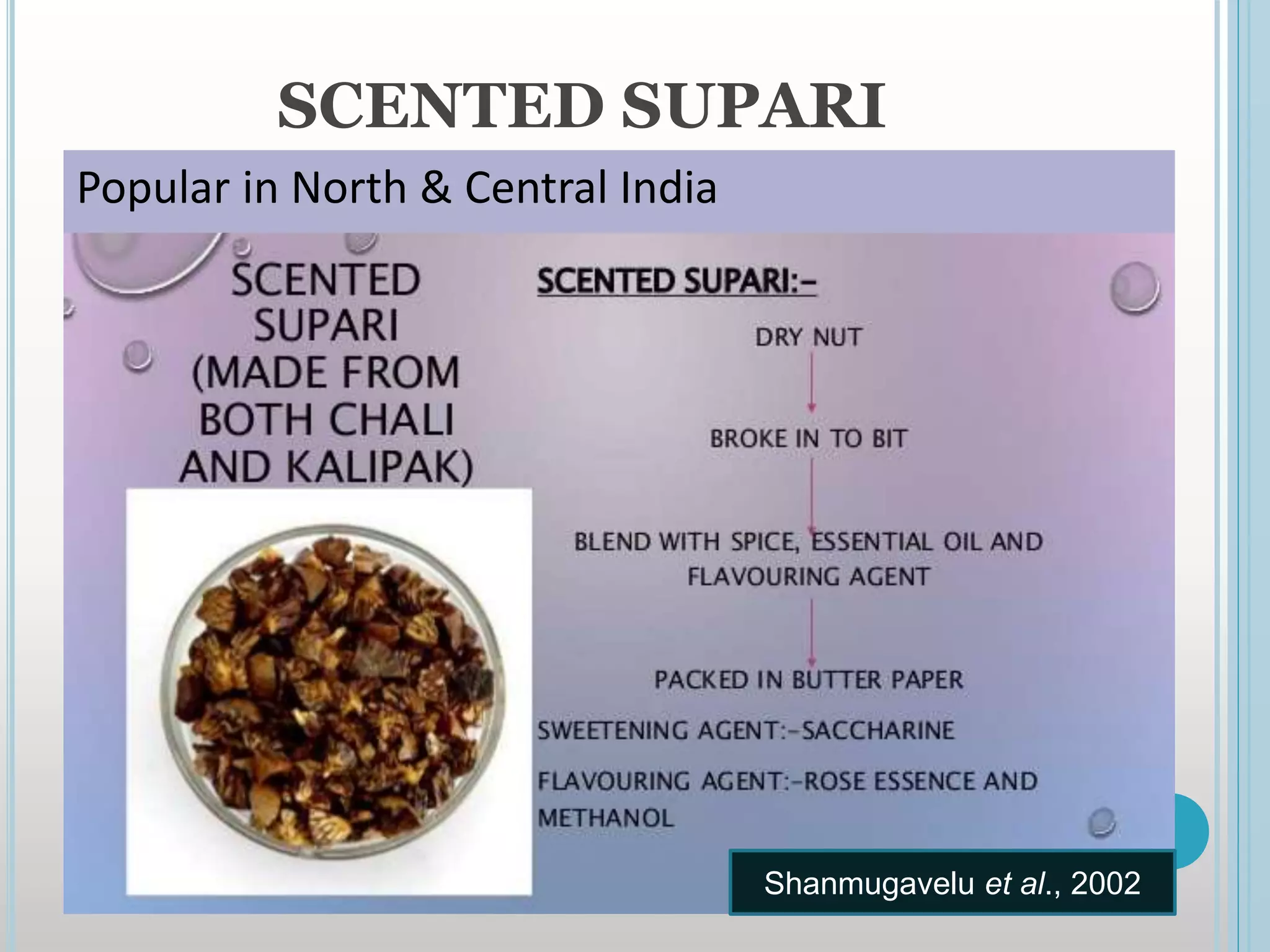

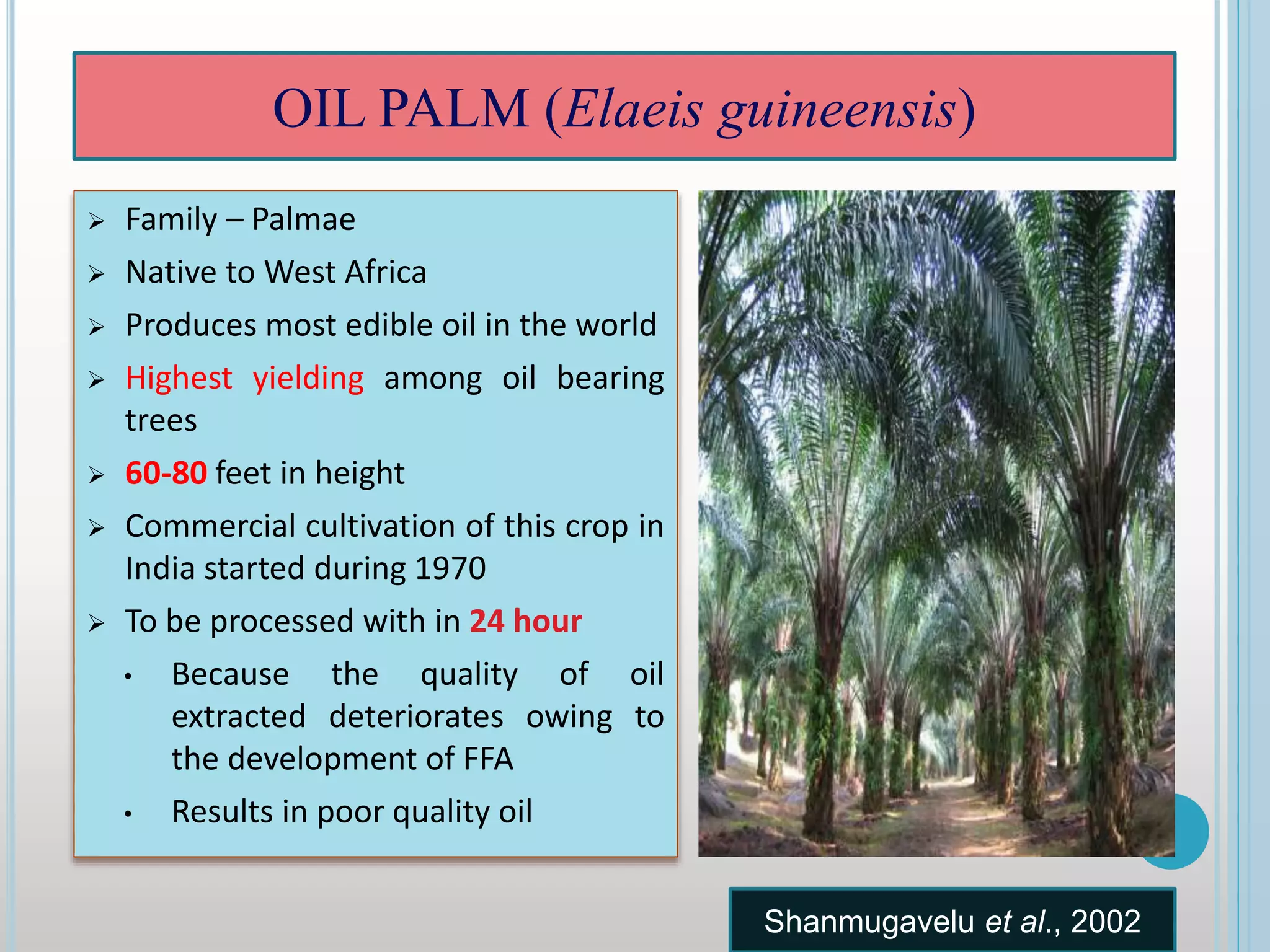

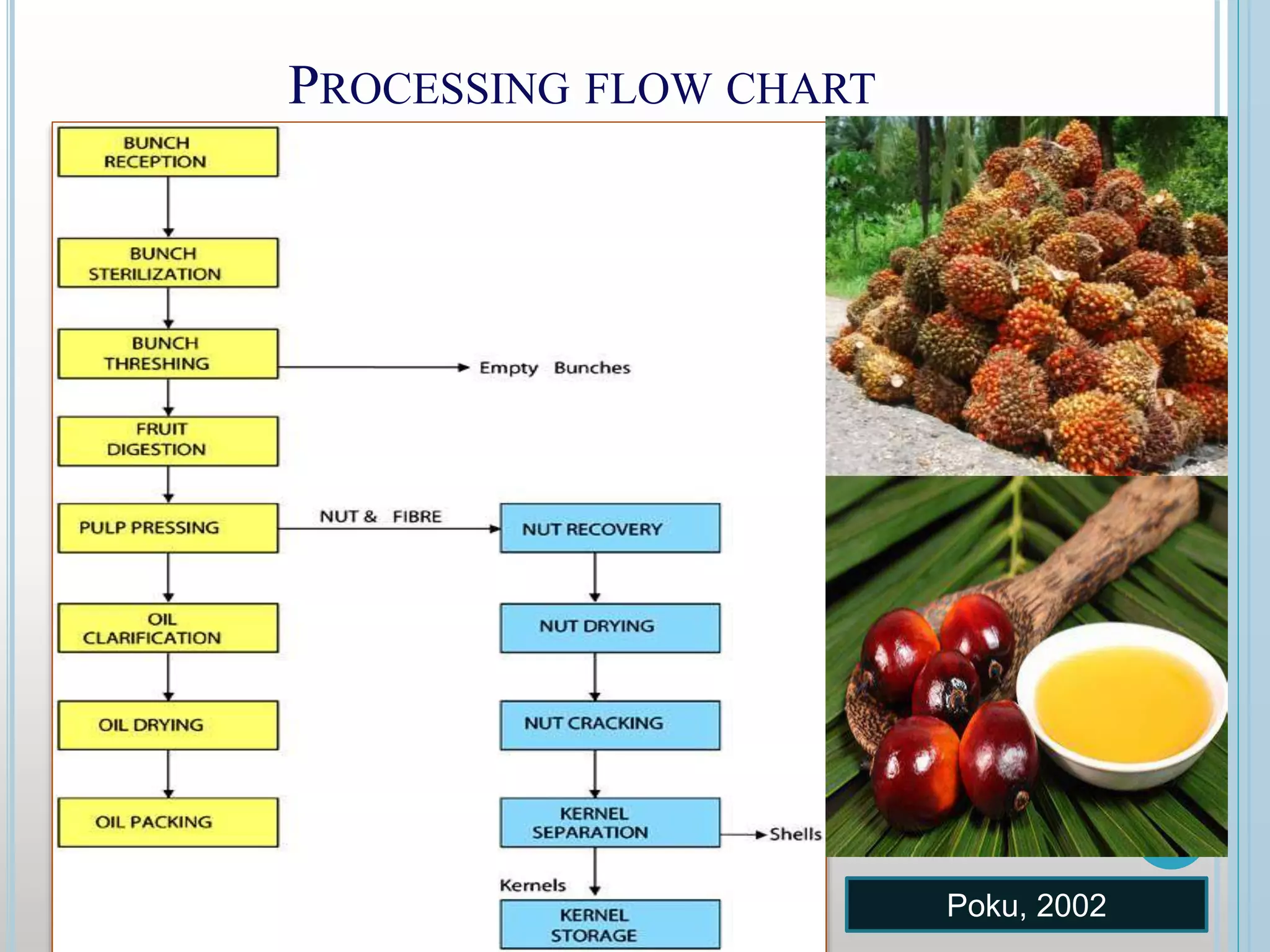

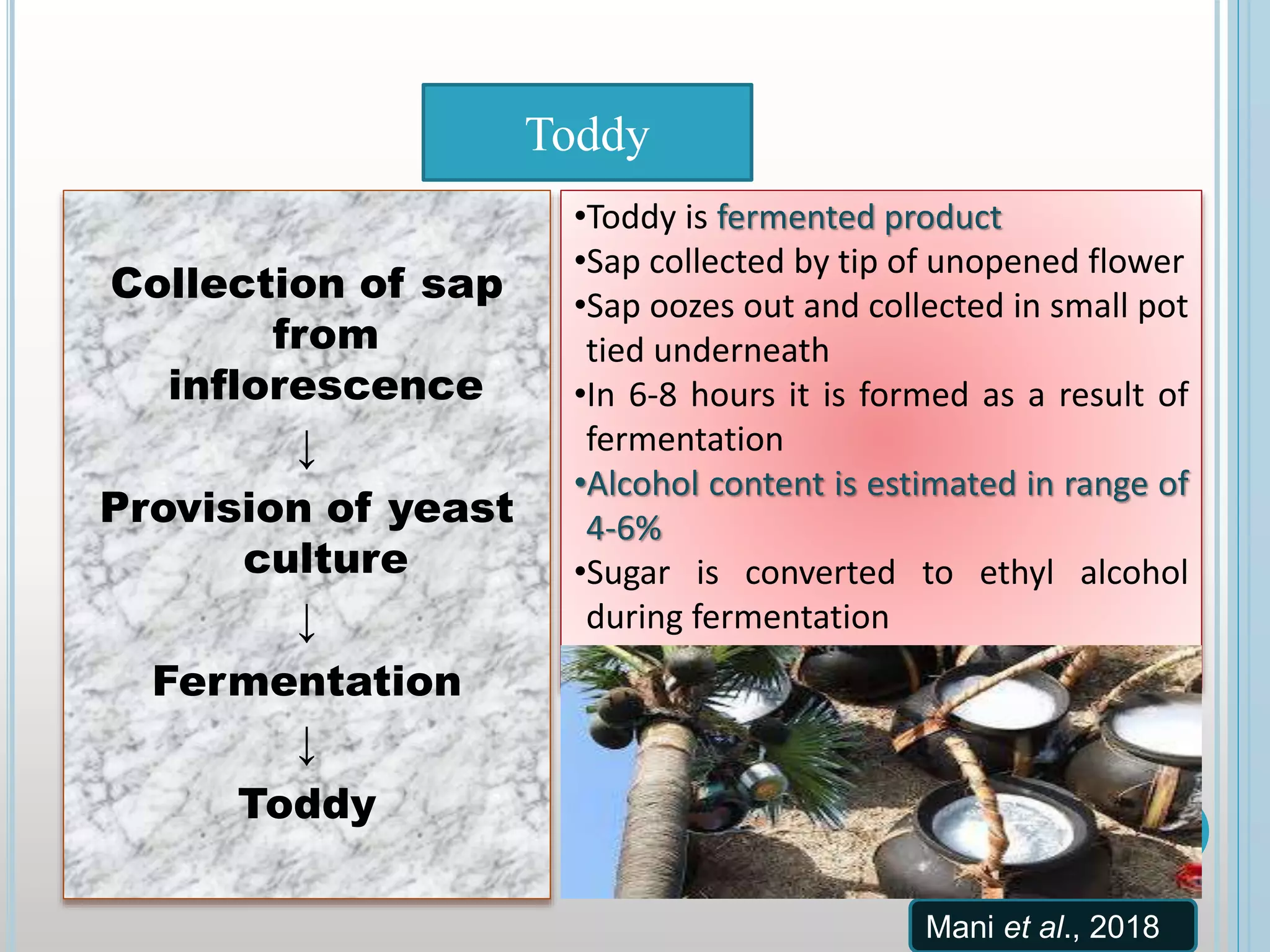

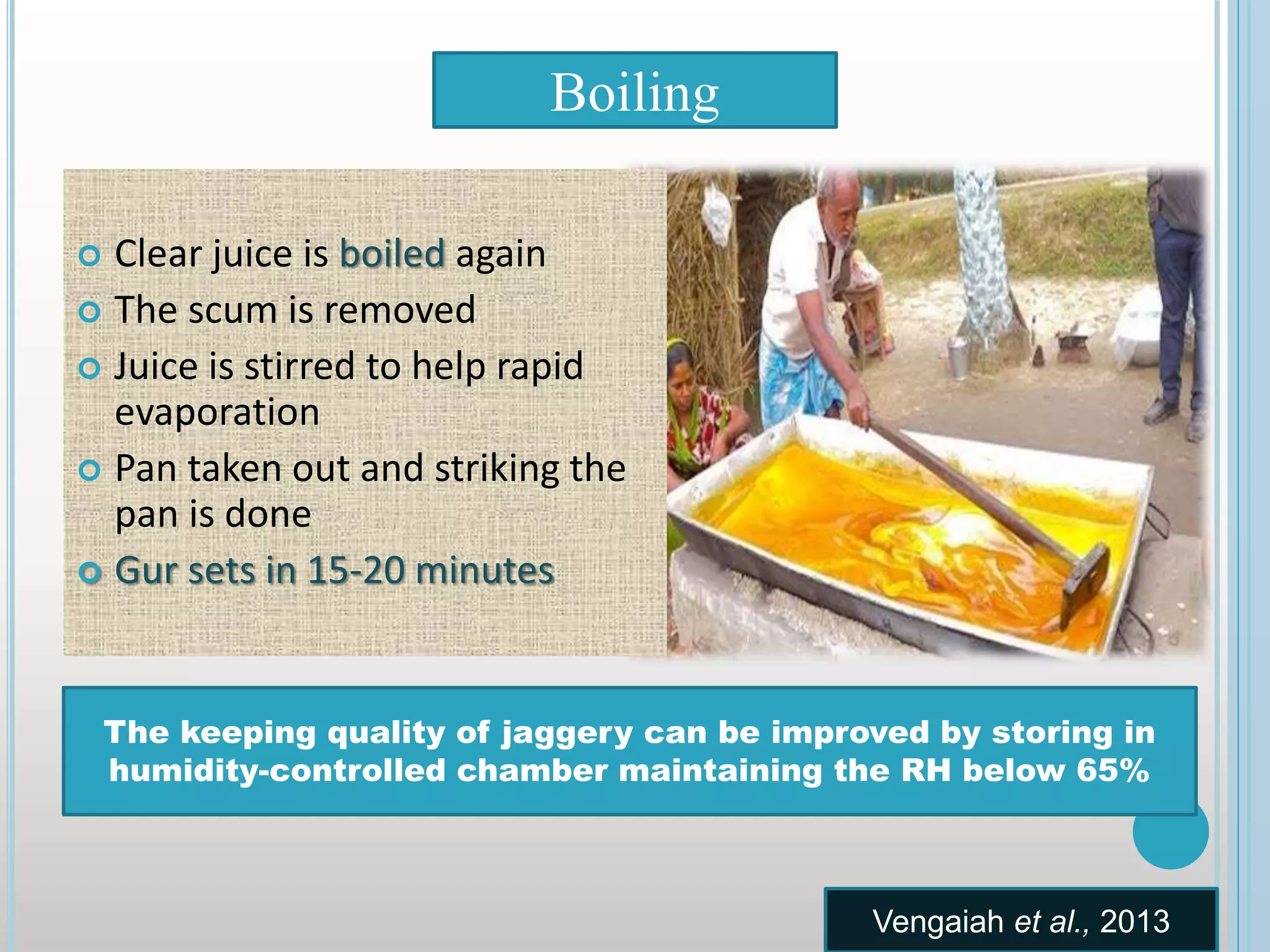

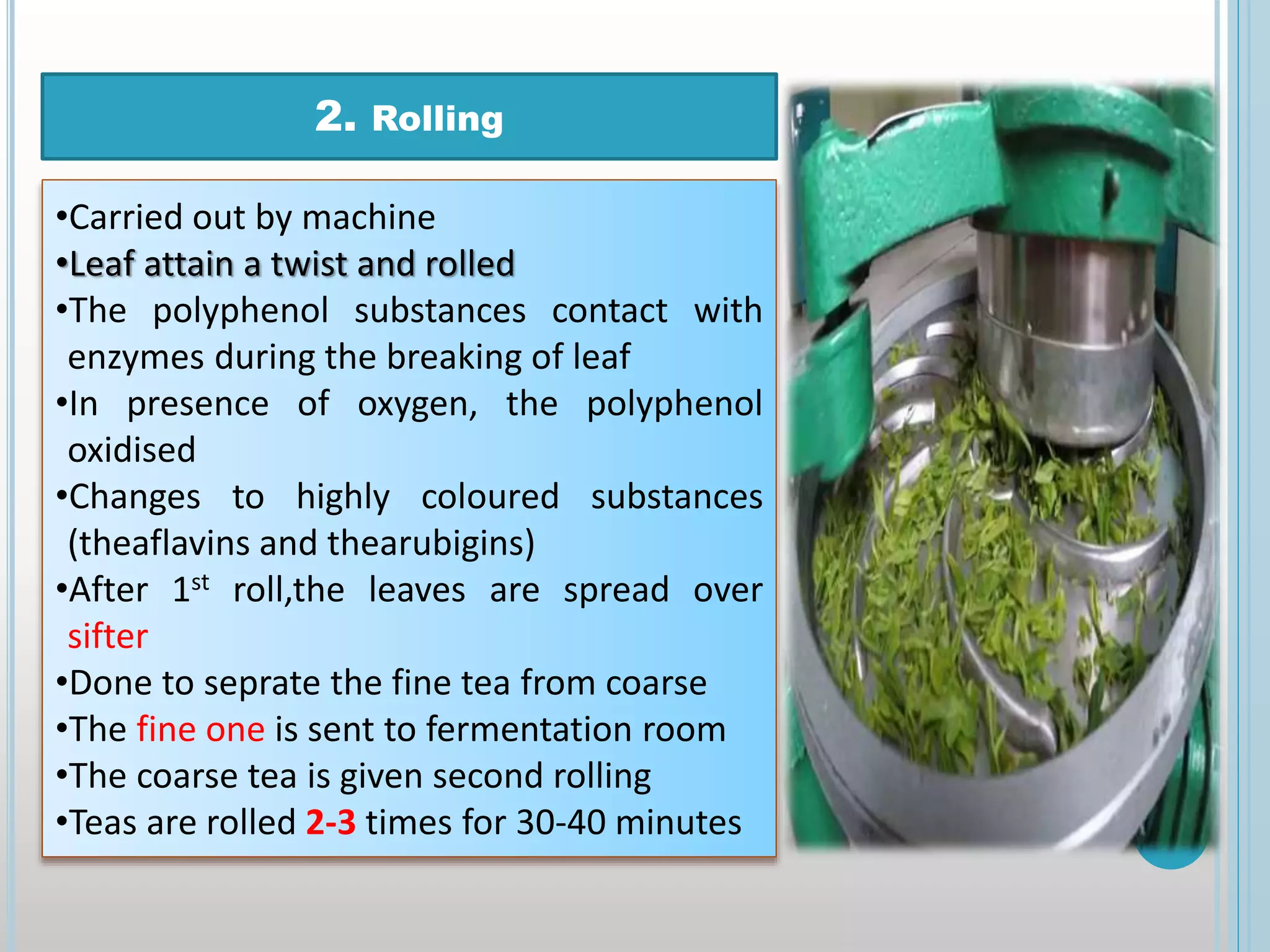

The document discusses various plantation crops grown in India including their processing methods. It provides area and production statistics for major crops like coconut, arecanut, cashewnut, tea, and coffee. For coconut, it describes the components and different processing steps to produce copra, coconut oil, and other products. Similar processing details are provided for arecanut and case studies on drying coconut kernels and developing a arecanut dehusking machine. Processing of palm products like neera, toddy and jaggery are also summarized along with a case study on palm jaggery preparation. The document concludes with a brief overview of tea processing steps.

![]

]

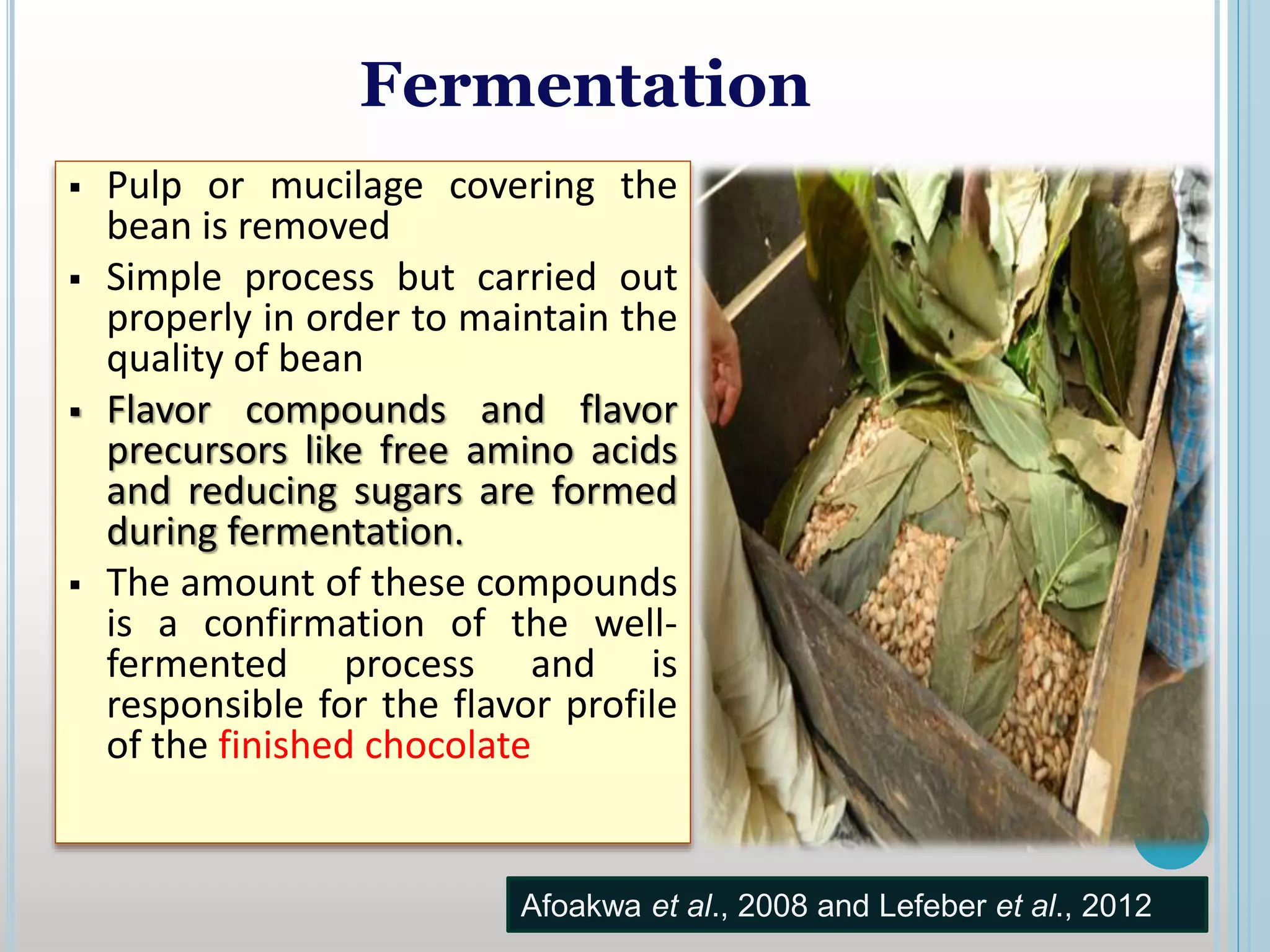

3. Fermentation

•Leaves spread on concrete bed or

aluminium trays

•Fermentation vary from 1-3 hours

•Low humidity causes blackening of

leaf

•Usually tea growers judge it by

smelling, touching and feeling

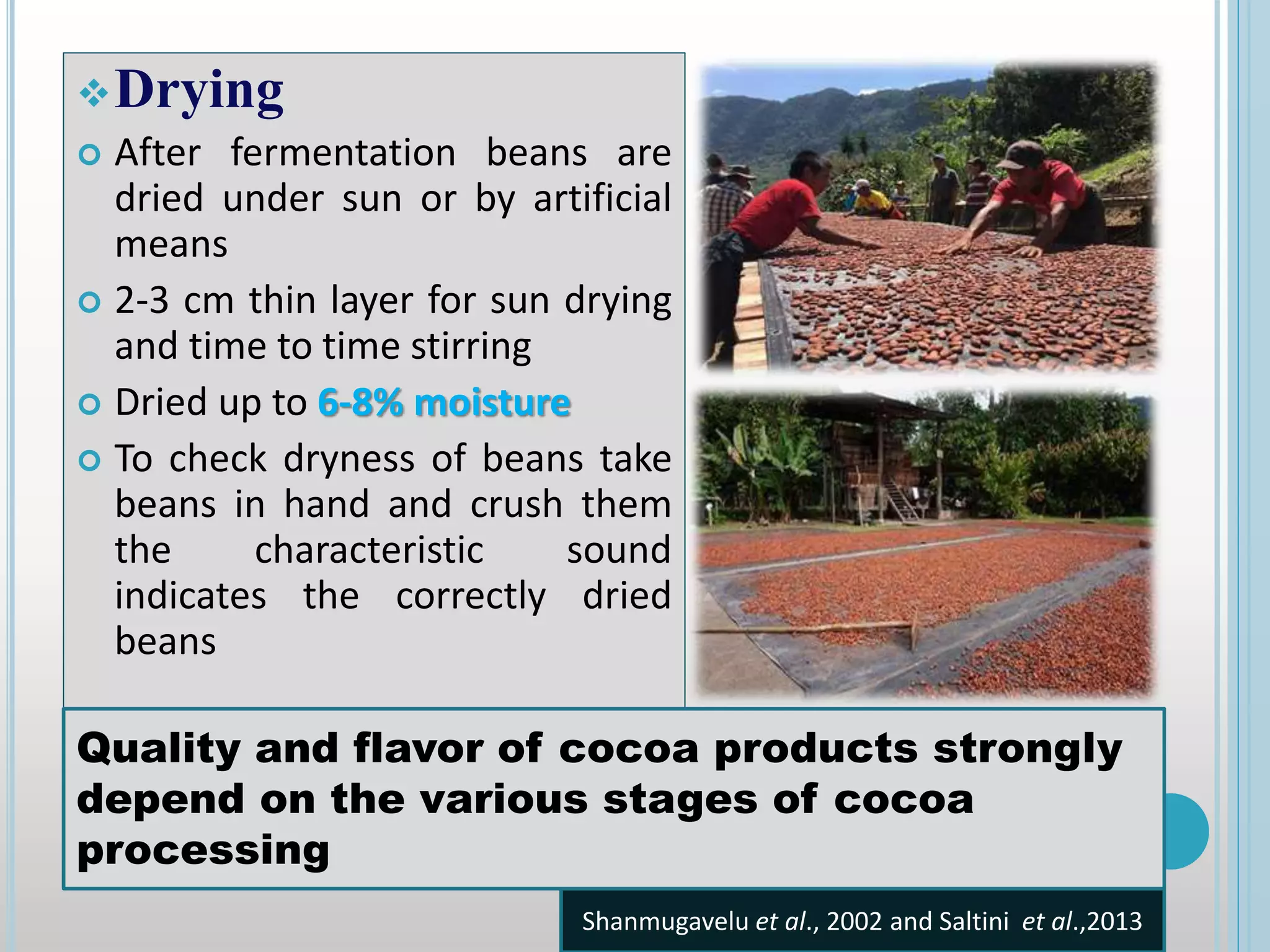

4. Drying

•Undergoes a process of drying in oven

called as ‘driers’

•136-1550 C initially then reduced to

1050 C

•Leaves are dried for 30-40 minutes

•Final drying done at 73.750 C before

packing

Shanmugavelu et al., 2002](https://image.slidesharecdn.com/sahilsmasterseminar-210204082153/75/Quality-and-Processing-of-Plantation-crops-38-2048.jpg)