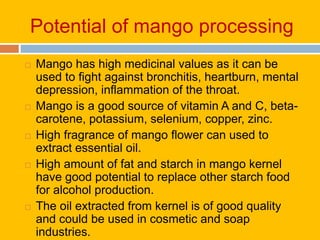

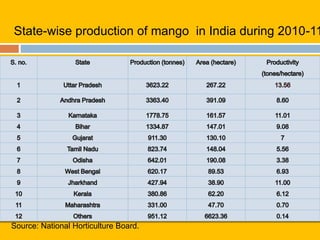

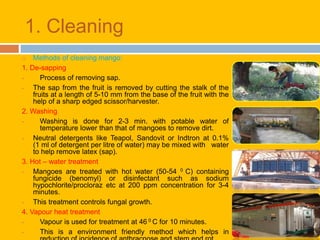

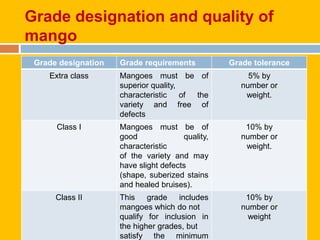

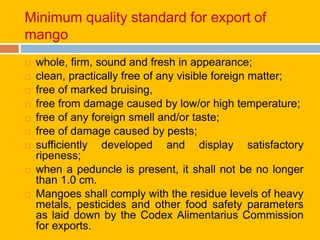

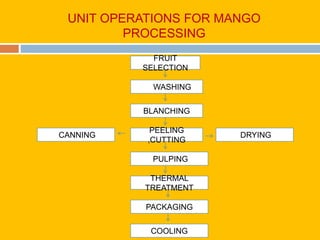

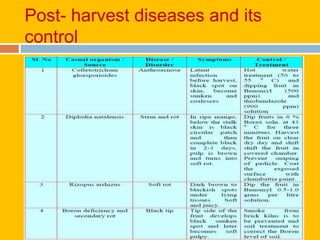

This document discusses the present status and future potential of post-harvest processing of mangoes in India. It provides details on mango production in India, common post-harvest operations like cleaning, sorting, packaging and storage. It also describes value-added mango products and the various unit operations involved in mango processing. The document discusses utilization of mango by-products and some problems faced by the mango industry in India. It highlights the potential of mango processing given the various health benefits and uses of mango and its by-products.

![By-product utilization

Waste from

mango

processing

plant

PEEL(7-24%)

[pectin, biogas,

alcohol,]

KERNEL(9-40%)

[oil, tannis, flour]

POMACE (5-

10%)

[juice,wine,

vinegar]](https://image.slidesharecdn.com/phtonmango-170407132309/85/Pht-on-mango-28-320.jpg)