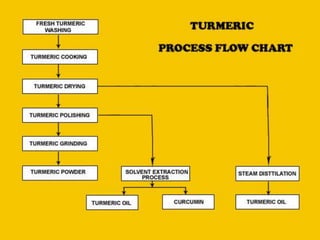

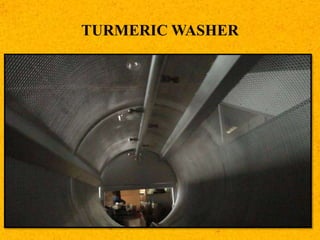

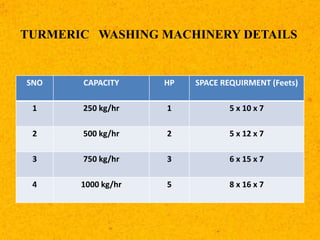

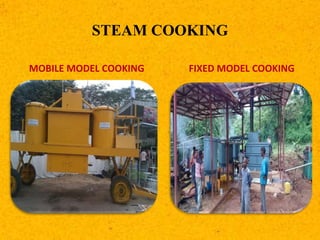

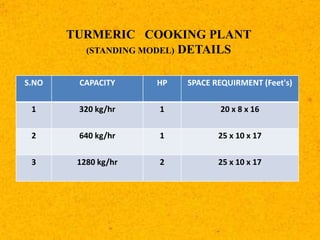

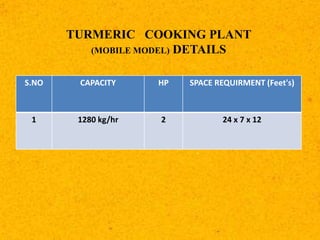

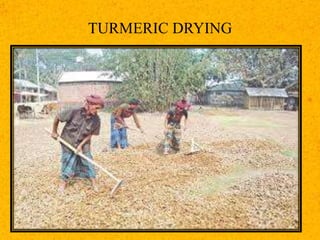

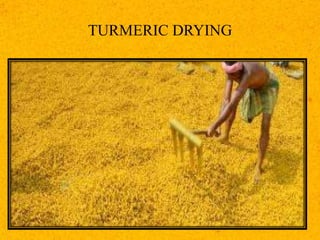

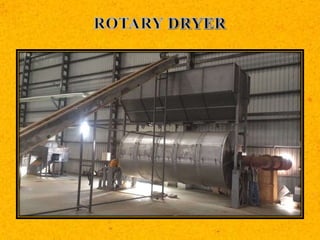

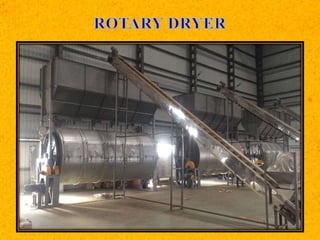

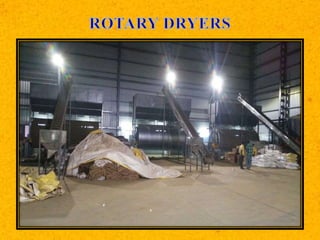

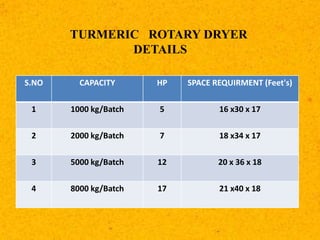

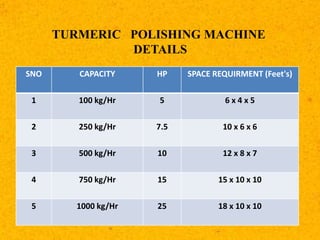

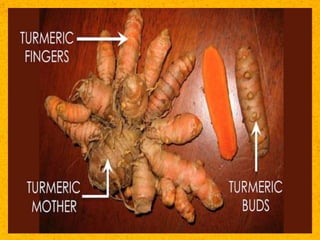

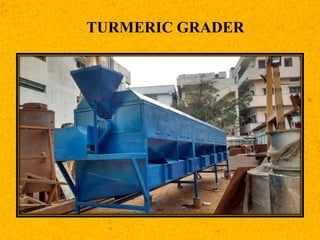

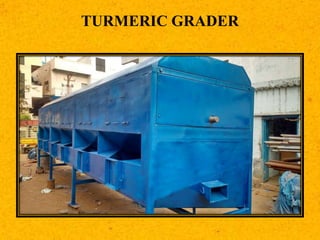

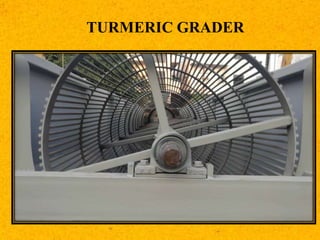

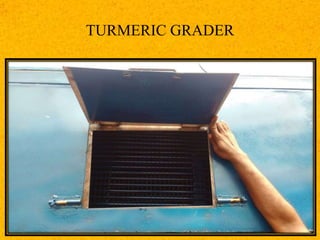

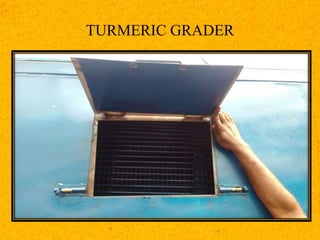

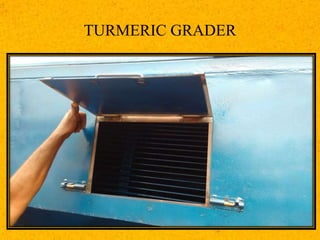

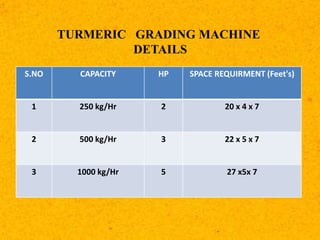

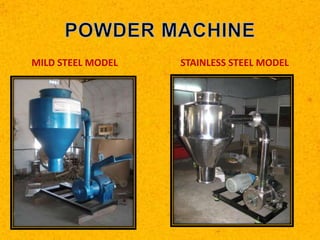

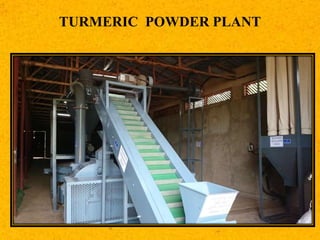

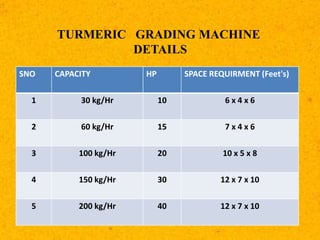

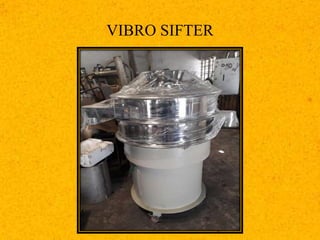

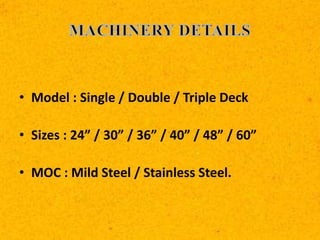

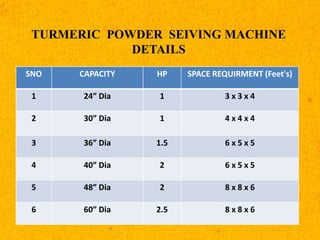

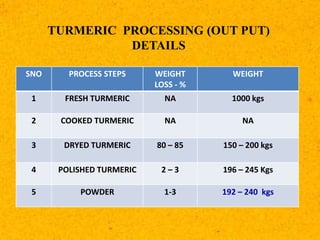

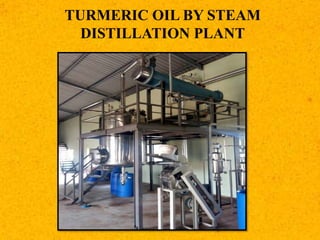

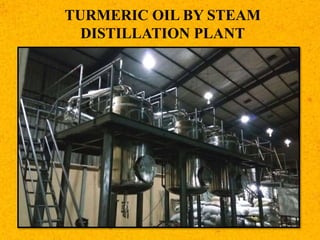

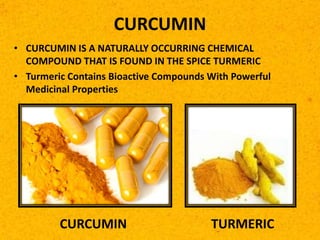

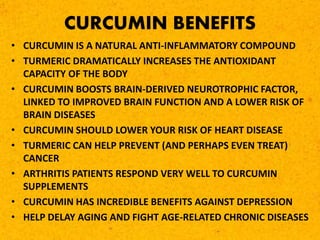

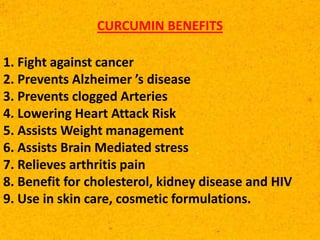

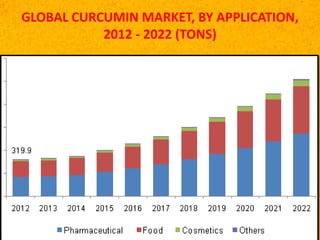

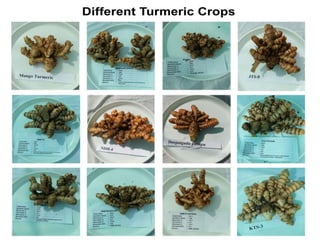

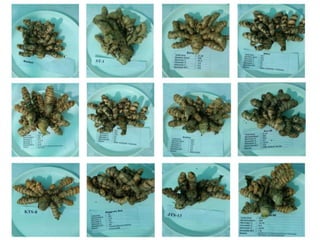

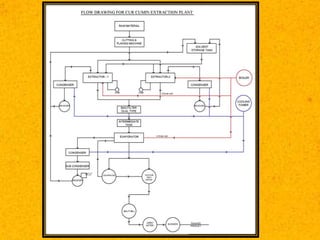

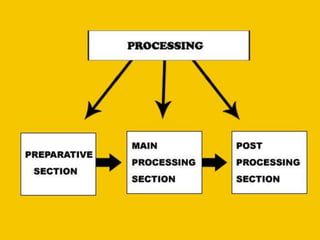

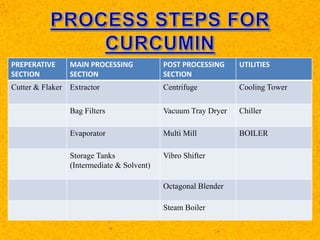

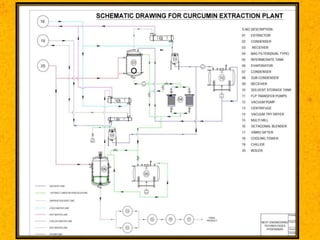

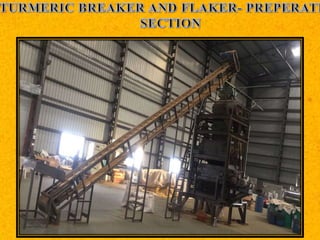

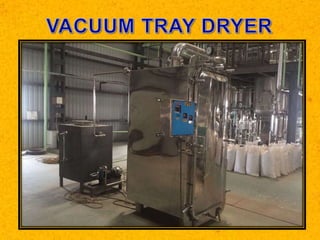

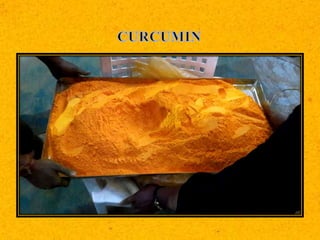

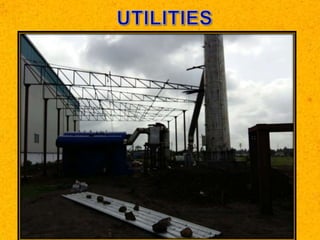

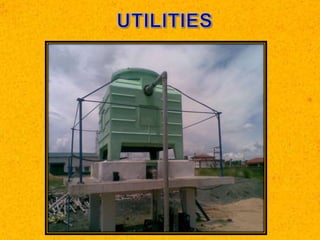

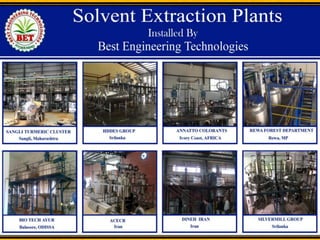

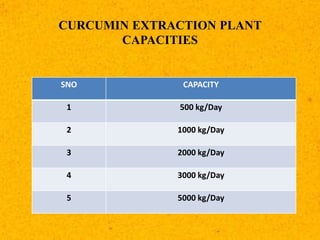

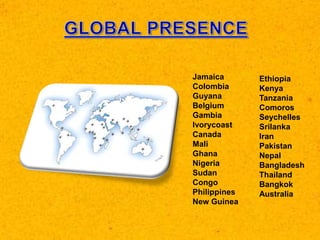

This document provides information about turmeric processing from various stages like washing, cooking, drying, polishing, grading, grinding and value addition processes like turmeric oil extraction and curcumin extraction. It includes details of machinery used in each process with specifications and capacities. Benefits of turmeric, curcumin and value added products are highlighted. A flow chart depicting the overall turmeric processing is presented along with output details at each stage. Global curcumin market outlook is also summarized. Contact details of the engineering company specializing in turmeric processing equipment are provided at the end.