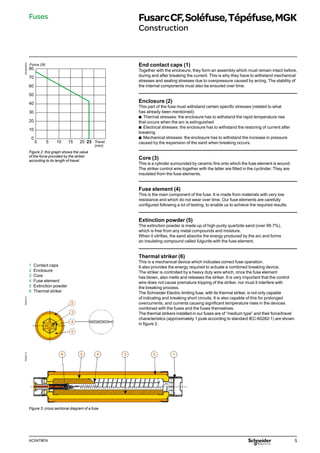

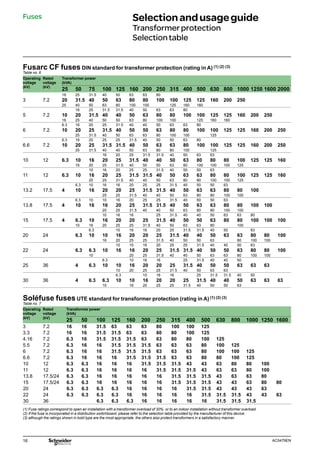

This document provides information on medium voltage fuses from 3.6 kV to 36 kV produced by Hoang Phuong Electric Equipment Company. It includes an introduction to their Fusarc CF, Soléfuse, Tépéfuse, and MGK fuse lines and descriptions of their applications, characteristics, standards, quality control processes, and key definitions. Tables and diagrams are provided showing fuse ratings and operating ranges. The construction of the fuses is also detailed, including components like the end caps, enclosure, core, fuse element, and thermal striker.