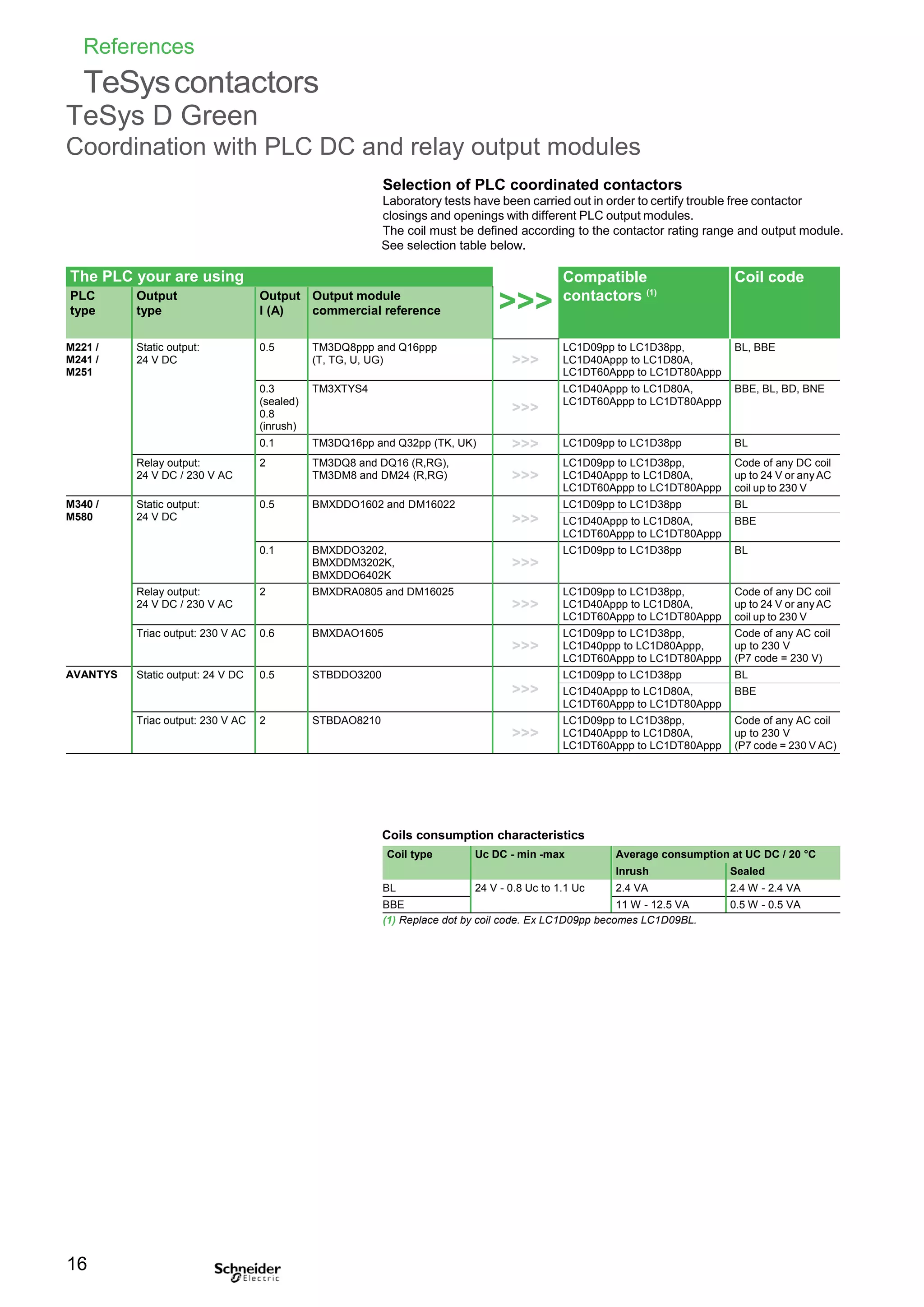

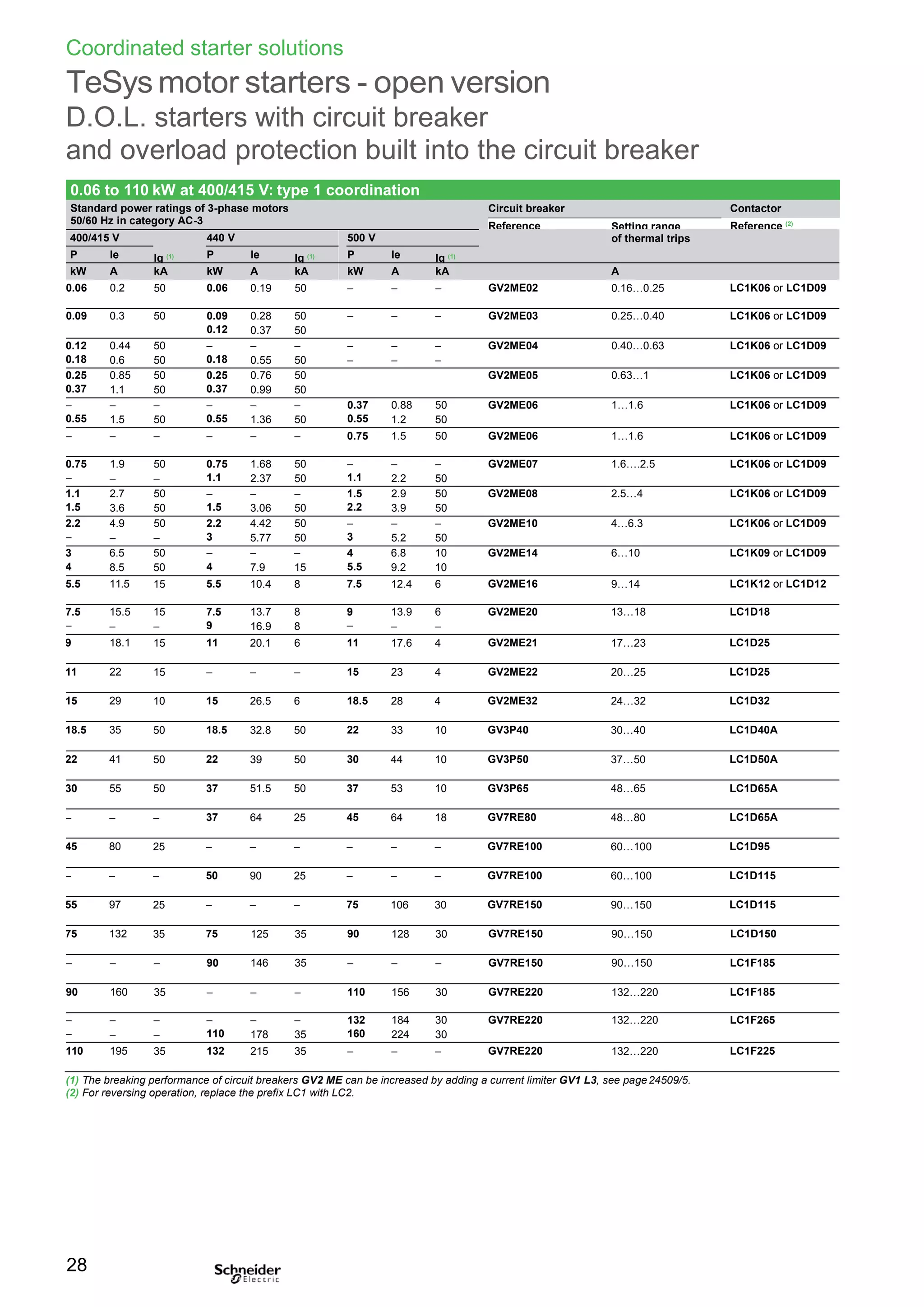

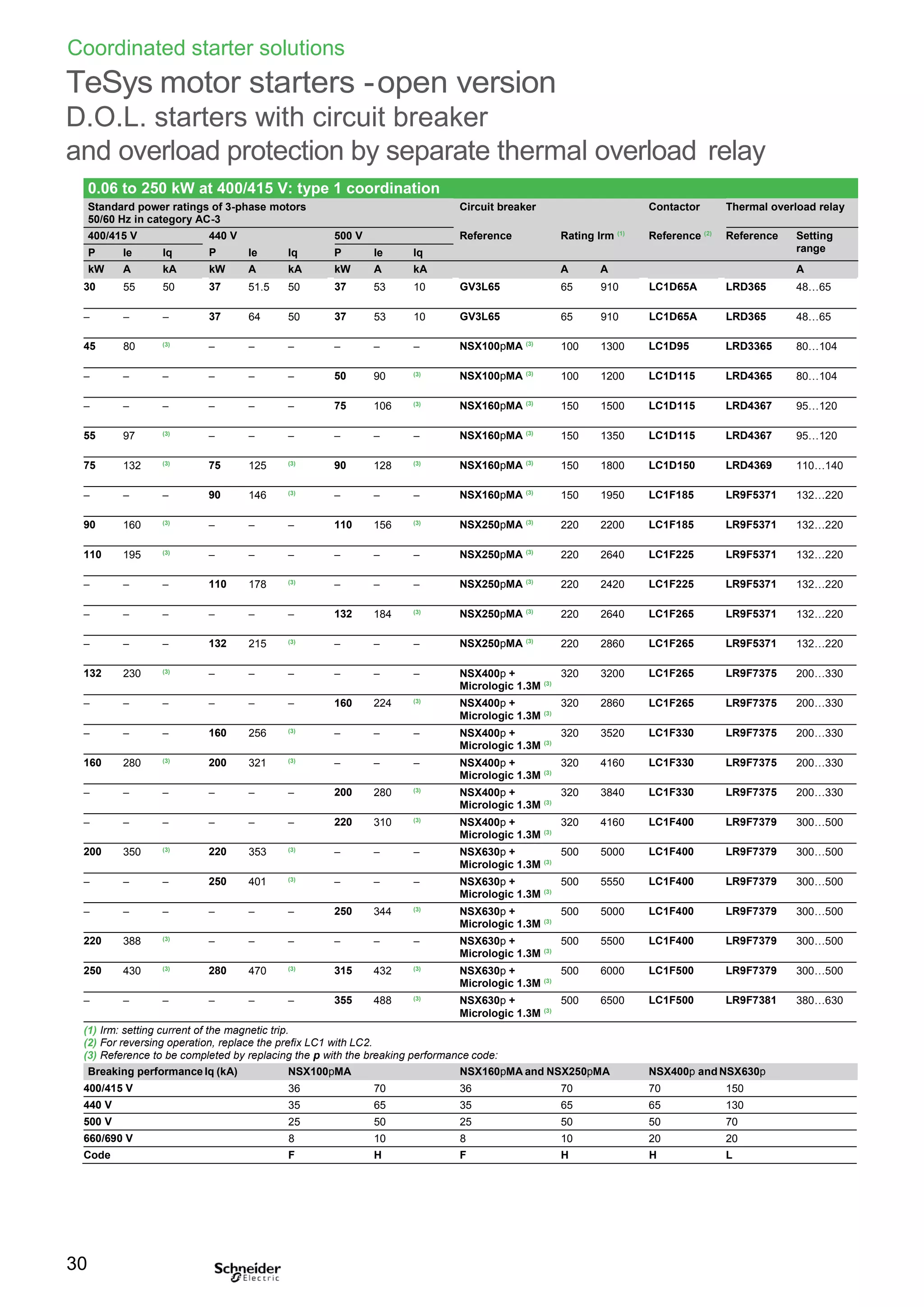

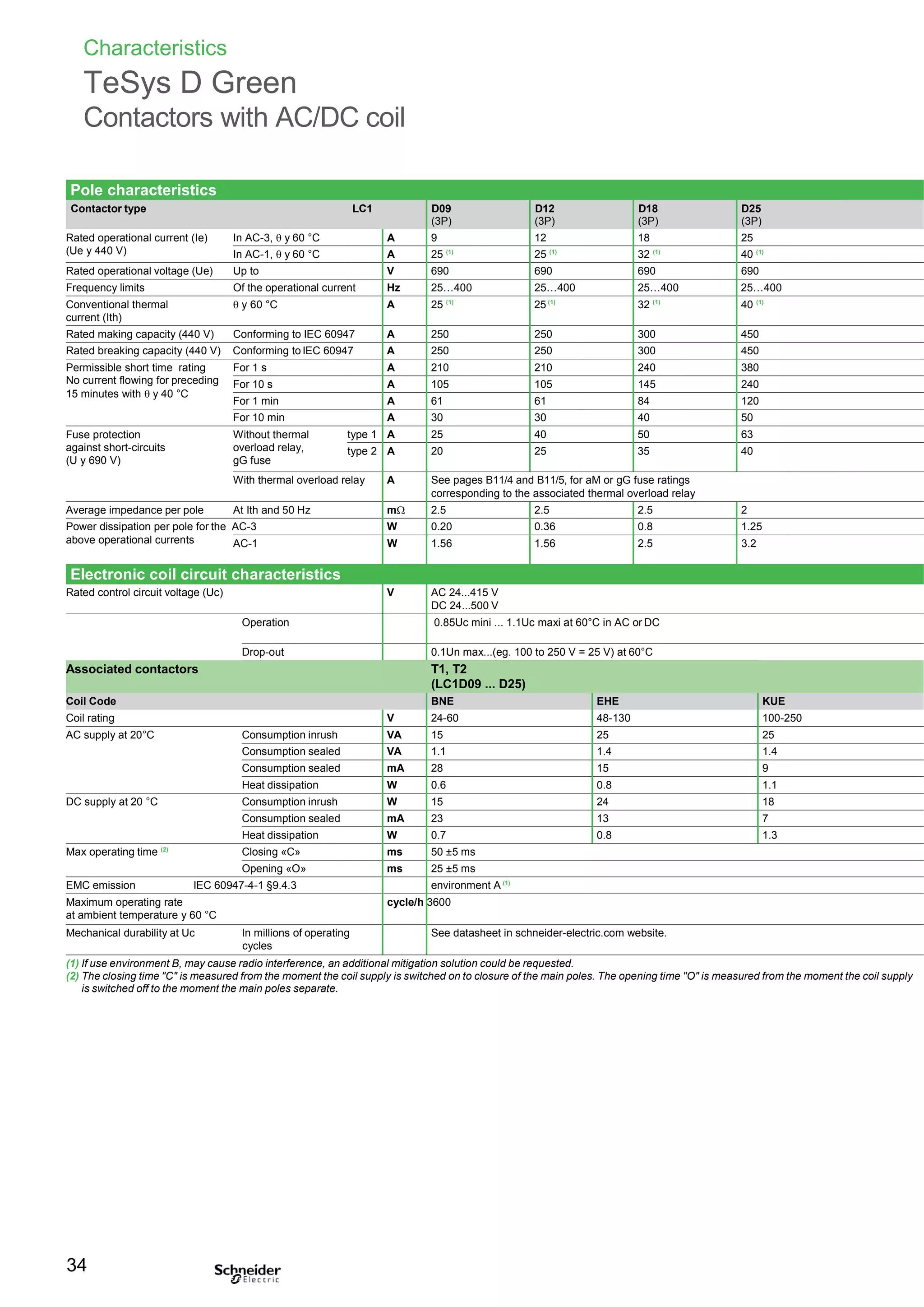

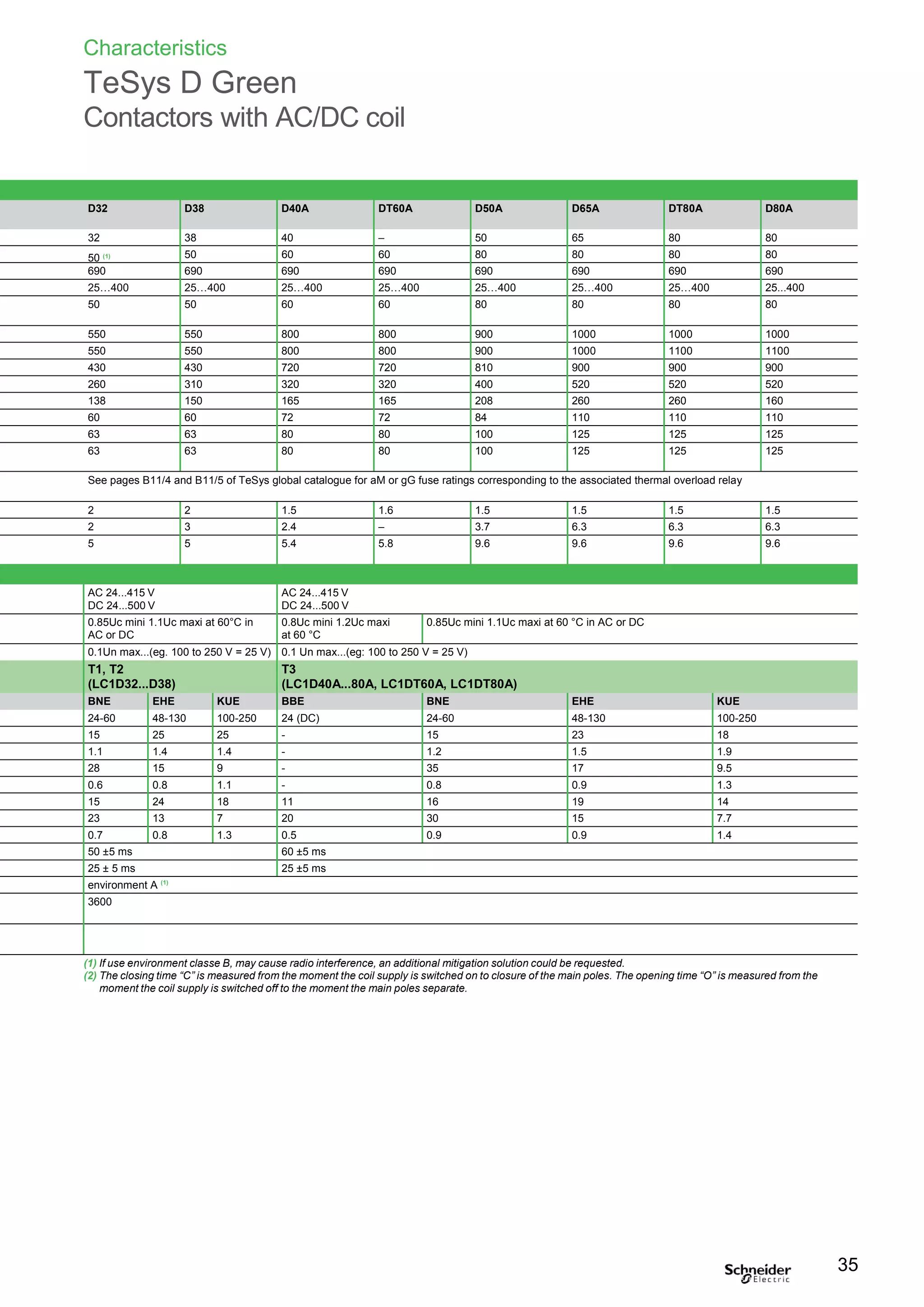

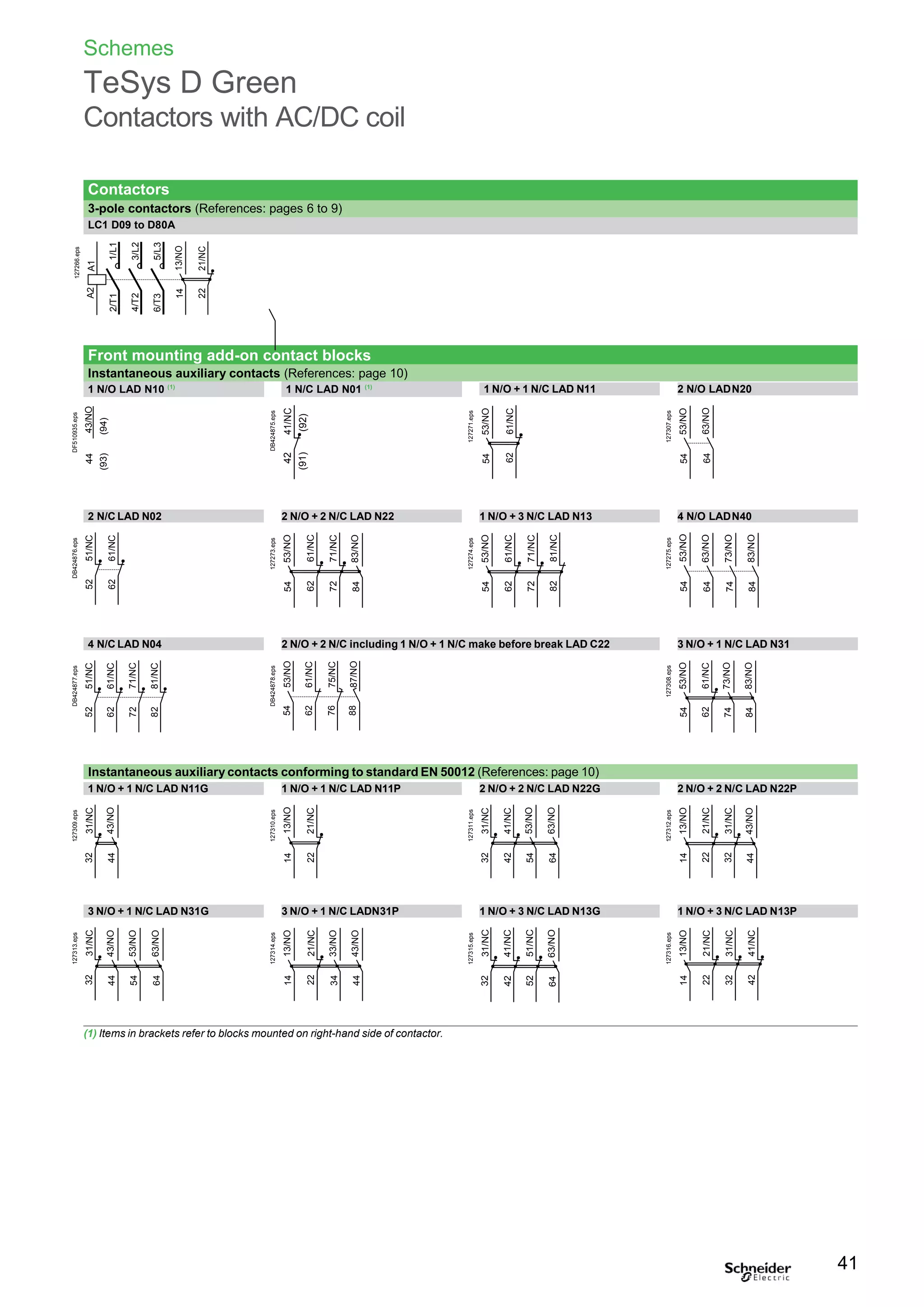

This document provides contact and contactor references for TeSys D Green contactors. It lists contactor models for 3-phase motors from 9A to 150A, along with auxiliary contact blocks, accessories, and mounting systems. Technical specifications are provided for each contactor model, including voltage ratings, current ratings, weight, and fixing options.