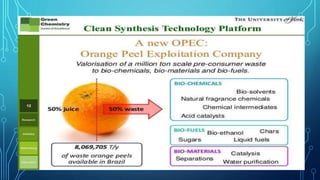

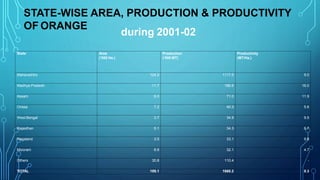

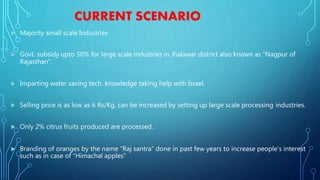

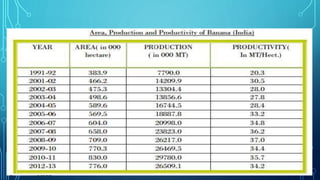

The document discusses the processing of fruits and vegetables, highlighting methods like canning, drying, and freezing that enhance shelf life. It outlines waste management practices to mitigate environmental impacts, such as reducing wastewater and utilizing by-products, alongside a focus on specific crops and their processing in various Indian states. Furthermore, it covers the current agricultural scenarios and government initiatives to support processing industries and improve productivity.