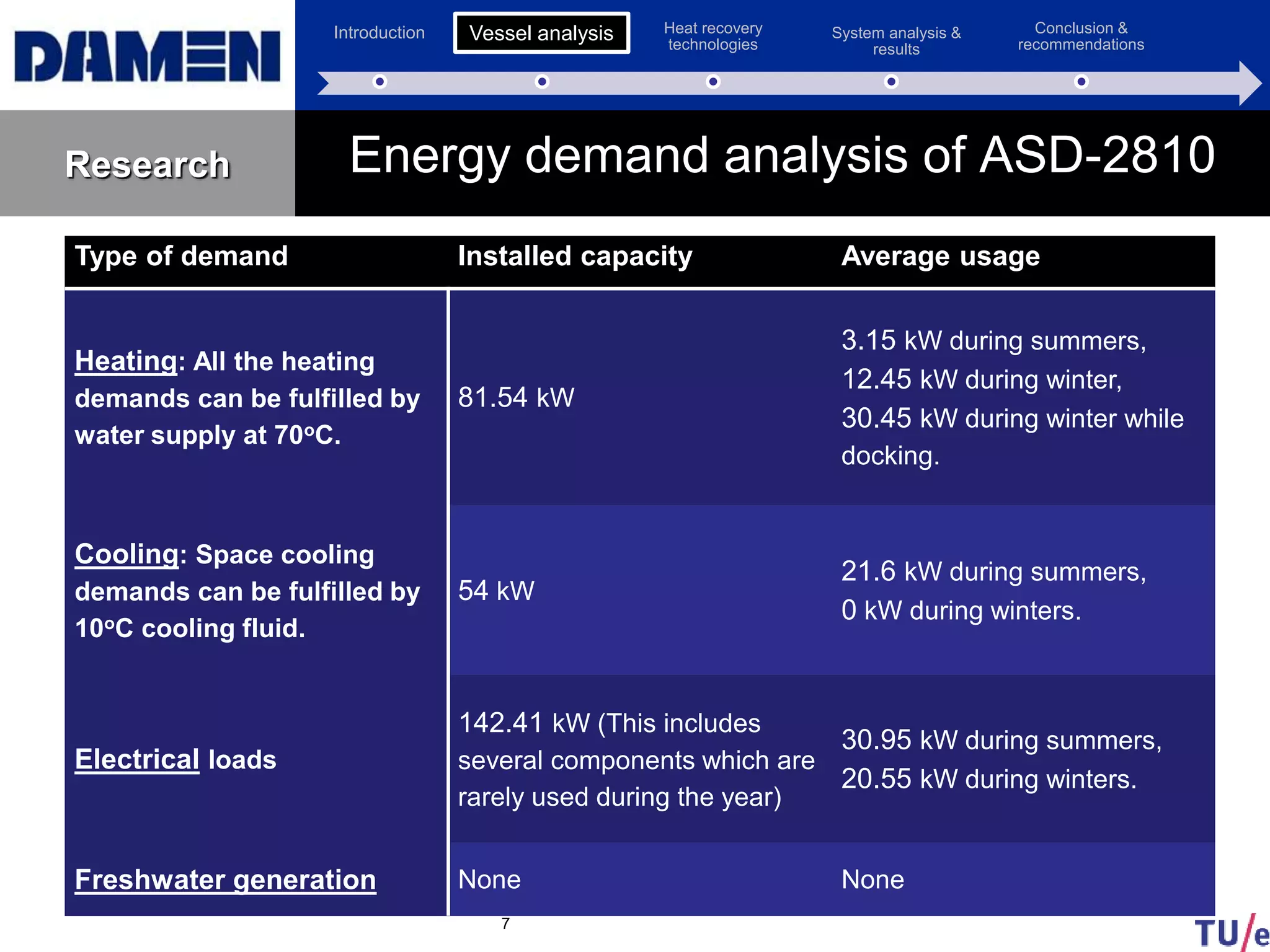

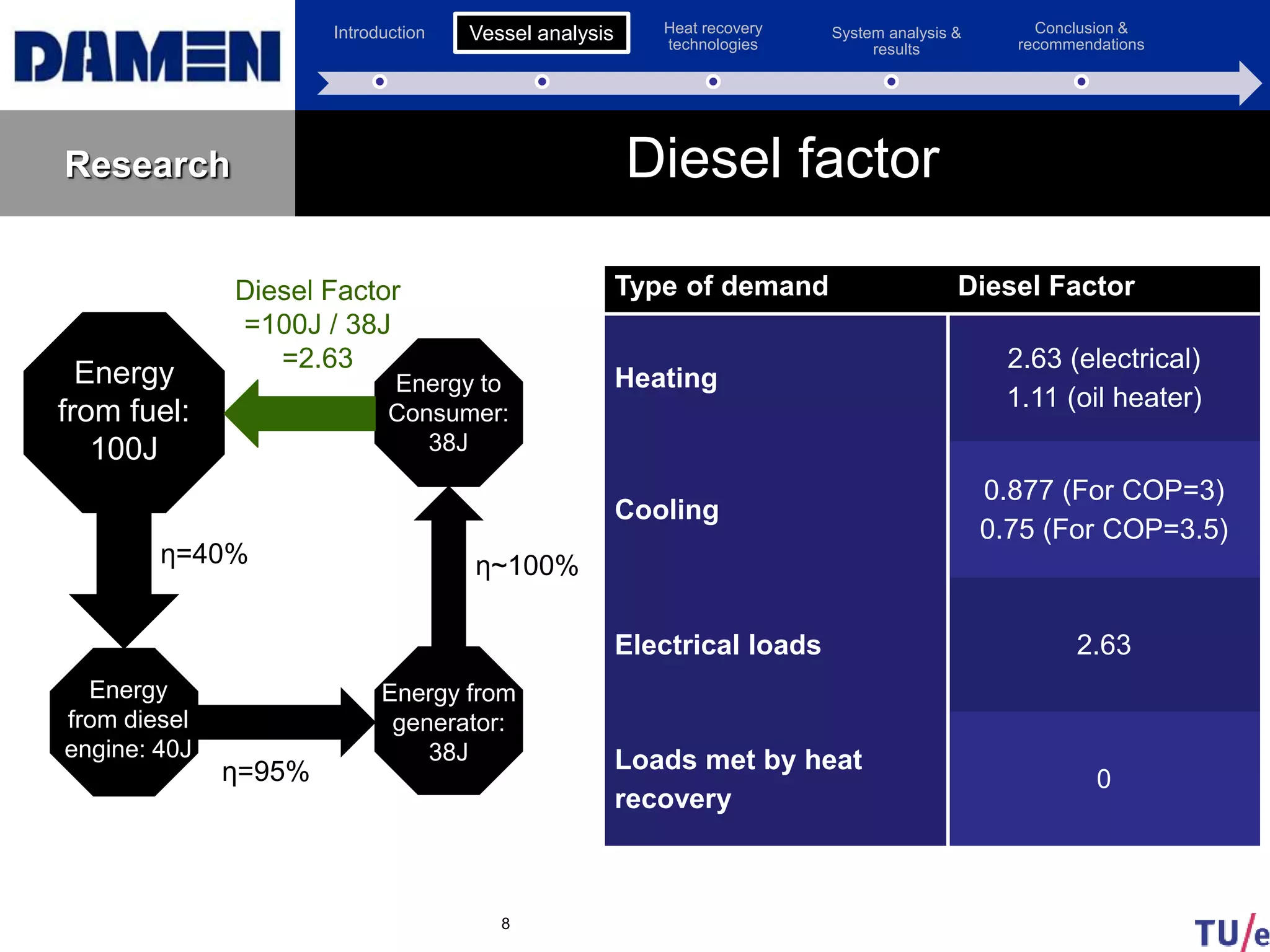

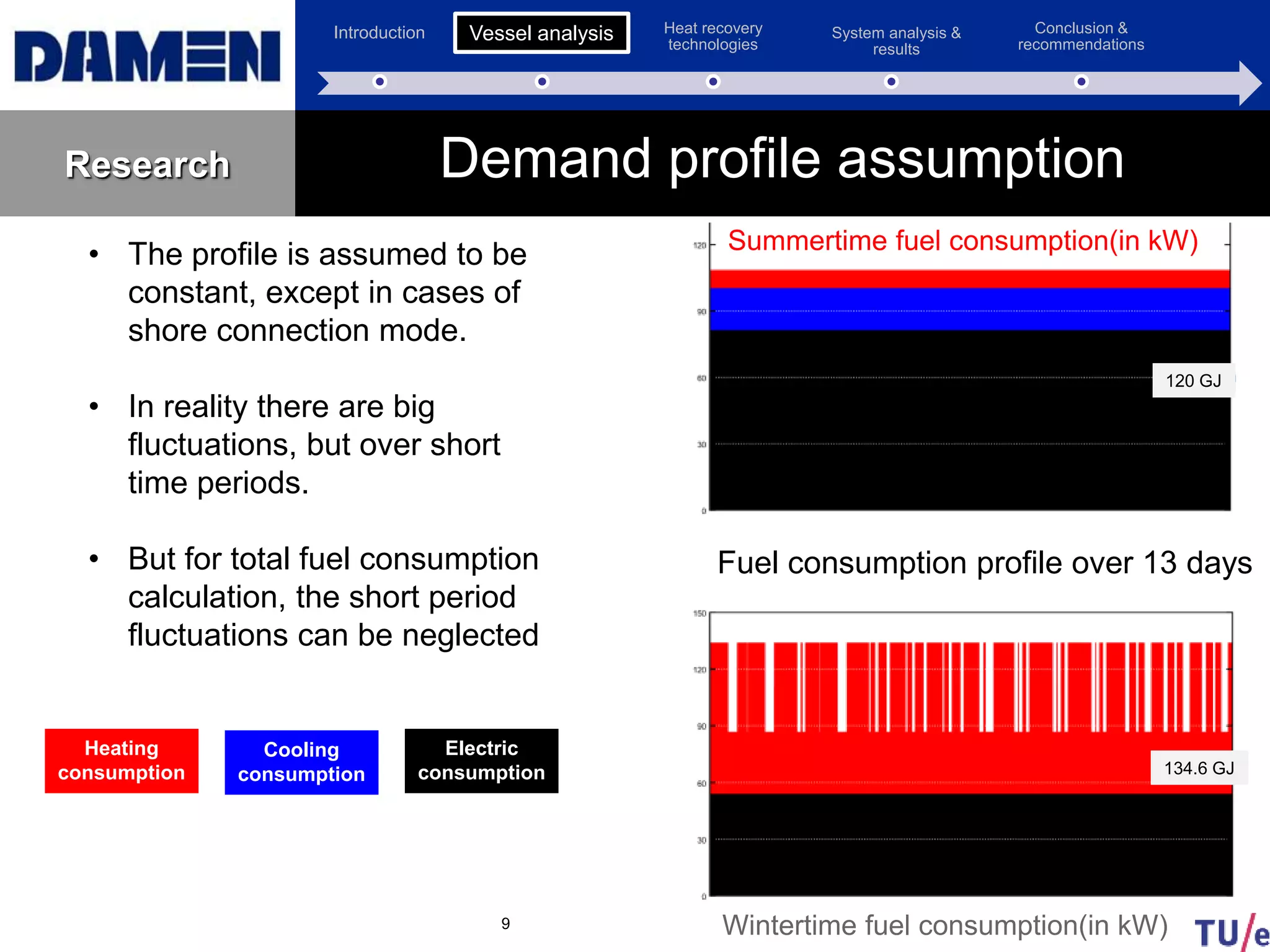

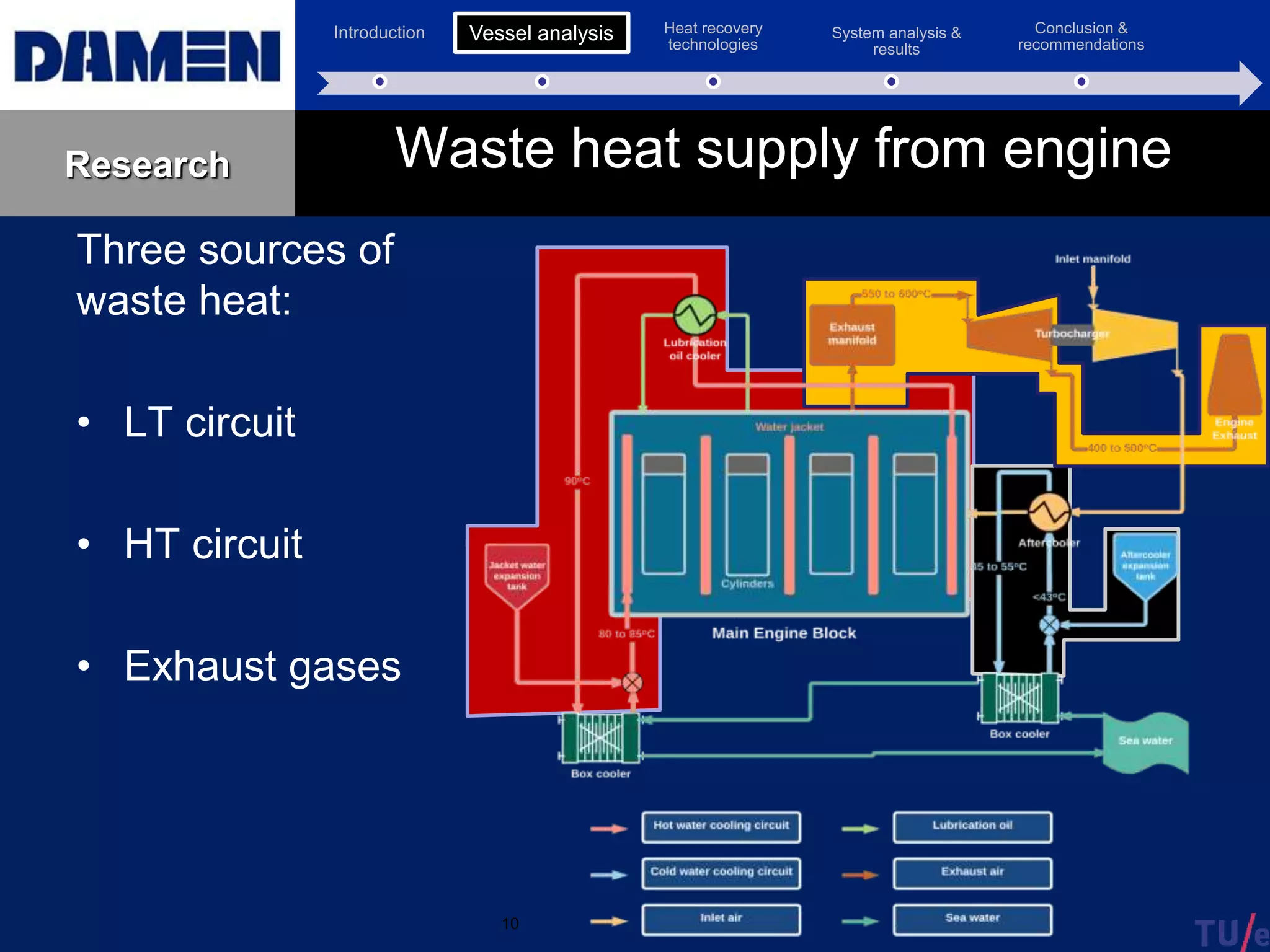

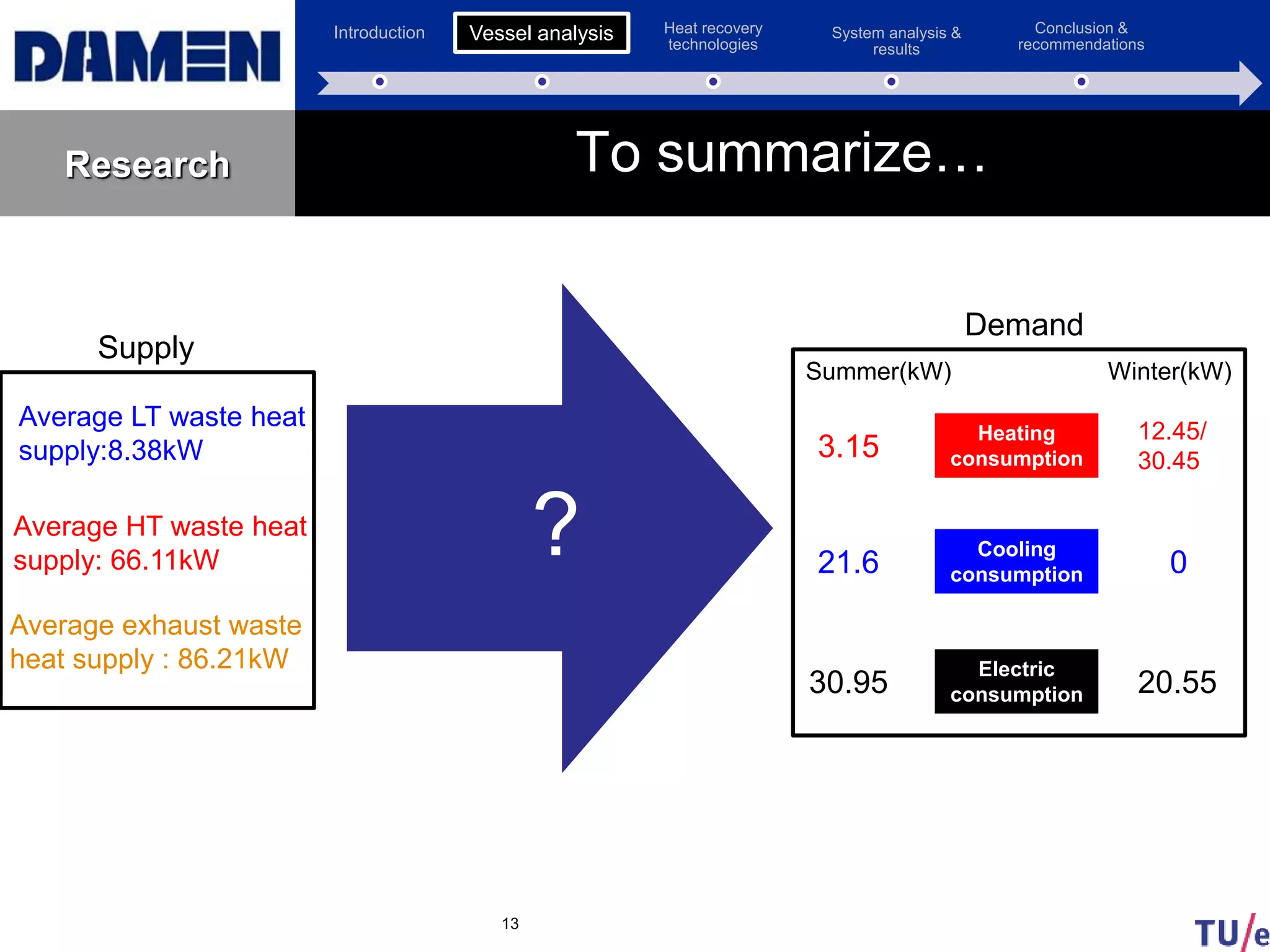

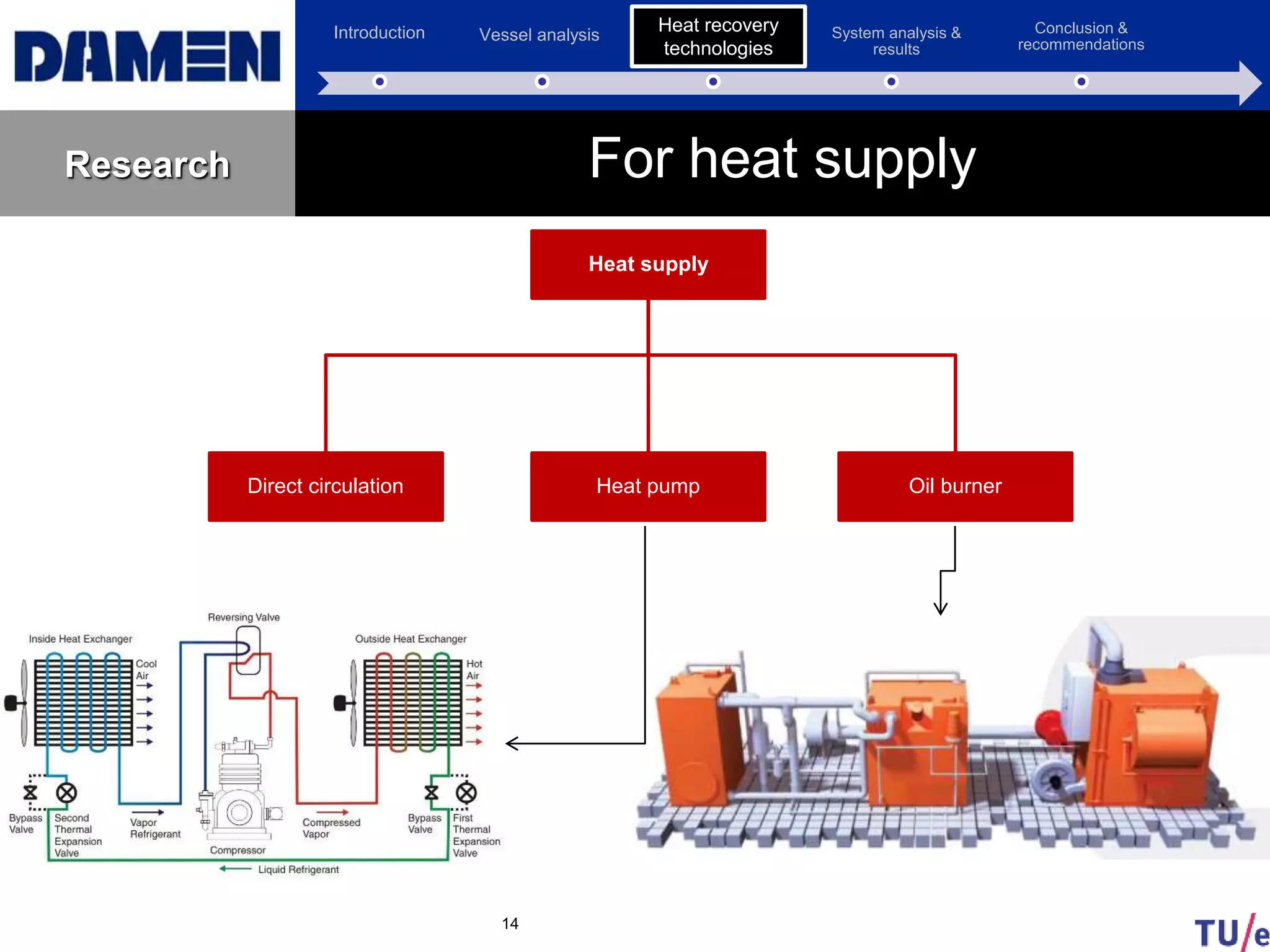

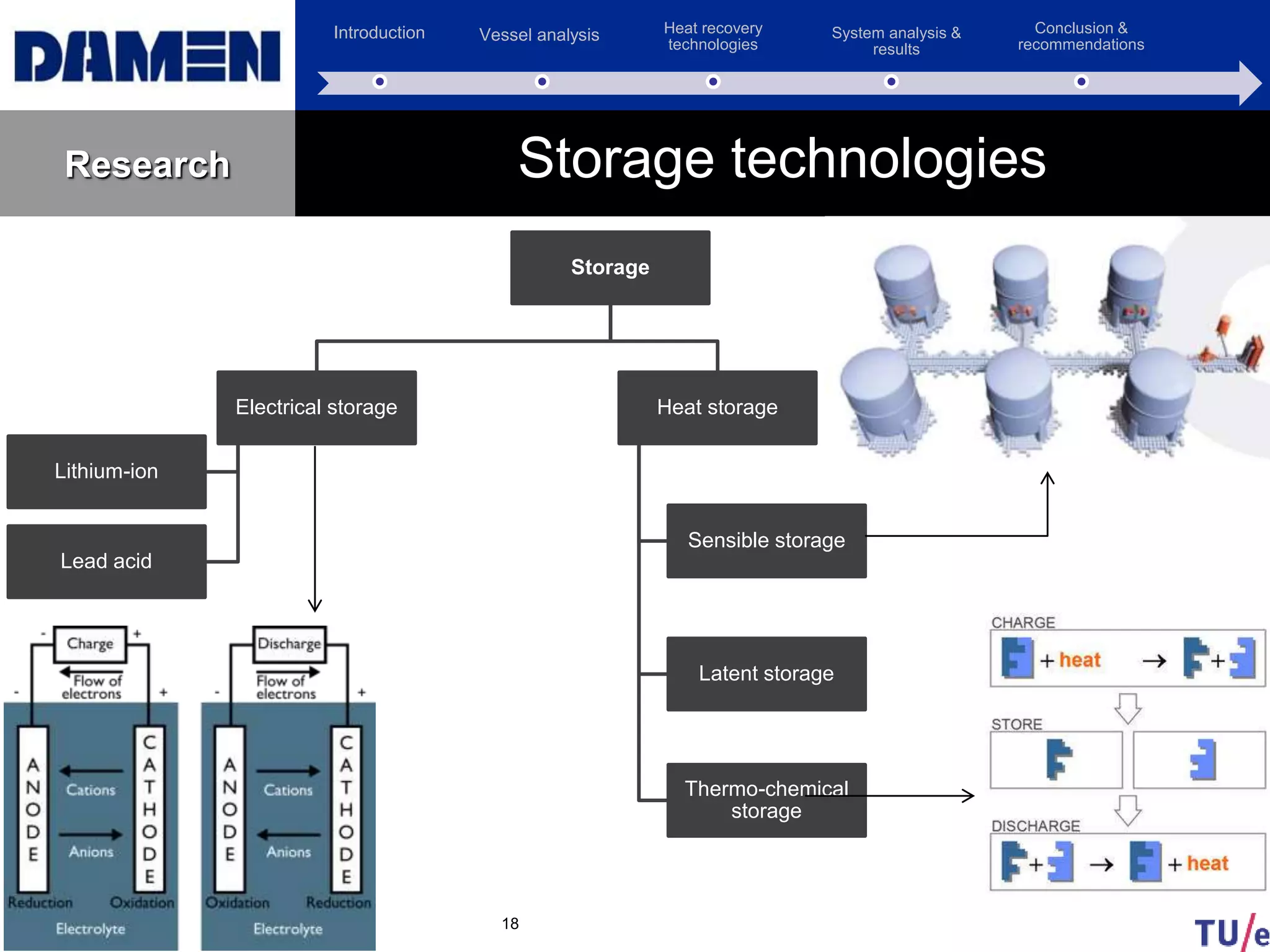

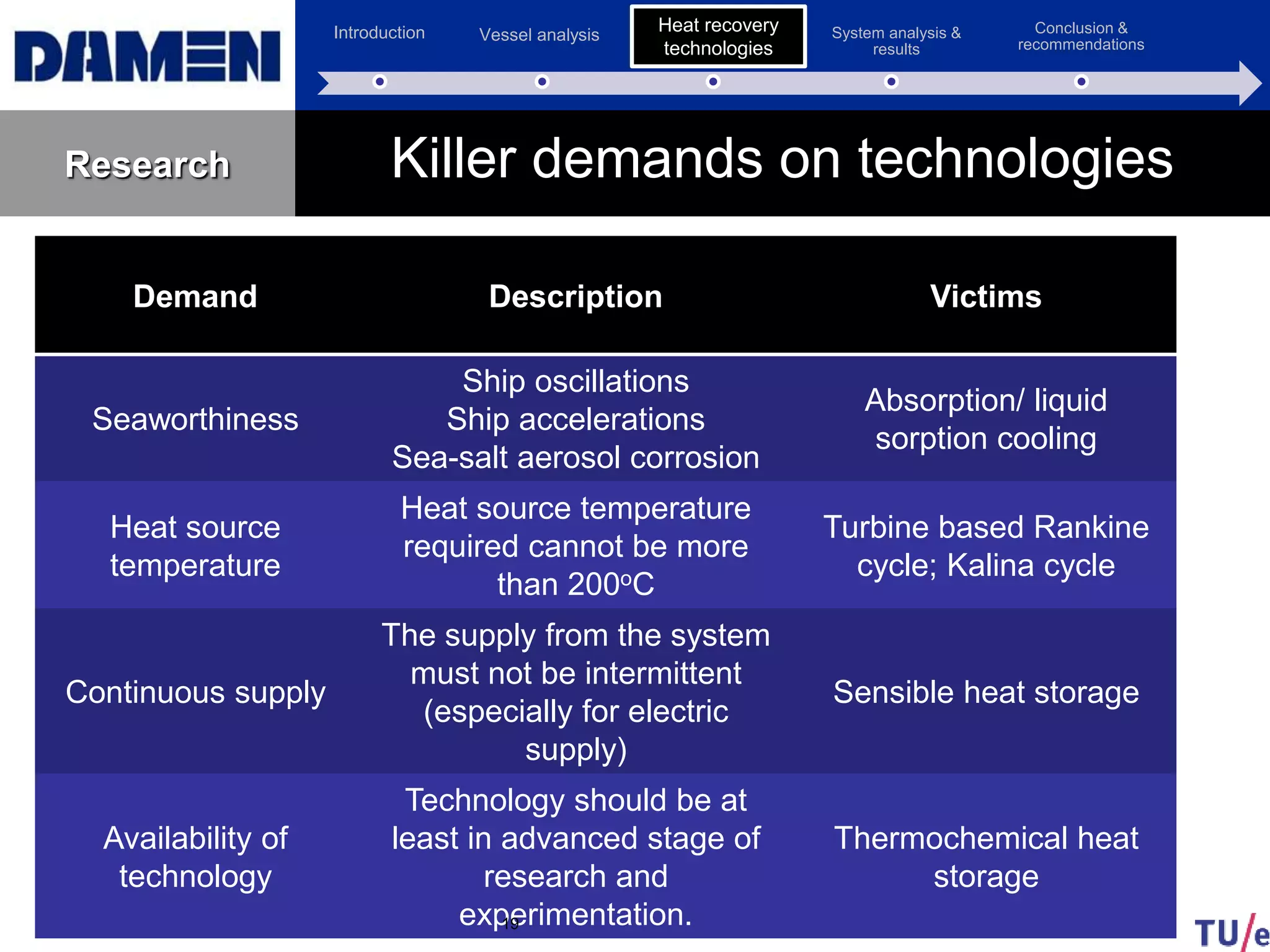

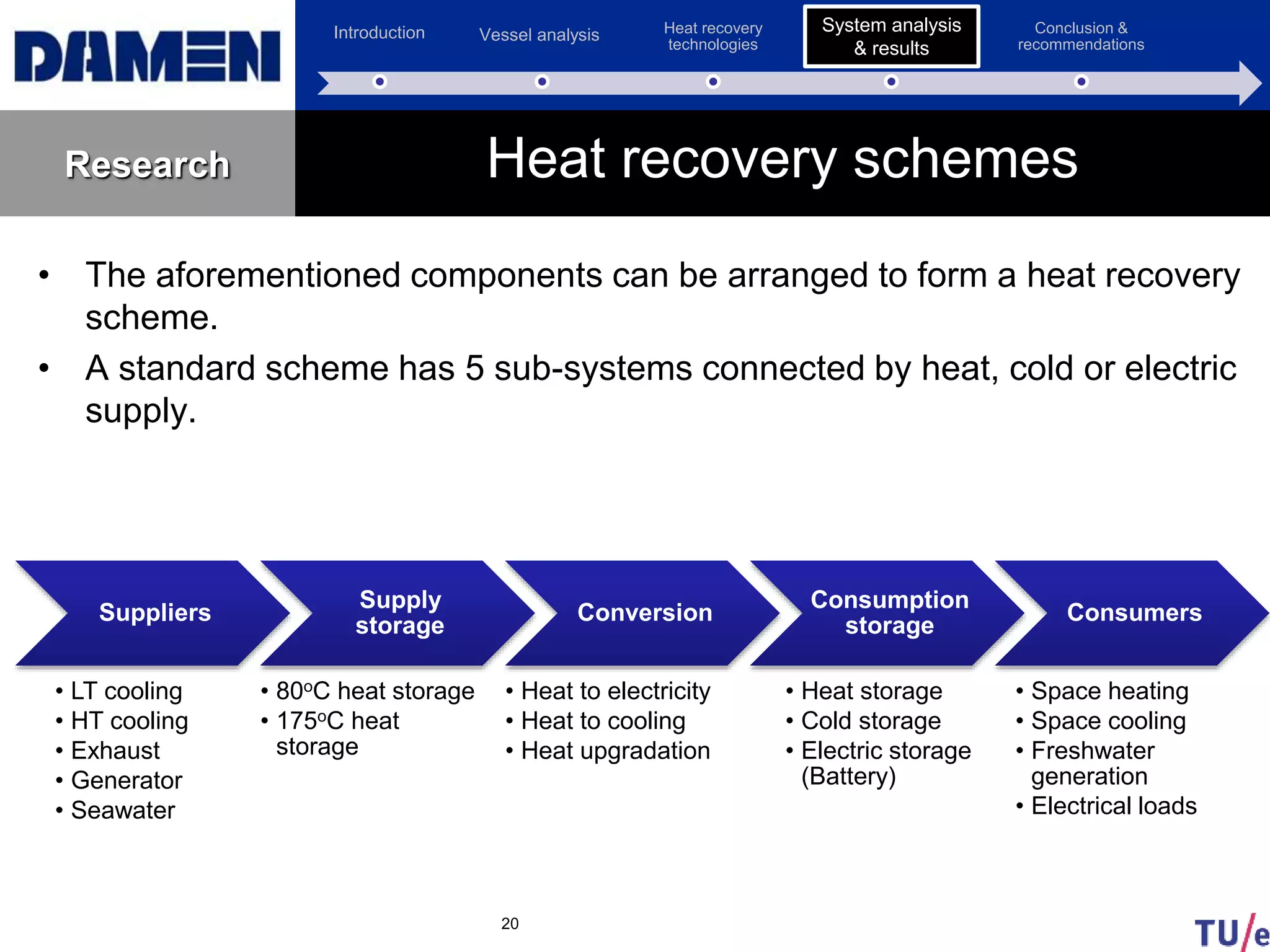

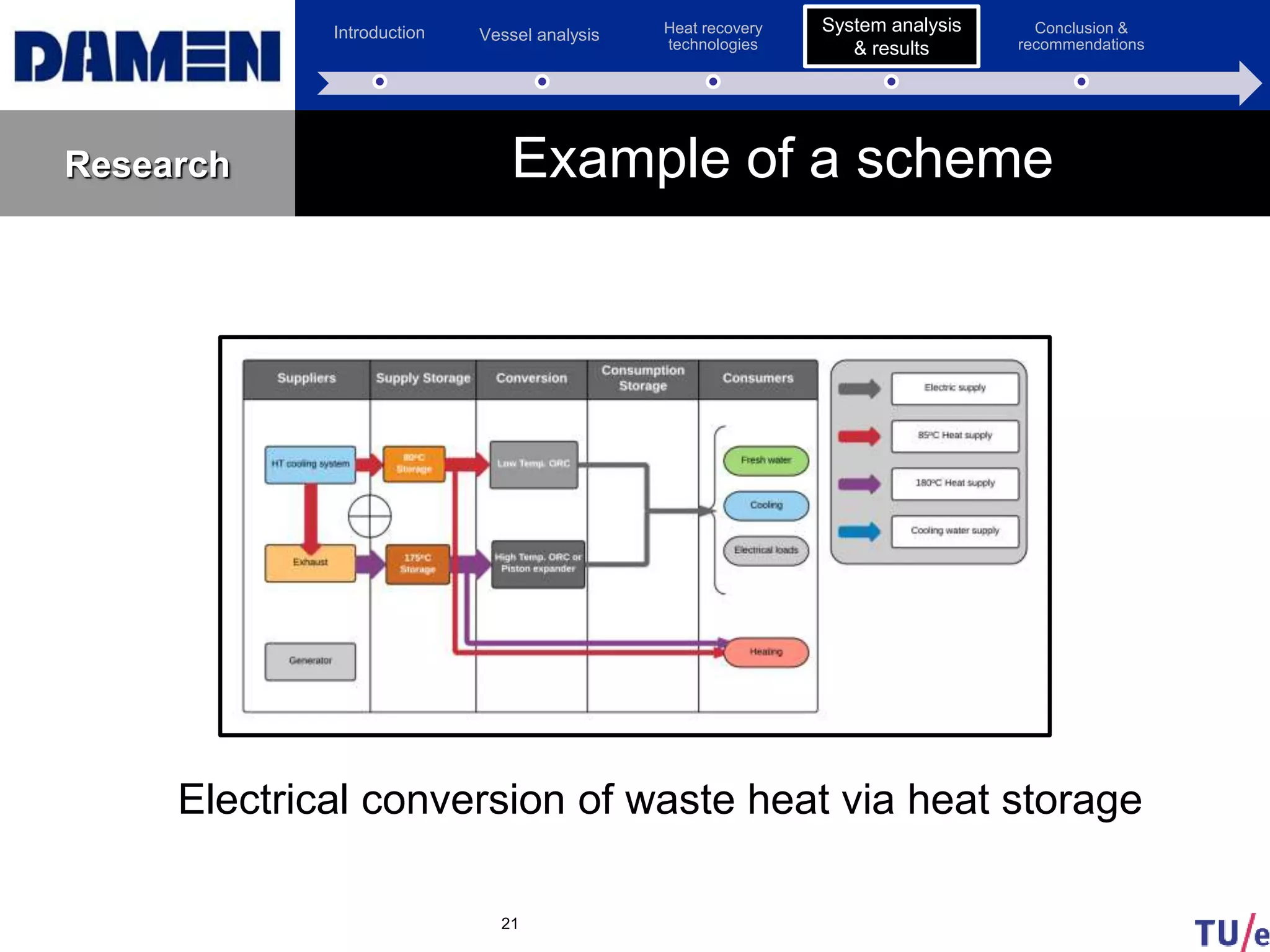

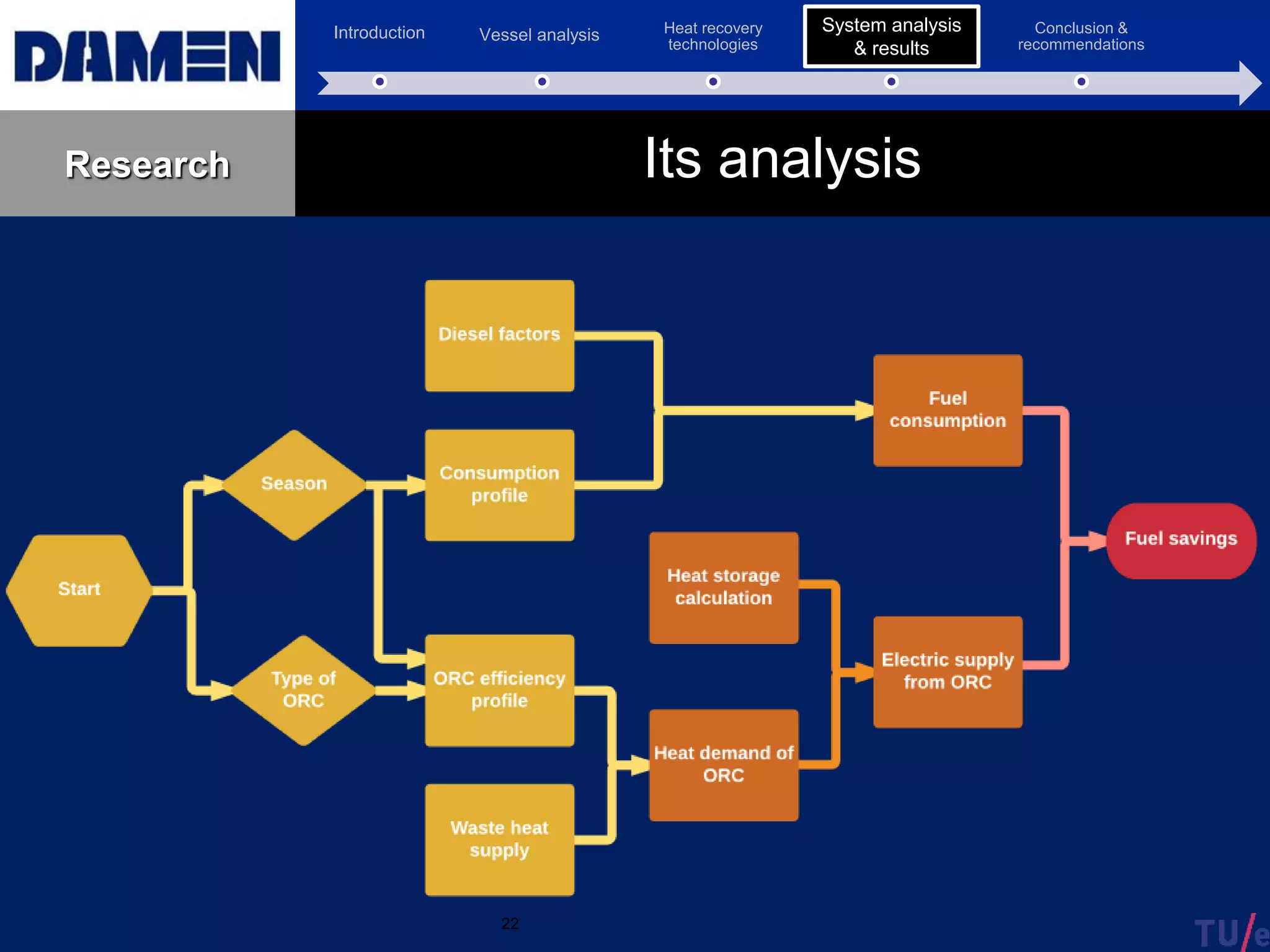

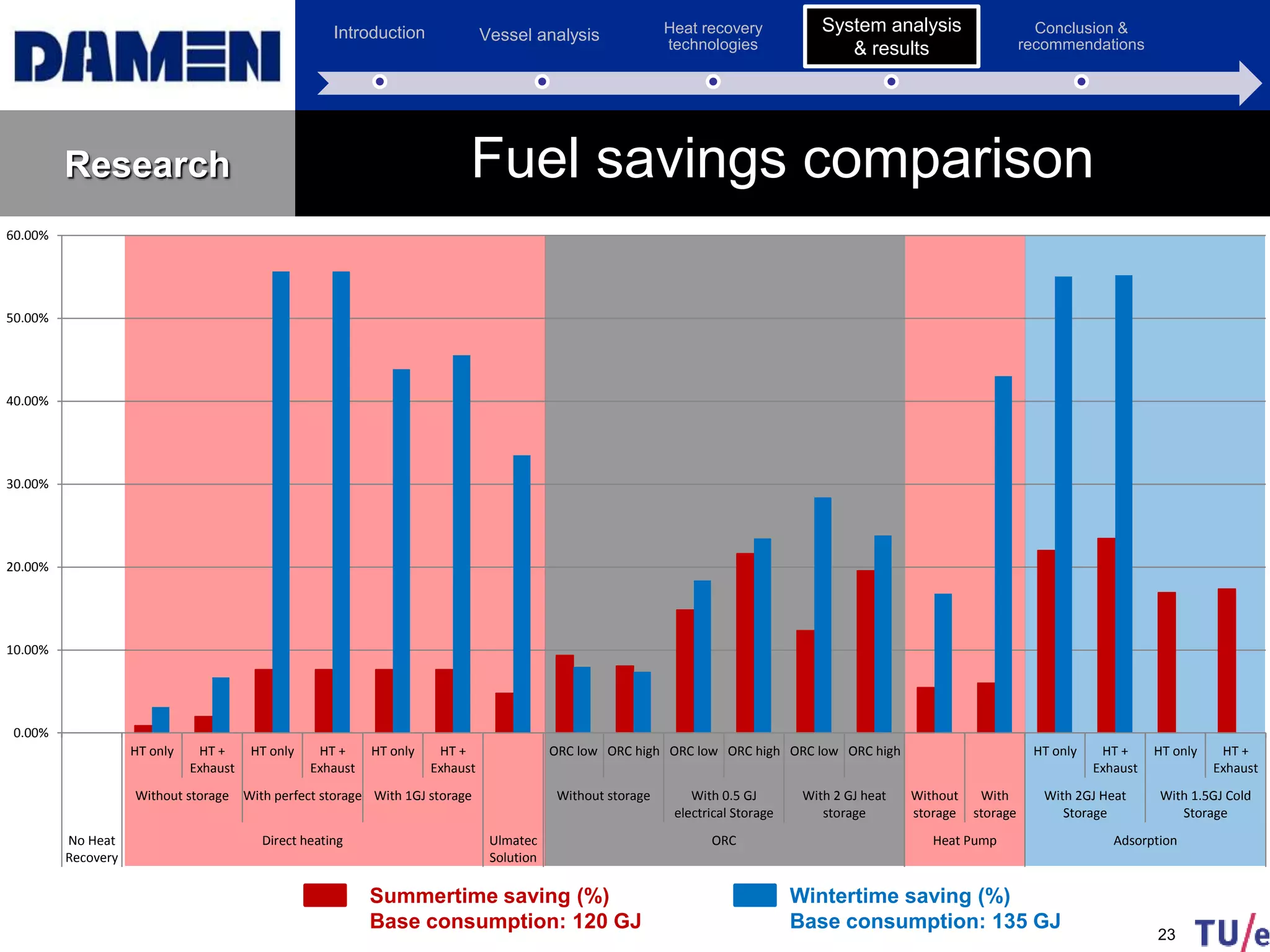

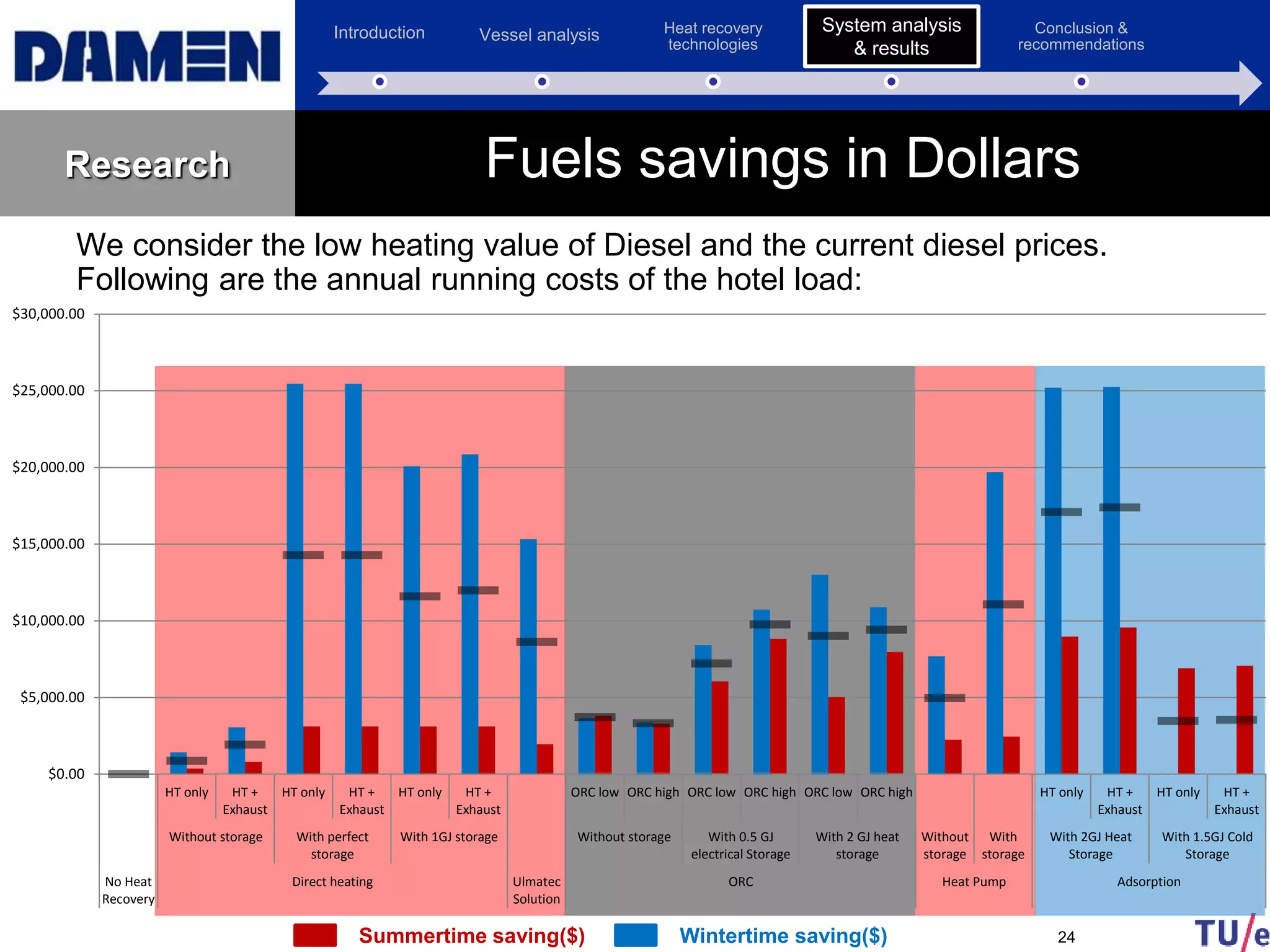

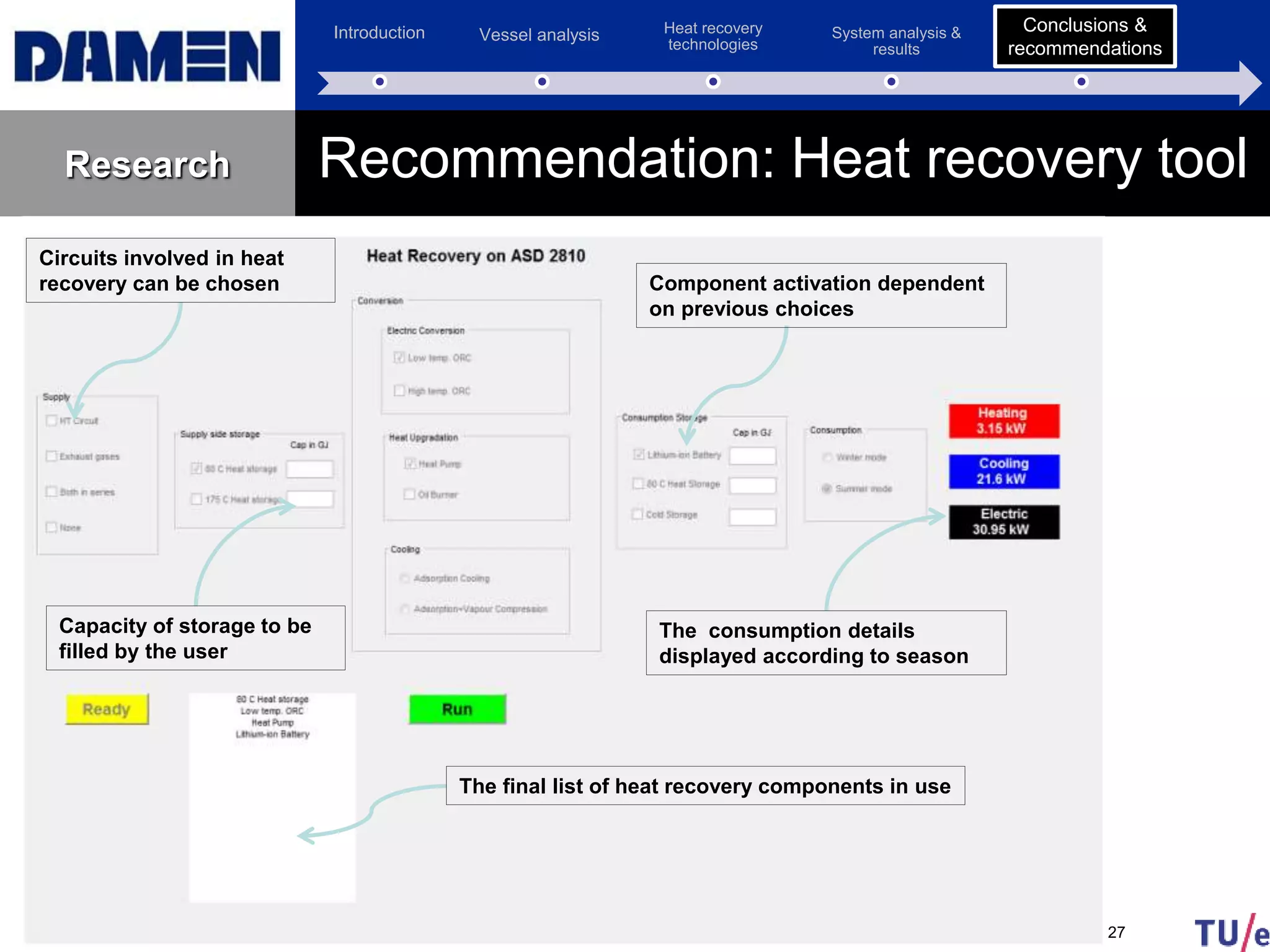

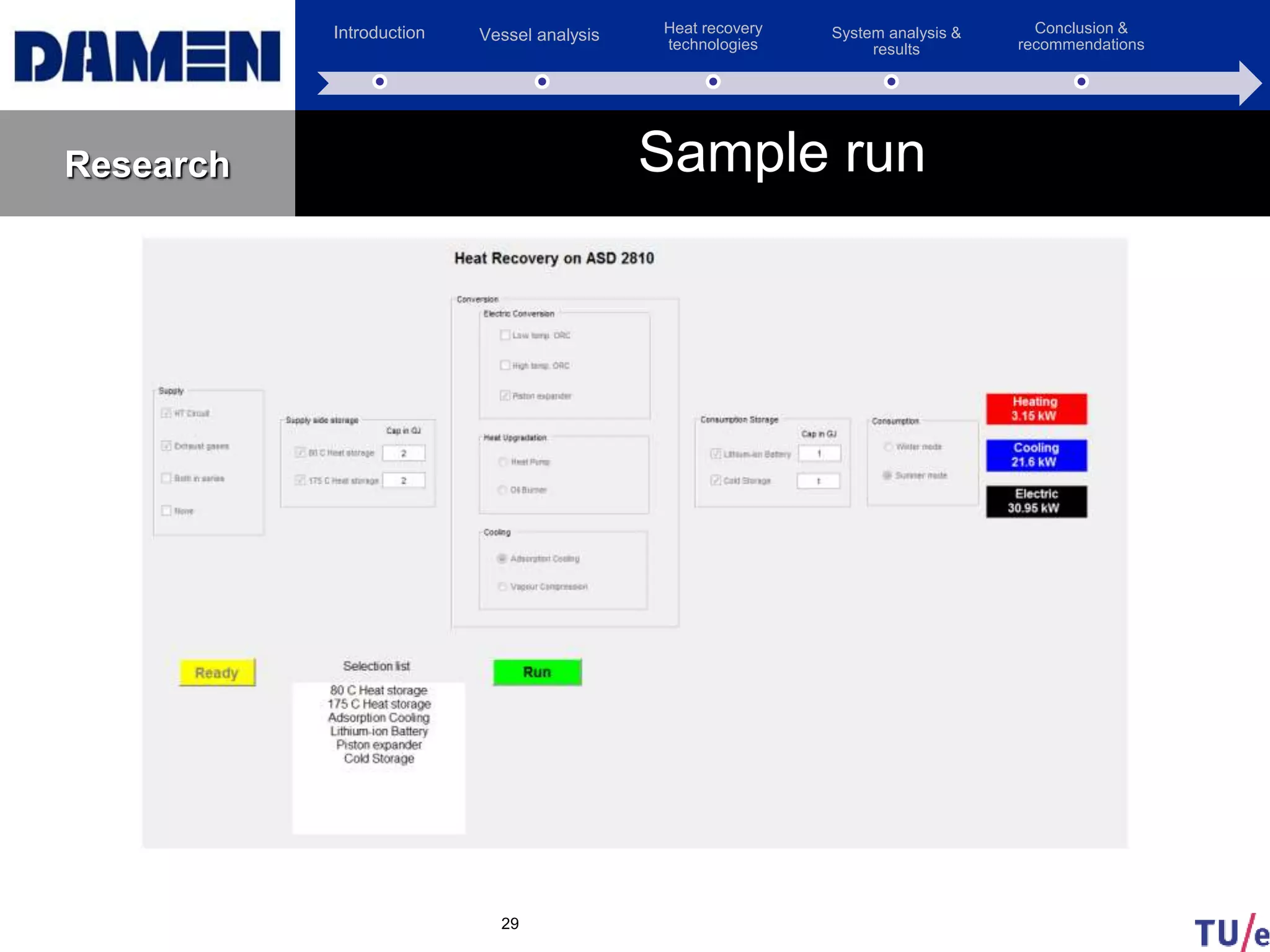

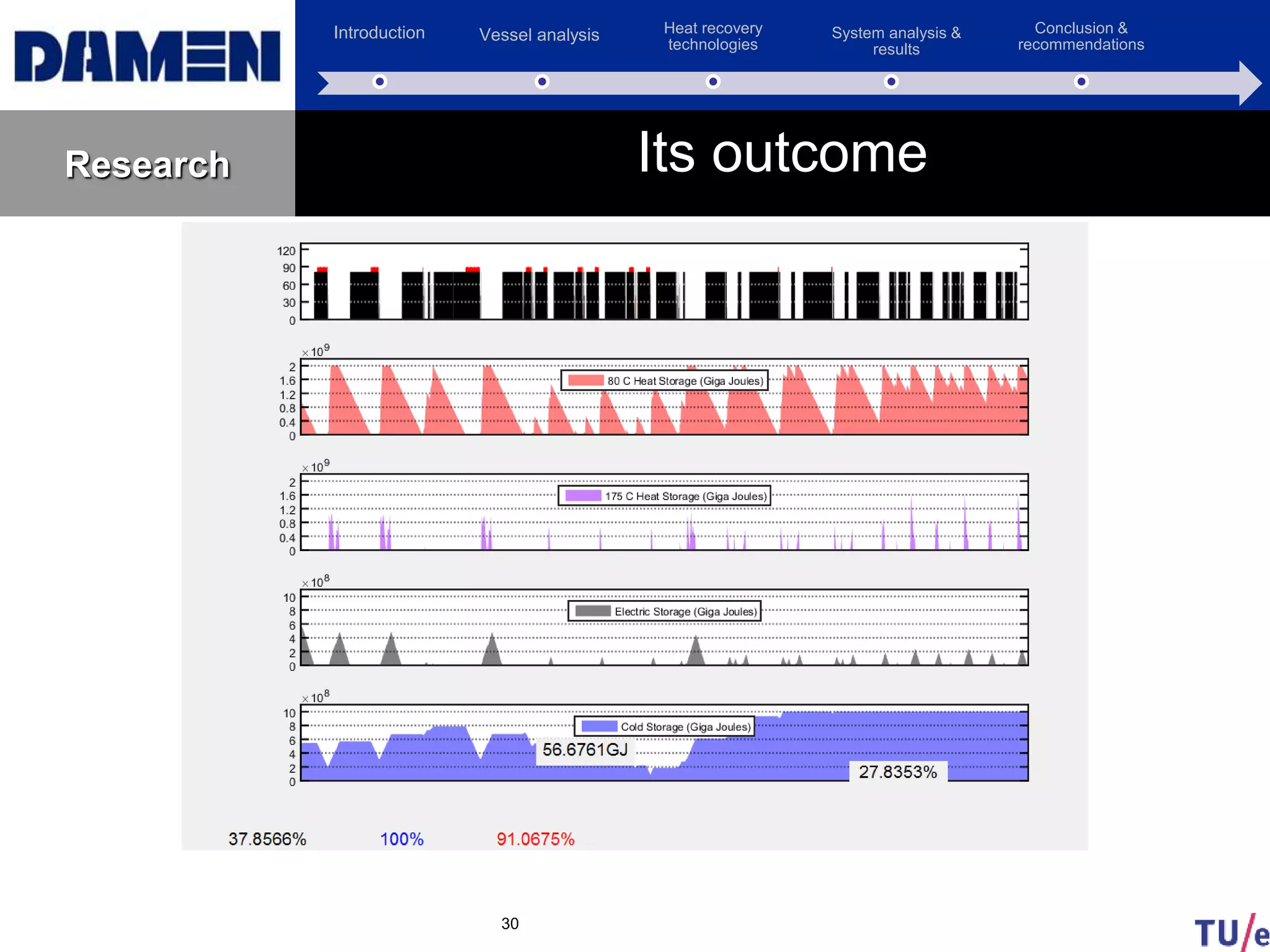

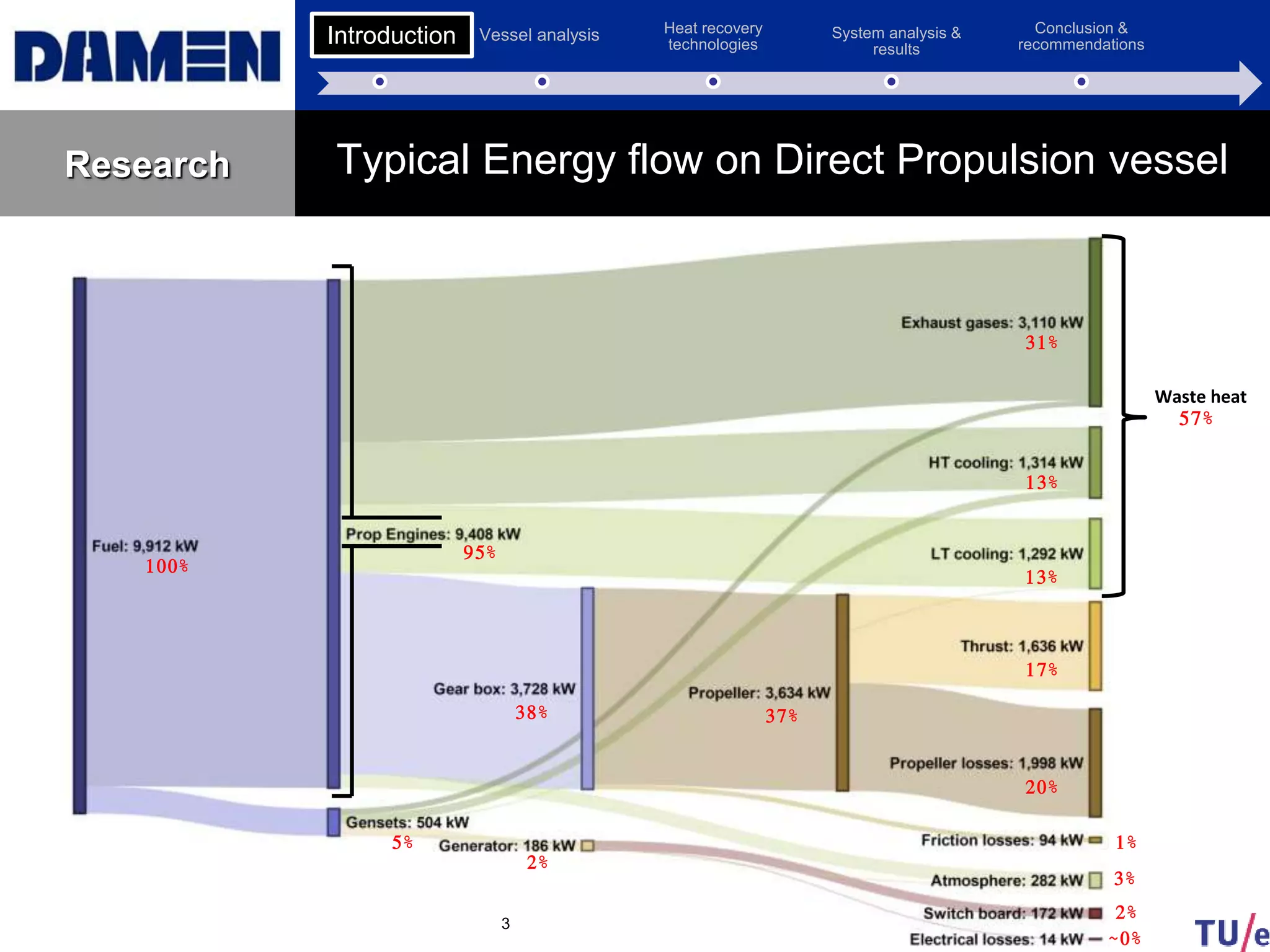

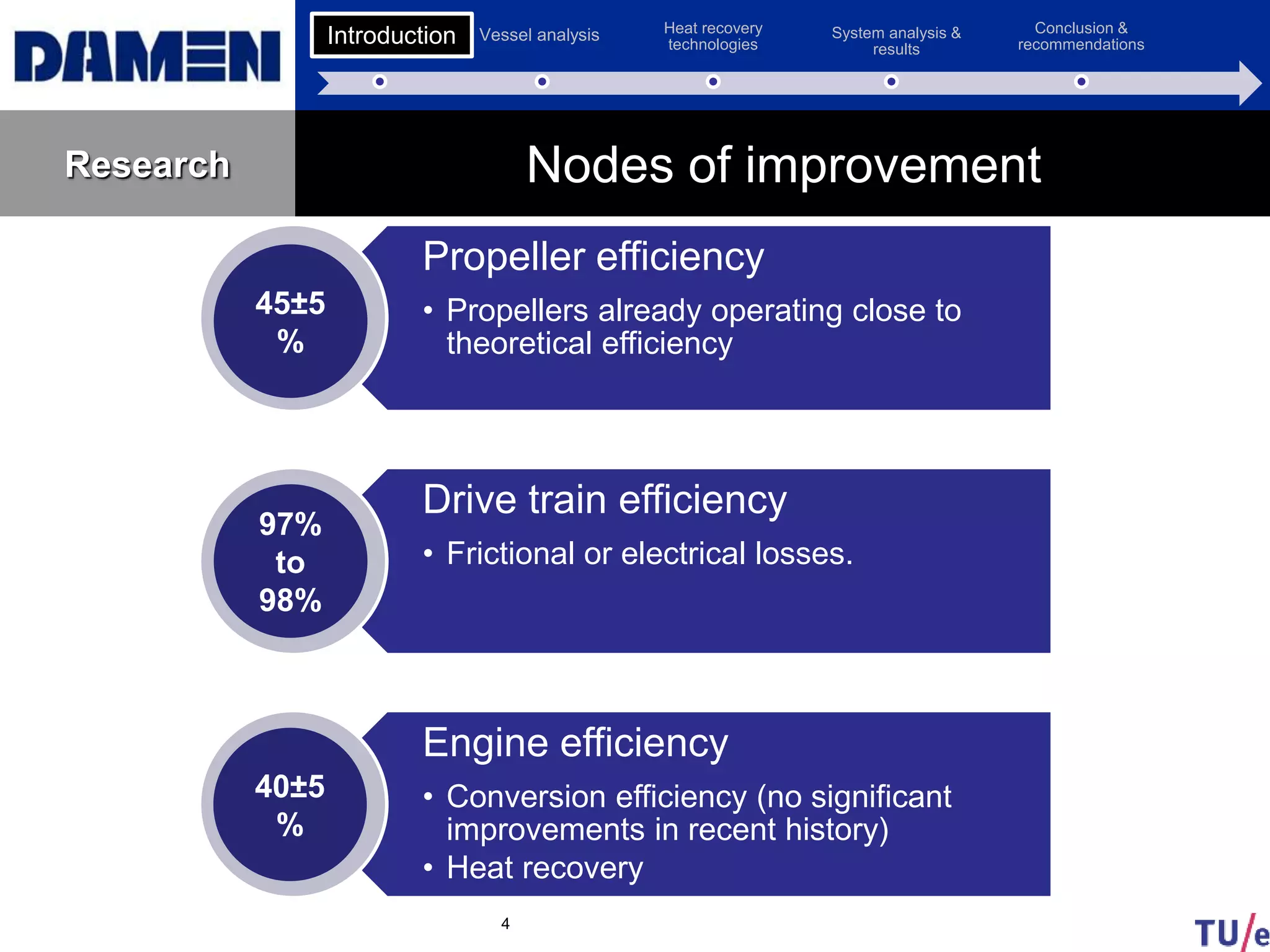

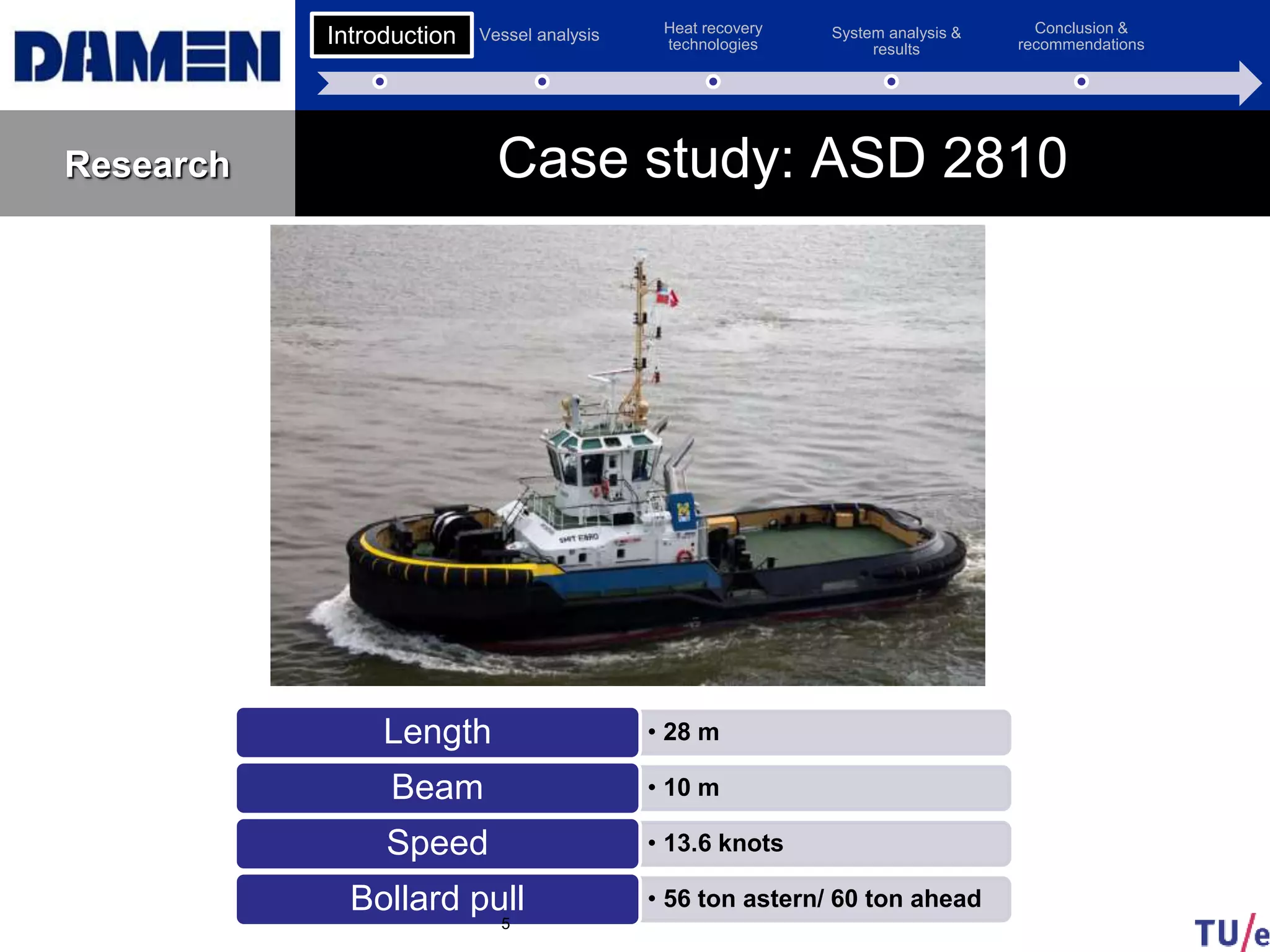

The document analyzes potential energy optimization opportunities for a vessel called the ASD-2810 through heat recovery. It begins with an introduction and overview of the research contents. Next, it performs a vessel analysis which examines the vessel's energy demands and waste heat supply sources. It then reviews various heat recovery technology options for heat, cooling, freshwater and electric supply. An example heat recovery scheme is presented and its potential fuel savings are analyzed for different system configurations and seasons. Key conclusions are that storage systems are important for continuous supply and an adsorption-based system using heat storage provides the largest fuel savings. A recommendation is made to develop a heat recovery optimization tool to help evaluate different component options.

![Introduction Vessel analysis Heat recovery

technologies

System analysis &

results

Conclusion &

recommendations

Research

6

Propulsion and electrical generation systems

Propulsion

Engine

3516-C

1864 kW @ 1600RPM

G

B

G

B

G

86 ekW

DE

93 bkW

G

86 ekW

DE

93 bkW

[440V,60Hz]SwitchBoard

Hotel load

Propulsion

Engine

3516-C

1864 kW @ 1600RPM

Introduction](https://image.slidesharecdn.com/370dc321-cbb1-4e23-93bf-8523035d90fe-151230133621/75/Friday-presentation-6-2048.jpg)