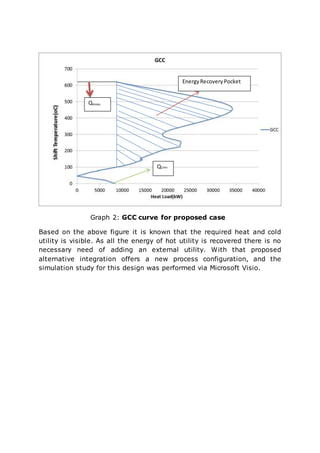

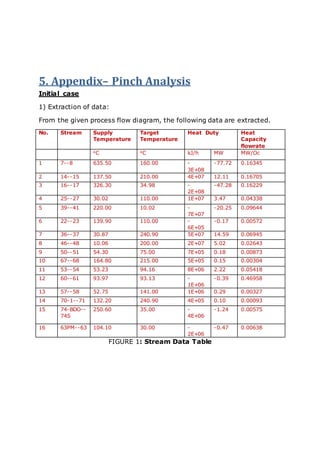

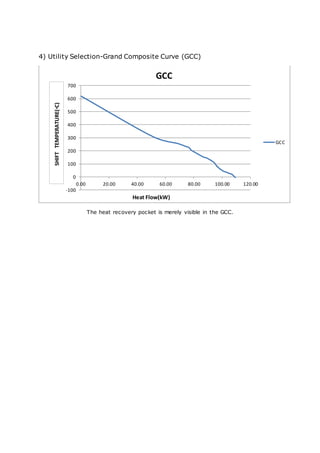

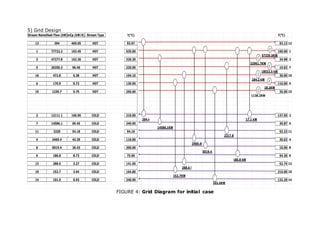

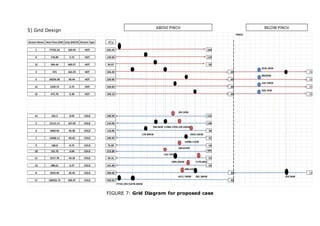

The document discusses a heat exchanger network synthesis project. It analyzes the heat flow of an industrial process initially and with a proposed heat integration case using pinch analysis. The initial case shows no heat recovery, while the proposed case introduces a cold utility and identifies a large heat recovery pocket. Utility savings of the proposed case are estimated at 98.2% compared to the initial case and base case without integration.