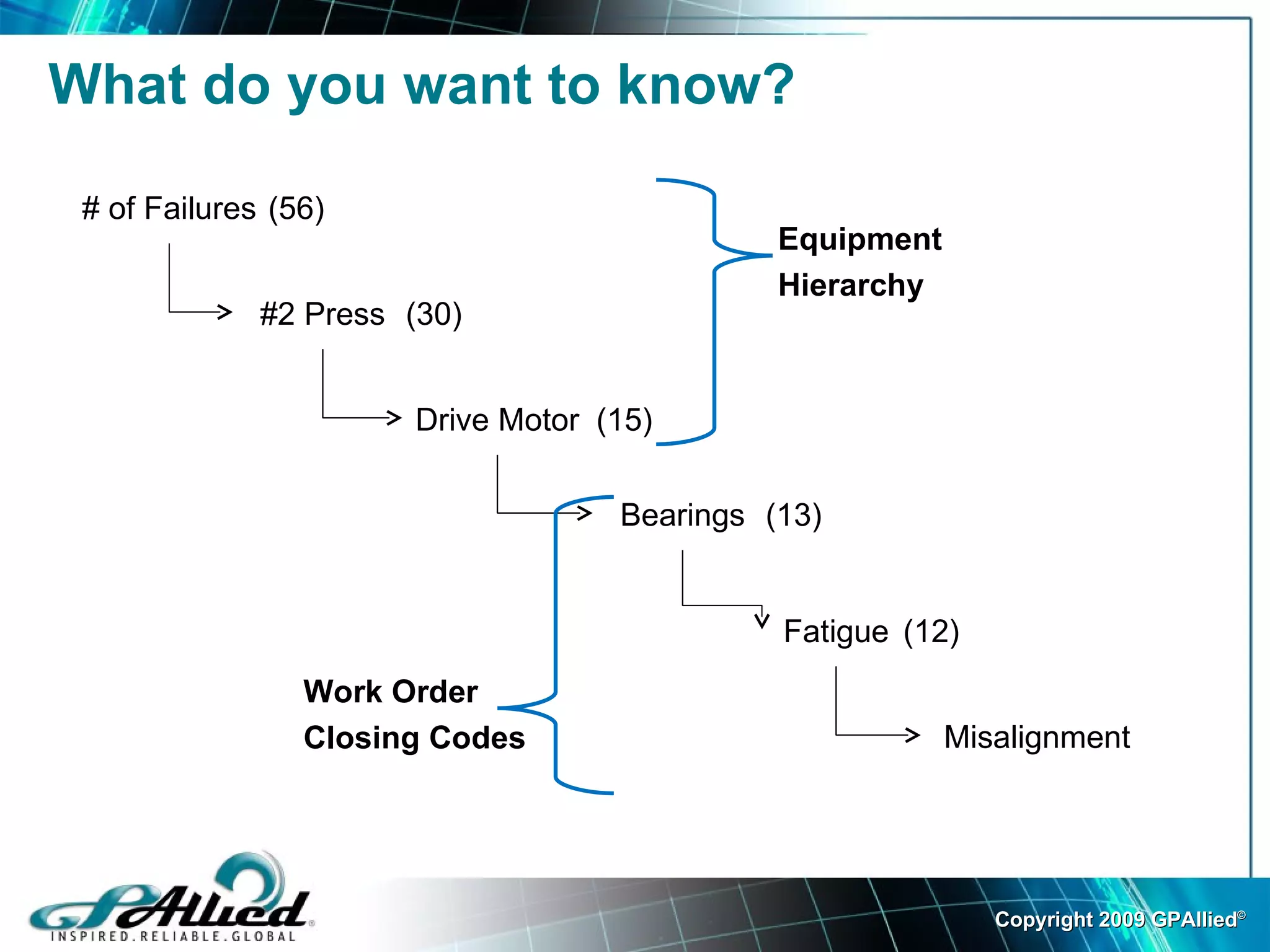

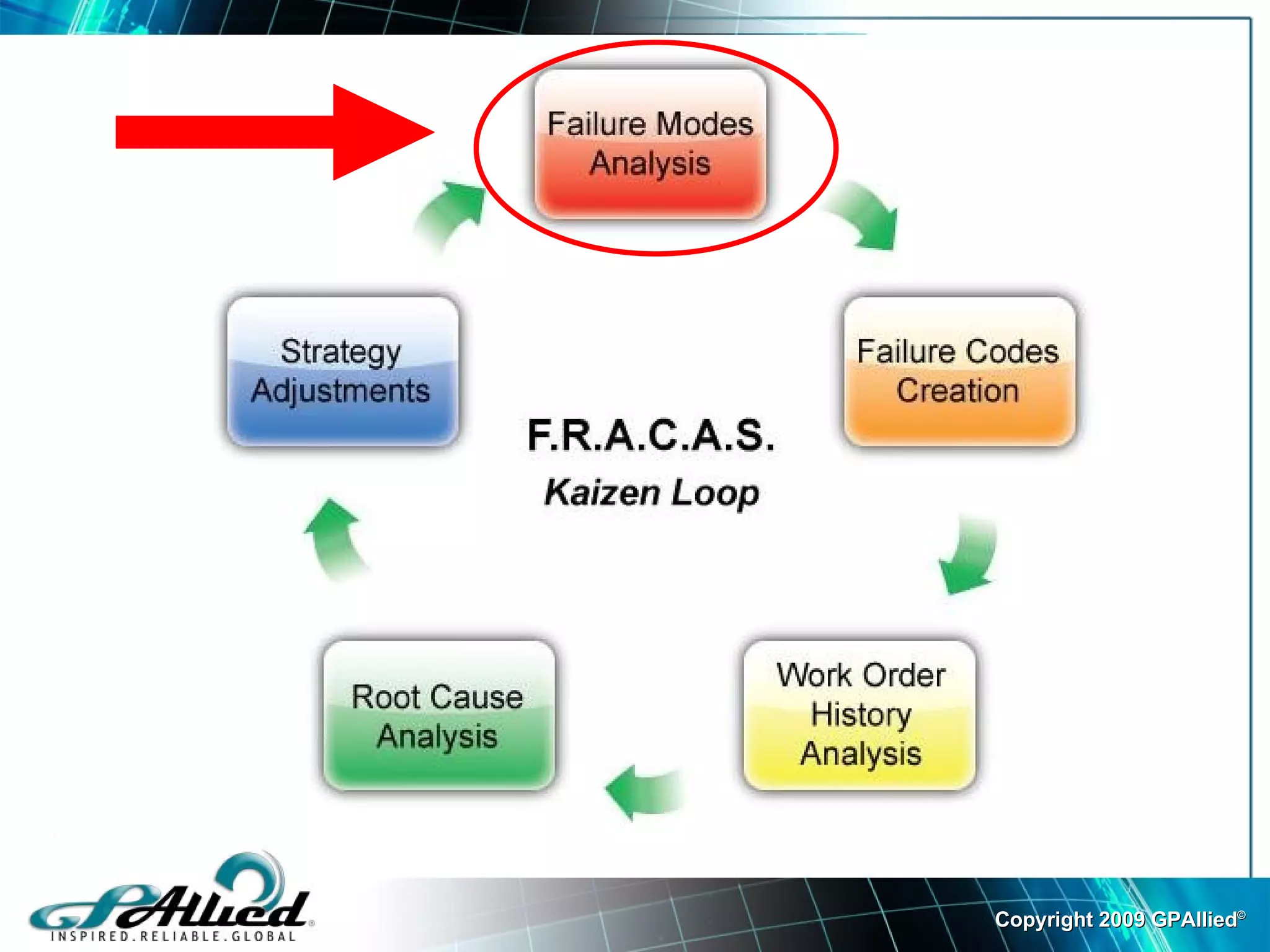

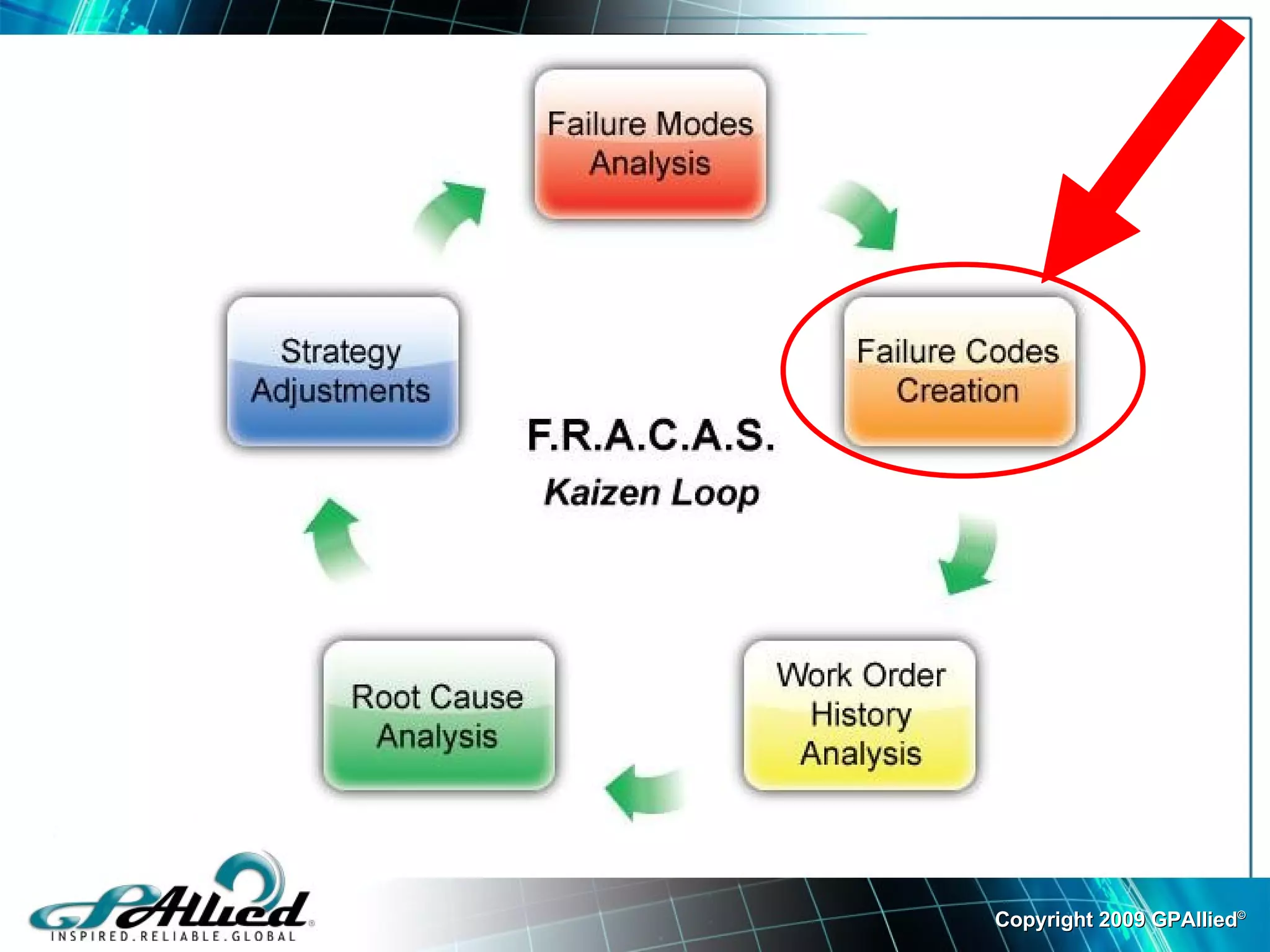

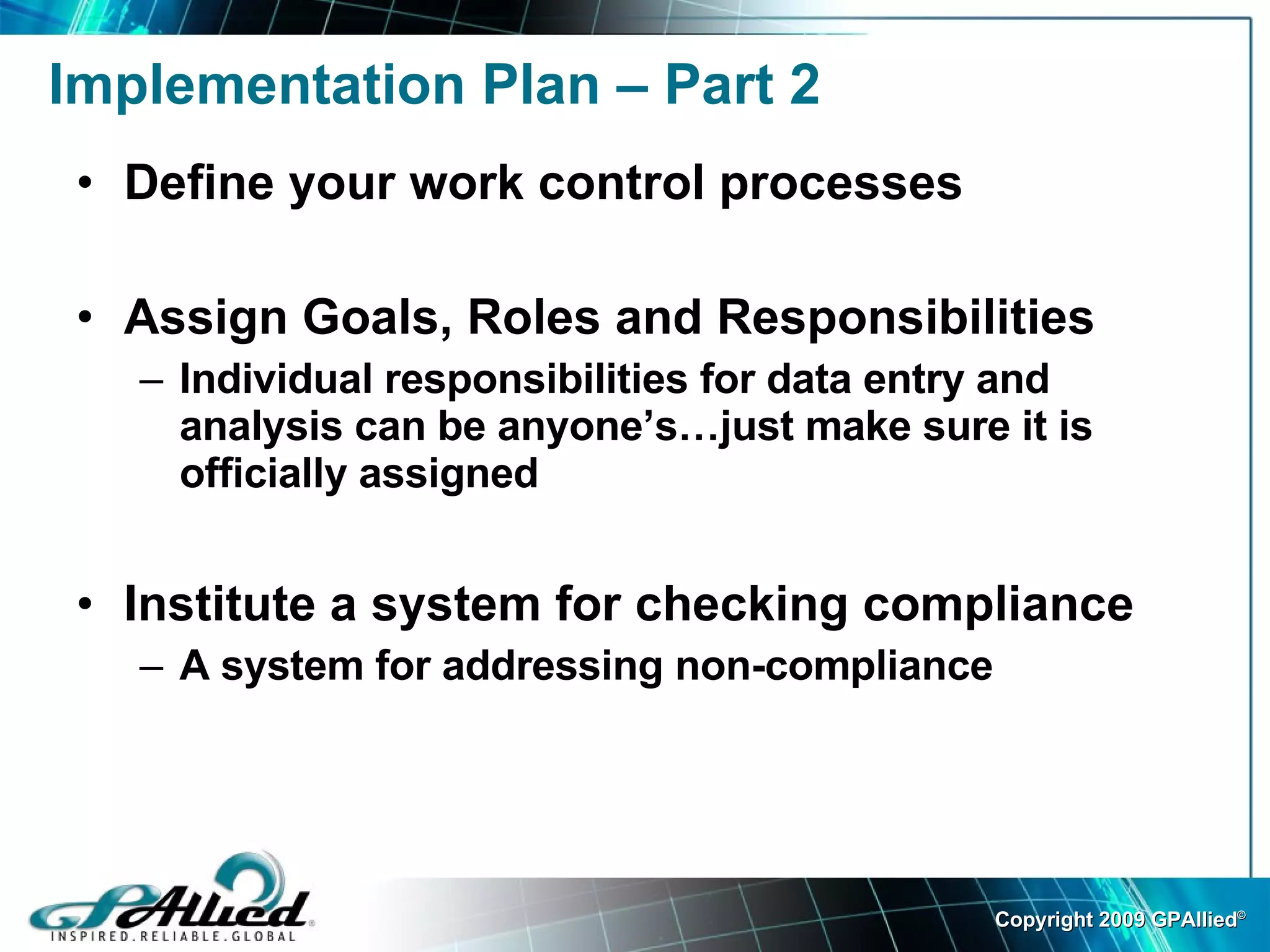

This document discusses Failure Reporting, Analysis and Corrective Action System (FRACAS), a system for recording equipment failures, analyzing patterns in failure data, and making business decisions based on conclusions. It outlines how to implement FRACAS using failure codes in a Computerized Maintenance Management System (CMMS) to identify top failure modes across equipment and implement corrective actions. The presentation notes biggest challenges are getting accurate failure analysis data recorded in the CMMS and completing the failure modes library, and provides a multi-step implementation plan starting with critical equipment.

![Phone is Listen Only During the Webinar….email questions to [email_address]](https://image.slidesharecdn.com/fracas-124205173311-phpapp02/75/FRACAS-Failure-Reporting-Analysis-Corrective-Action-System-3-2048.jpg)