- Soil sampling is done before construction to check the load bearing capacity and settlement of soil at a site.

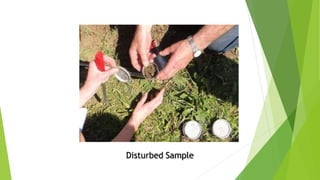

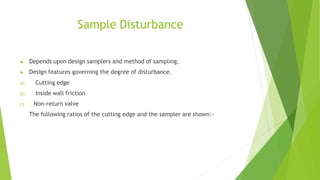

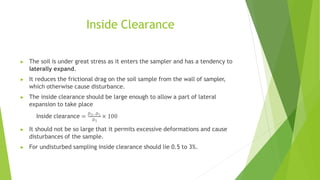

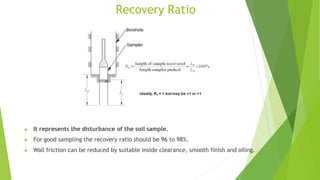

- There are different types of soil samples and sampling techniques that can be used depending on whether an undisturbed or disturbed sample is needed. Factors like sampling depth, tools, and procedure must be considered.

- It is important to properly identify and ship samples to determine the soil composition and properties, which informs foundation design and ensures structural stability based on the soil quality at that location.