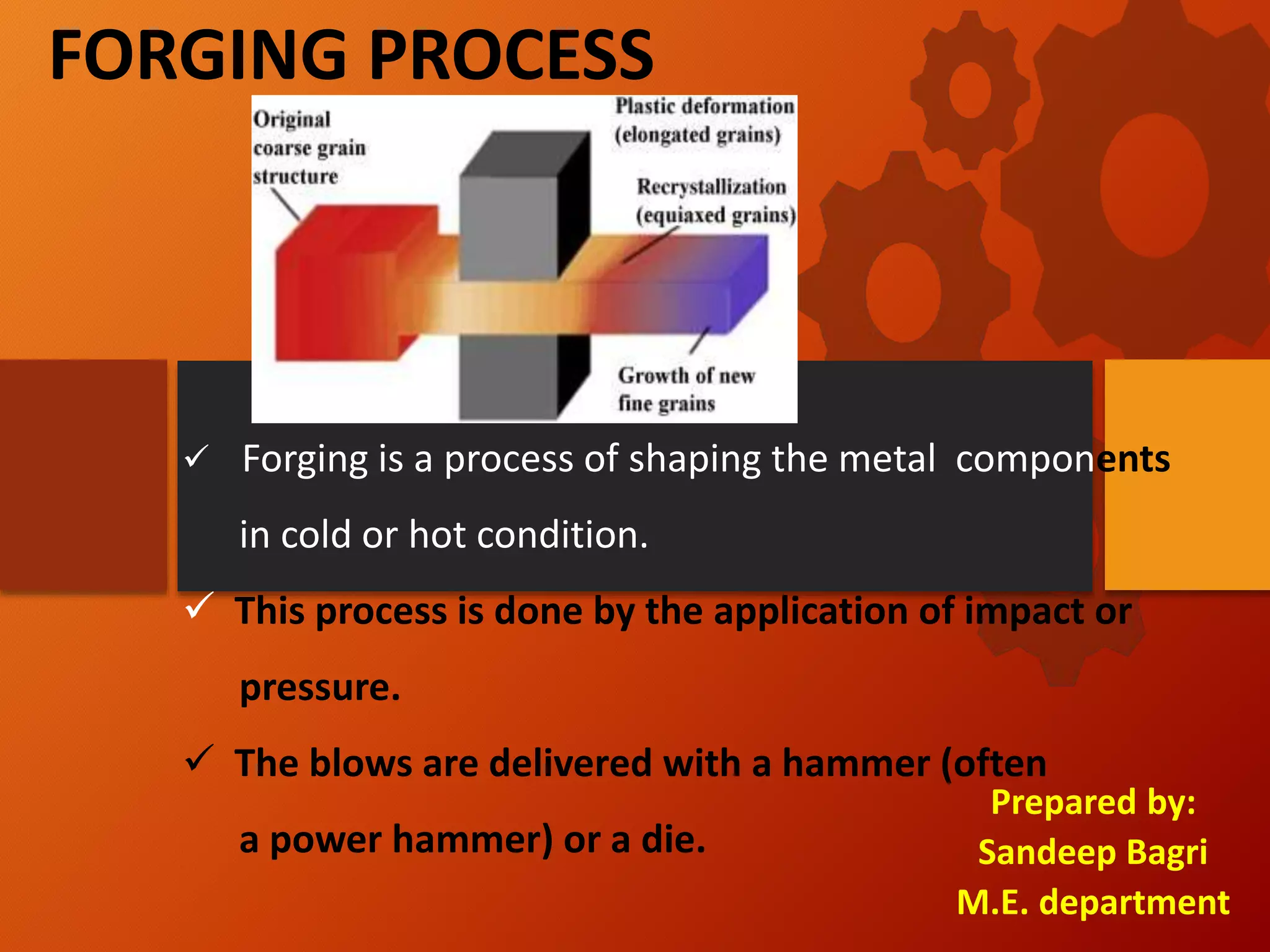

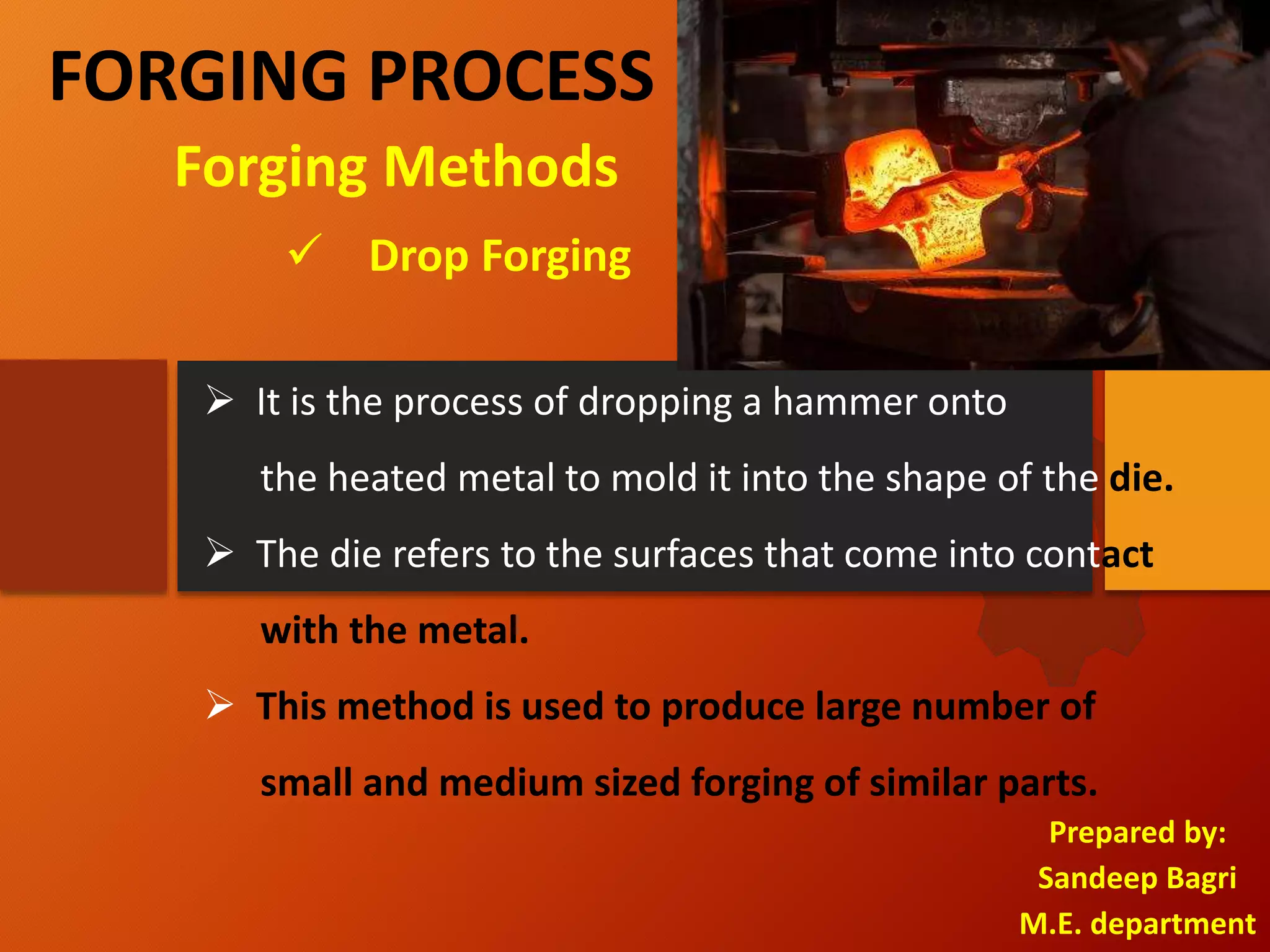

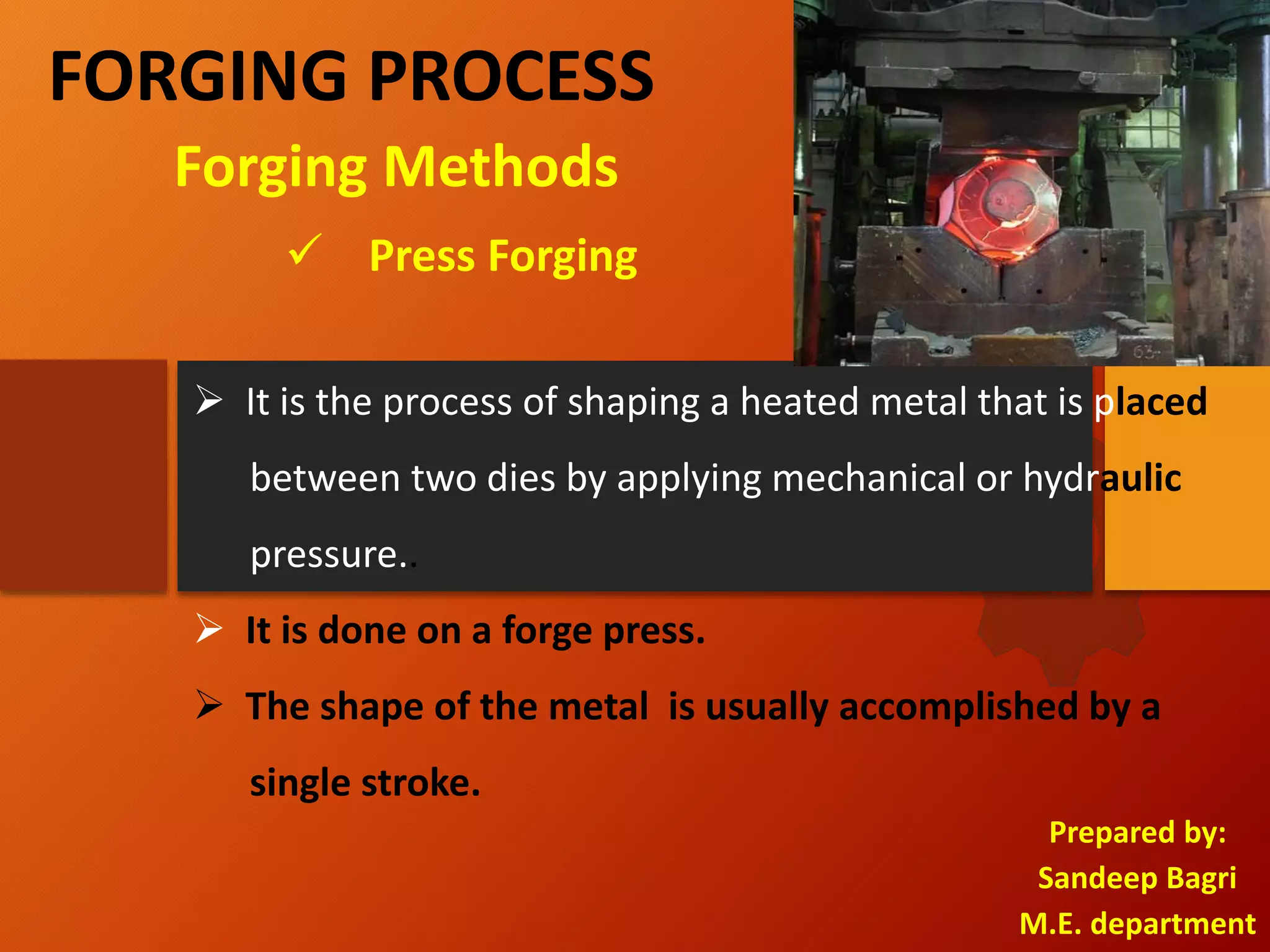

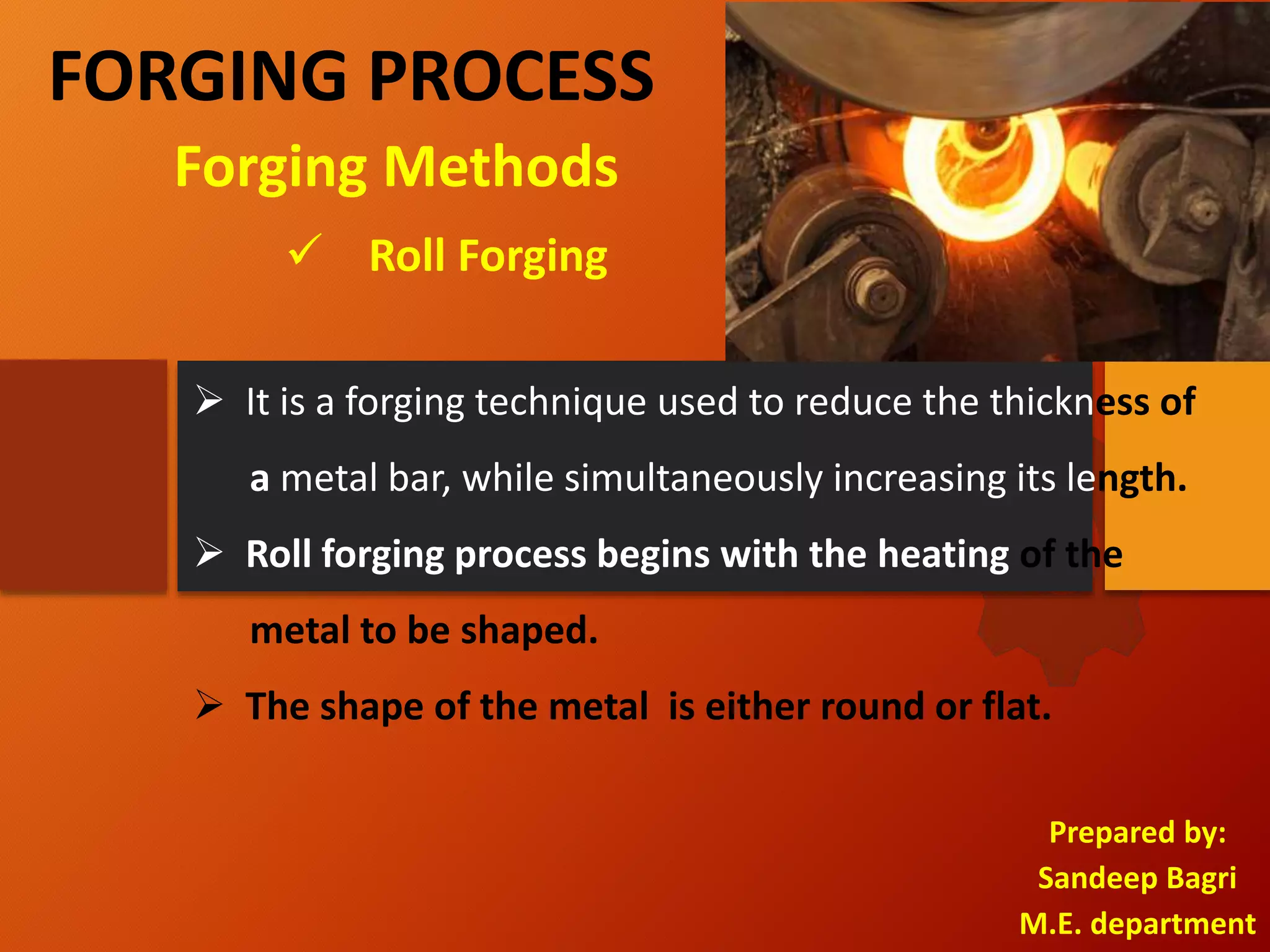

The document discusses the forging process, which involves shaping metal components through the application of impact or pressure while the metal is hot or cold. It describes several forging methods - hand forging involves heating metal and shaping it with hammers on an anvil, drop forging uses a hammer dropped onto heated metal in a die, press forging applies mechanical pressure between dies, and roll forging reduces thickness while increasing length through rolling. The document was prepared by Sandeep Bagri in the mechanical engineering department.