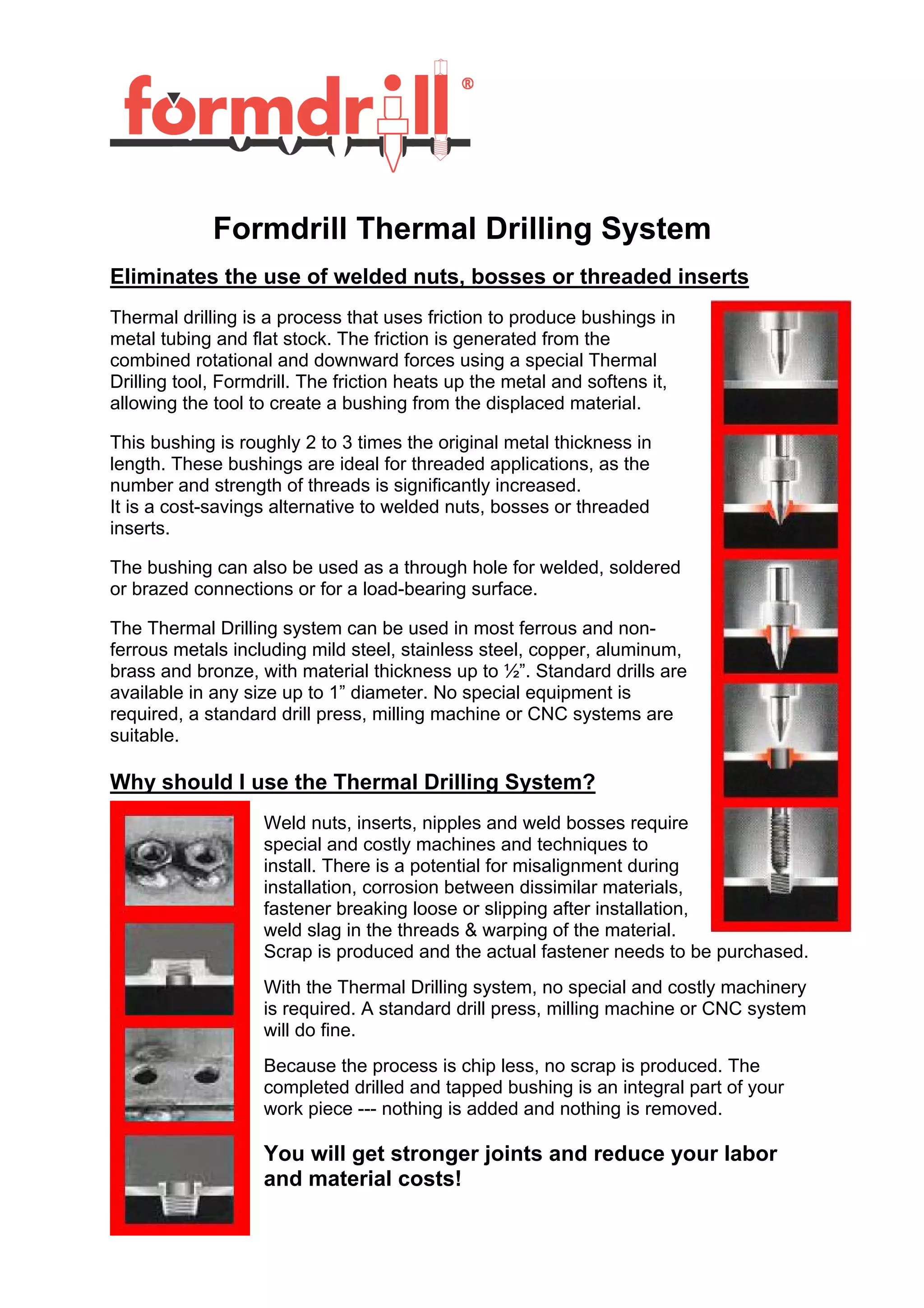

The Formdrill Thermal Drilling System uses friction generated by a rotating tool to bore bushings directly into metal materials up to 1/2 inch thick without welding, drilling, or inserting separate fasteners. The process strengthens threaded connections by creating an integral bushing that is 2-3 times the thickness of the original material. It provides a low-cost alternative to welded nuts, bosses or threaded inserts and eliminates the risks of misalignment or corrosion associated with joining dissimilar materials. The system can be used with most metals on standard drilling equipment and requires only a Thermal Drilling tool, collet, lubricant, and Formtap to cut threads in the bushing.