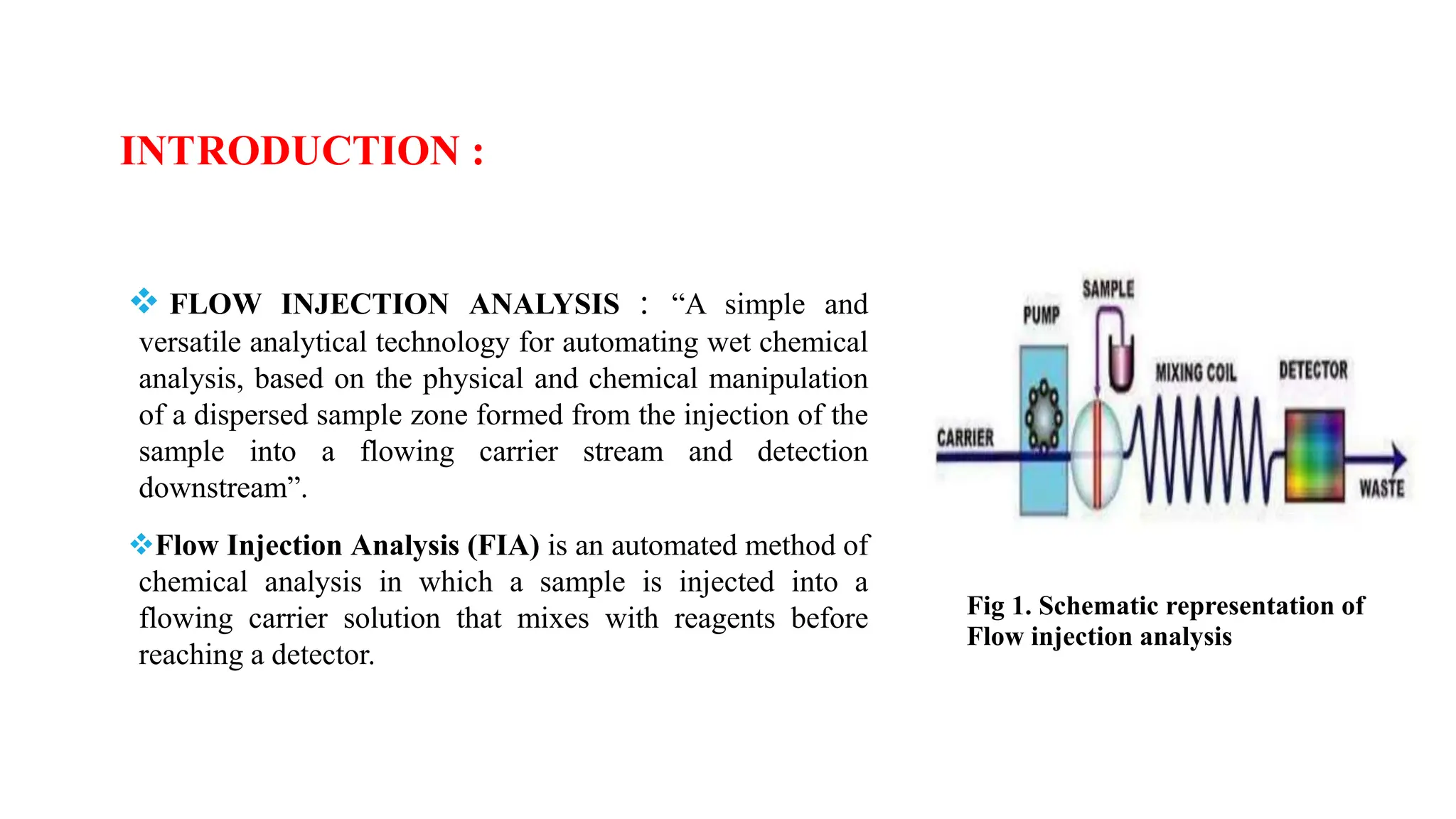

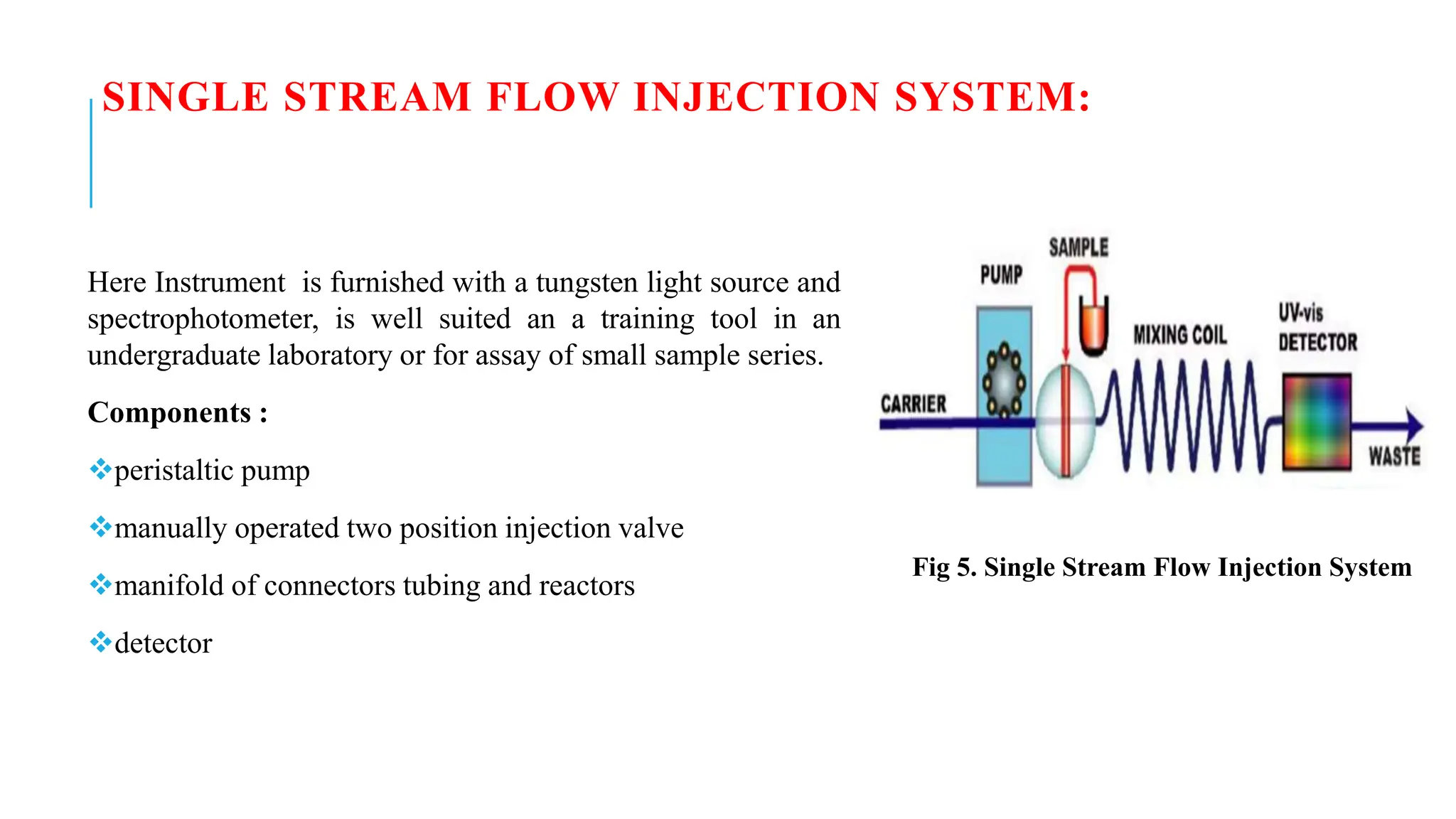

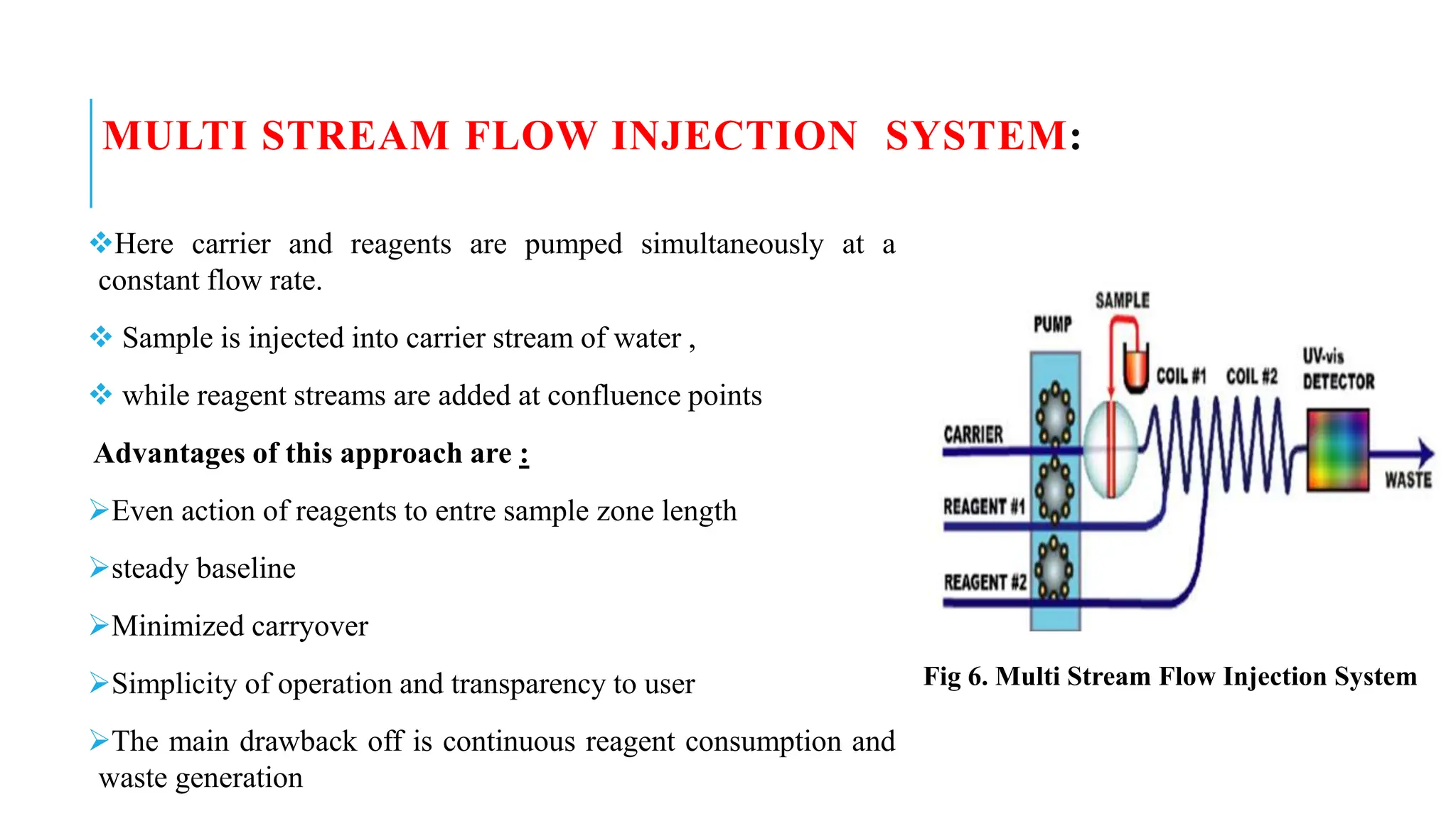

The document discusses flow injection analysis (FIA), an automated analytical technique that involves injecting a sample into a flowing carrier solution to mix with reagents before detection. It details the principles, instrumentation, types of FIA systems, and provides insights on the determination of phosphate using this method. The advantages include speed and reproducibility, while drawbacks involve potential unemployment due to automation.