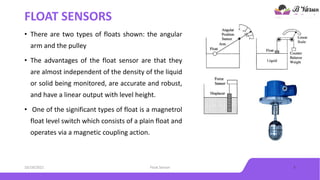

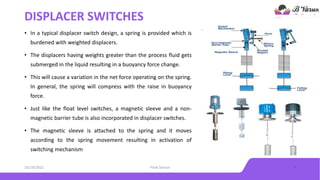

The document provides an overview of various level sensing devices, categorizing them into direct and indirect sensing methods, as well as single point measurements. It discusses different types of float sensors, displacer switches, conductive and capacitive probes, ultrasonic and radar measurement techniques, highlighting their advantages and limitations. The information covers applications, operational principles, and considerations for selecting appropriate sensors for liquid level measurement.